Patents

Literature

45results about How to "Strong process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Processing method of low blood glucose index preserved mango fruits with effect of regulating intestinal function

ActiveCN104381559APromote natural proliferationGood for healthConfectionerySweetmeatsBiotechnologyMango fruit

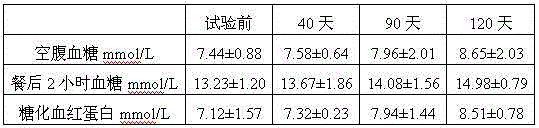

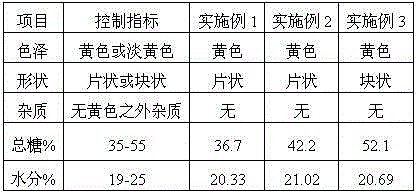

The invention discloses a processing method of low blood glucose index preserved mango fruits with effect of regulating the intestinal function. The processing method sequentially comprises the following steps: fruit selecting, fruit cleaning and slicing, color-protecting, sugaring, secondary powder-wrapping and drying, wherein the sugaring process adopts L-arabinose for sugaring for 24-48 hours; the secondary powder-wrapping adopts a mixture of 80-95% of L-arabinose and 5-20% of oligosaccharide. The sugaring processing process of the preserved mango fruits processed by the processing method disclosed by the invention can keep the mouthfeel, and also has good effects of lowering the blood glucose index, restraining the development of hyperglycemia and relieving the pathogenetic condition of a patient with hyperglycemia.

Owner:AGRI PROD PROCESSING INST GUANGXI ACADEMY OF AGRI SCI +1

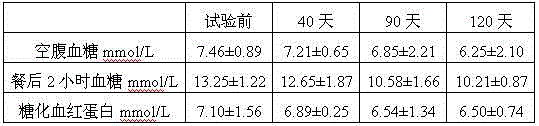

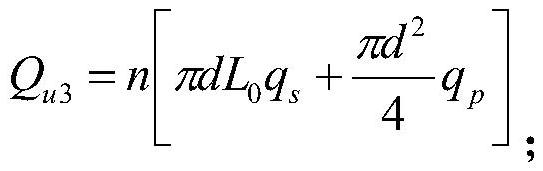

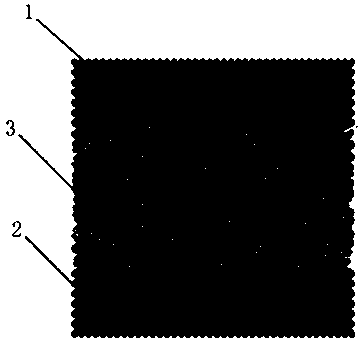

Preparation method of MLA resin film serving as ore powder sample

InactiveCN106769311AStrong representativeIncreased dispersionPreparing sample for investigationMaterials scienceCuring time

The invention discloses a preparation method of an MLA resin film serving as an ore powder sample. The preparation method comprises the following steps: sample pretreatment, first-time cold inlaying, second-time cold inlaying, and grinding and polishing. According to the preparation method disclosed by the invention, by adopting a process of the sample pretreatment, the first-time cold inlaying, the second-time cold inlaying, and the grinding and polishing and two inlaying of the powder sample in sequence, high representativeness and high dispersion degree of sample granules are guaranteed; according to the ratios of resin and a curing agent, enough operation time can be guaranteed; meanwhile, standing and curing time of a resin sample is shortened; the whole flow has the advantages of short process flow, obvious effect, high practicality and low cost.

Owner:KUNMING METALLURGY INST

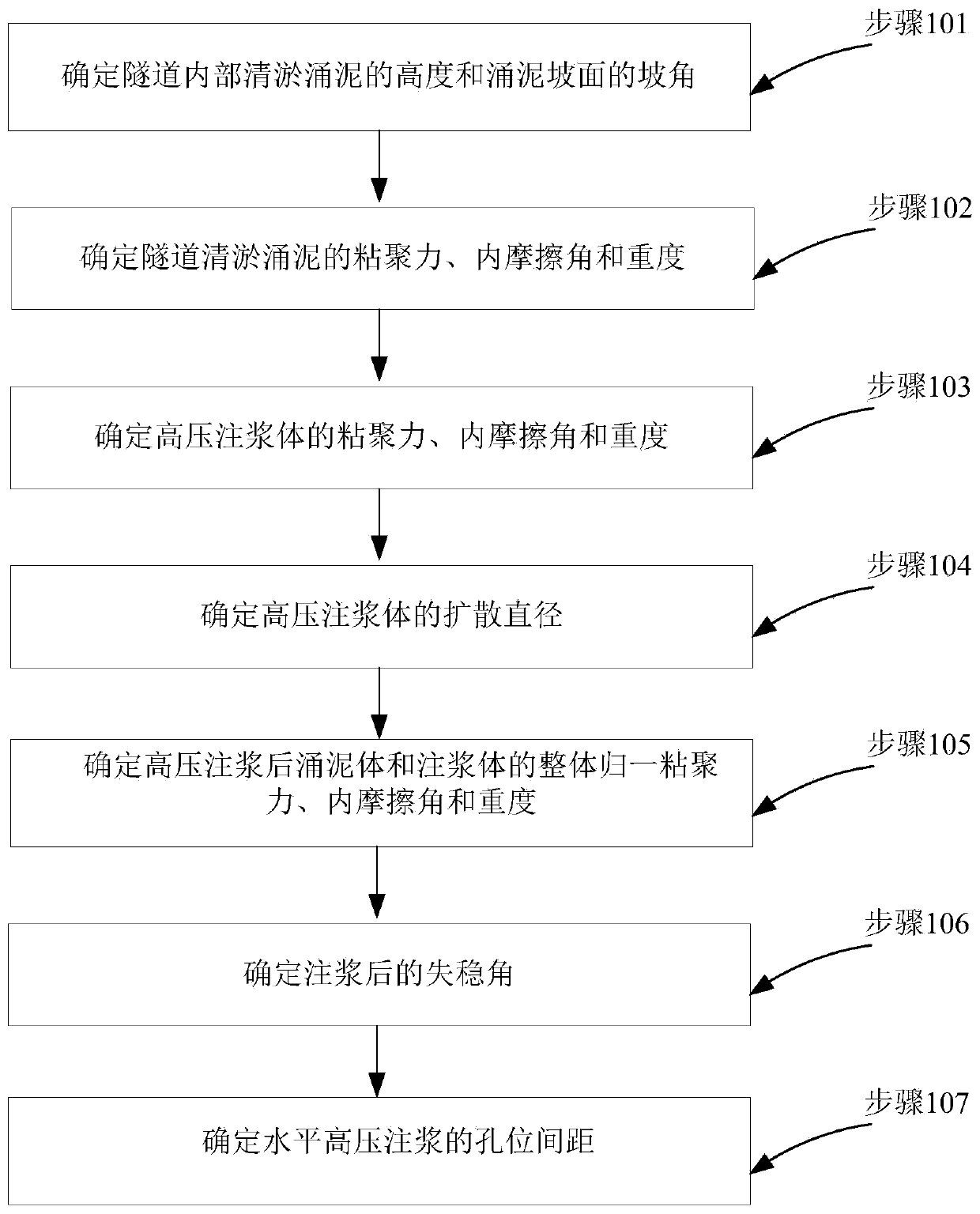

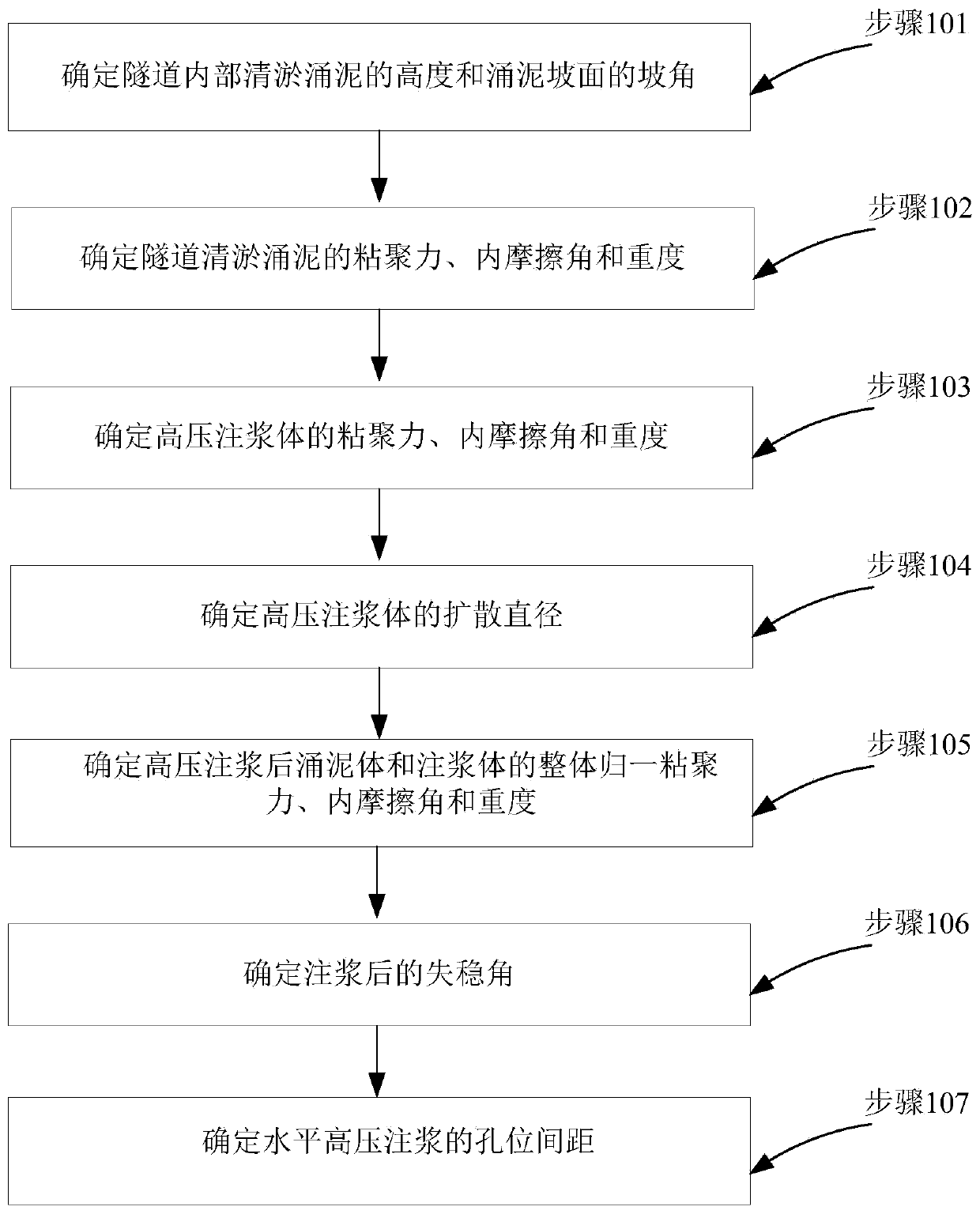

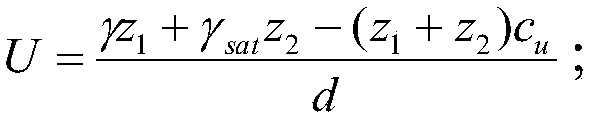

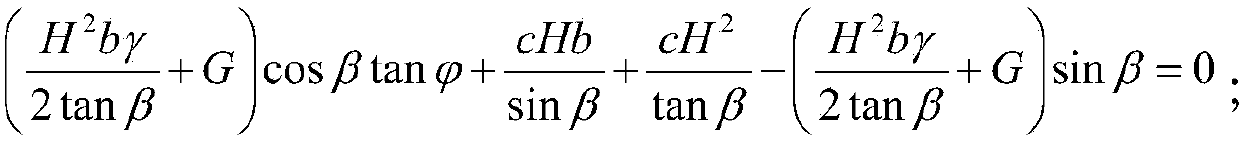

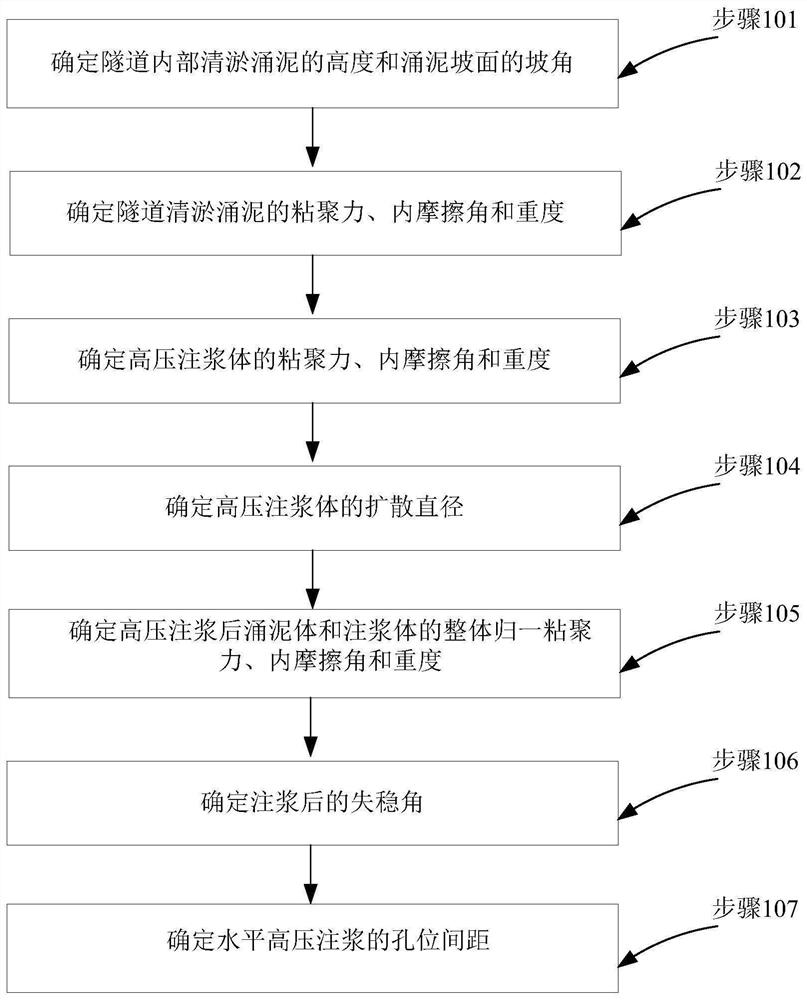

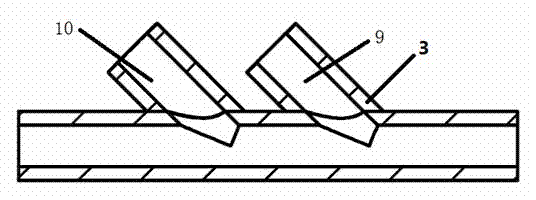

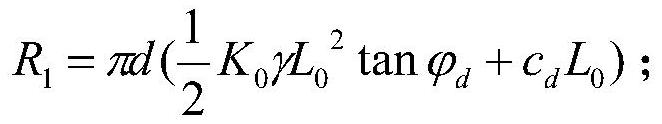

Hole position space prediction method for tunnel gushing mud desilting horizontal high-pressure grouting

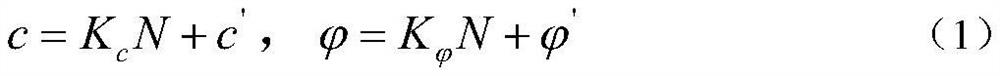

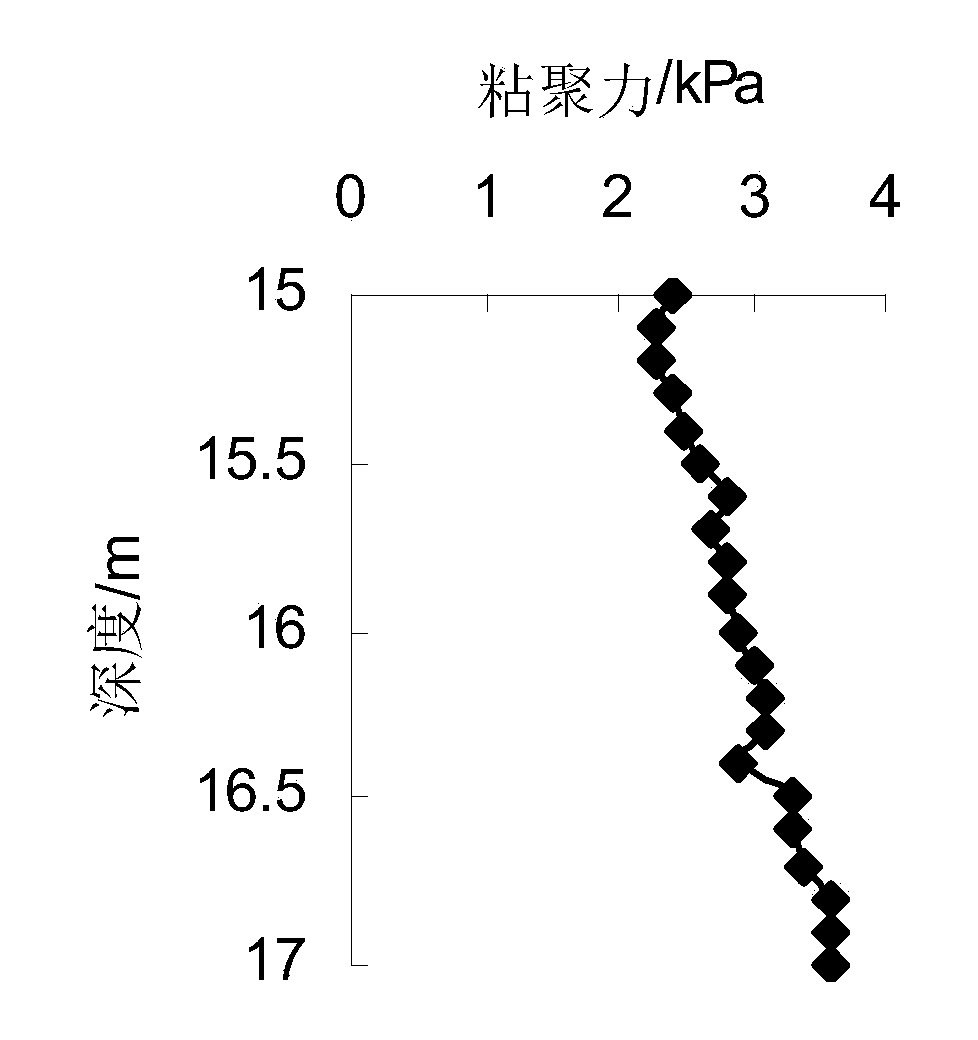

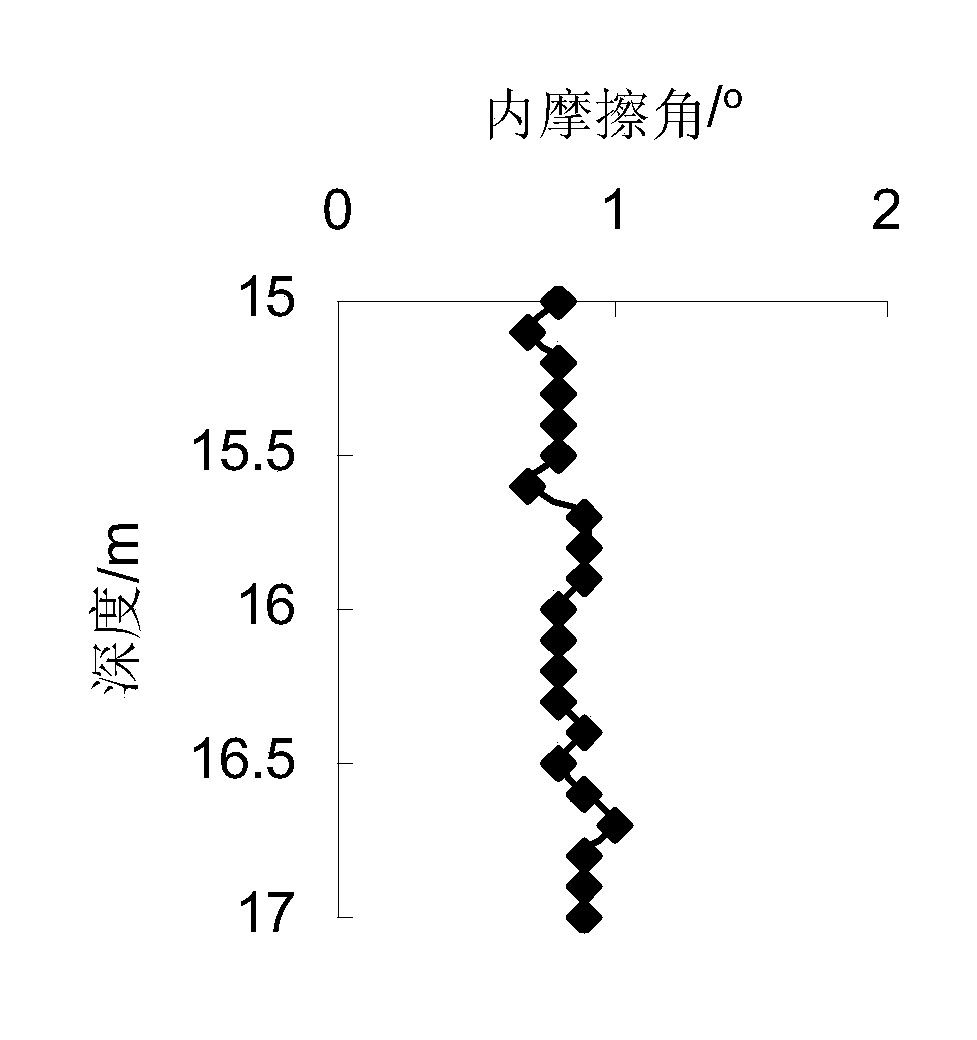

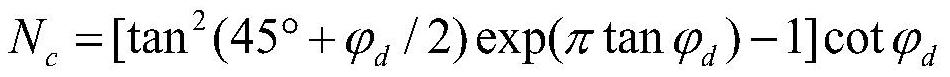

ActiveCN109855987AStrong processEasy to implementFlow propertiesMaterial strength using steady shearing forcesSlope angleFriction angle

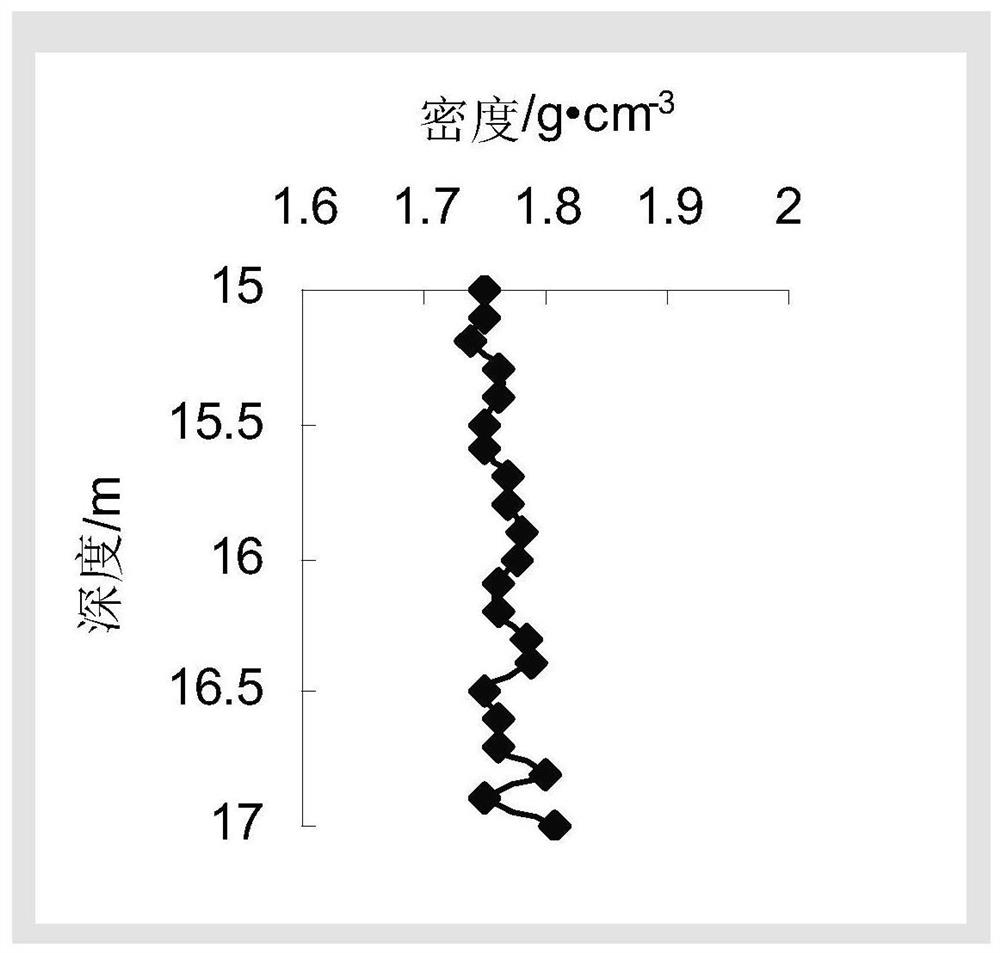

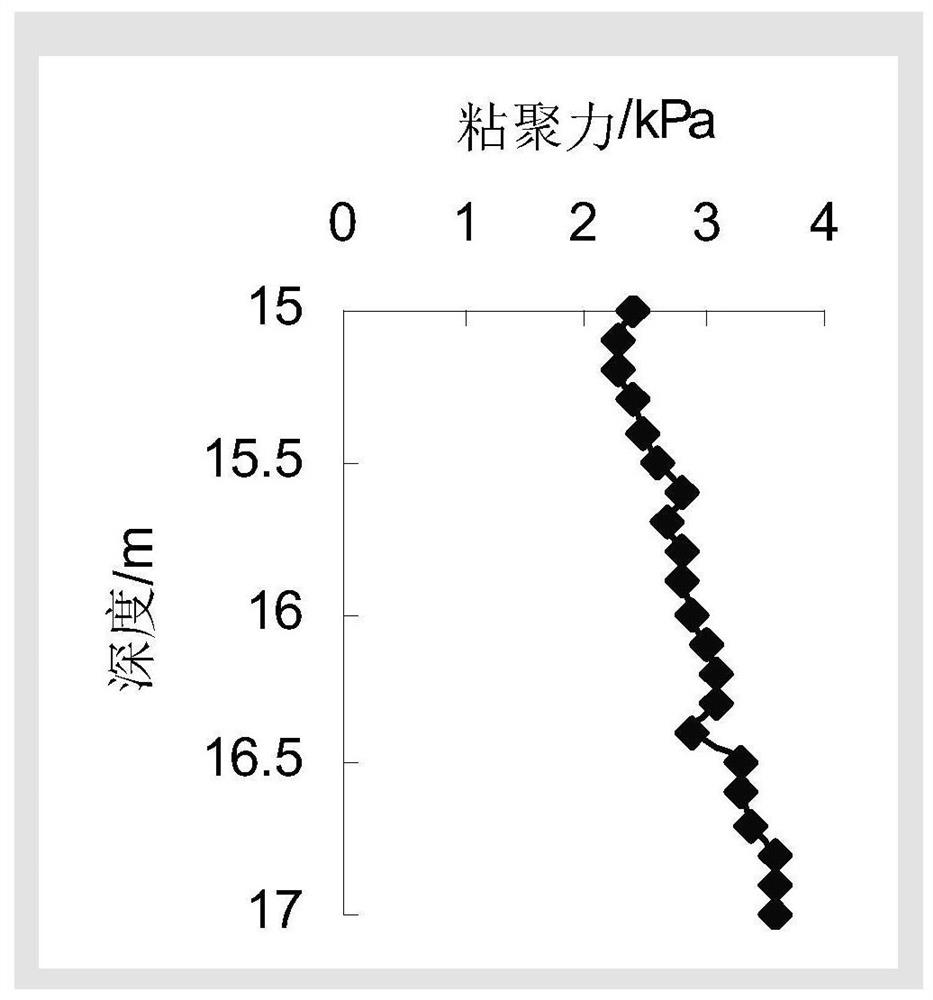

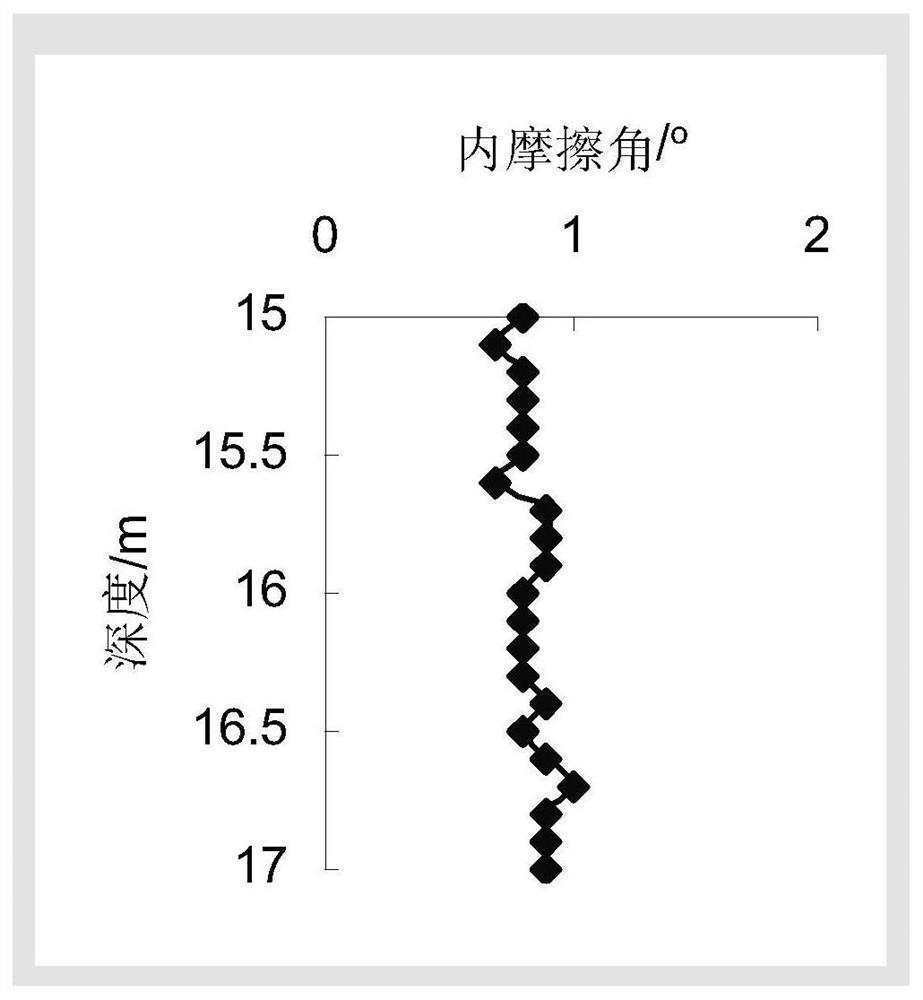

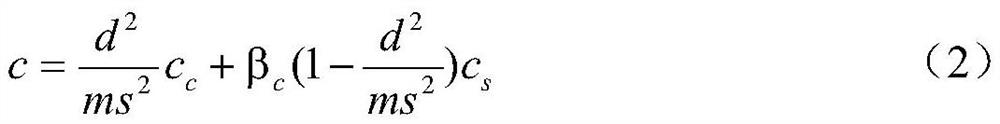

The invention relates to a hole position space prediction method for tunnel gushing mud desilting horizontal high-pressure grouting. The method comprises the following steps of determining the desilting gushing mud height H inside a tunnel and a slope angle alpha of a gushing mud slope surface; determining the cohesive force c<s>, the inner friction angle phi<s> and the weight r<s> of the tunnel desilting gushing mud; determining the cohesive force c<c>, the inner friction angle phi<c> and the weight r<c> of a high-pressure grouting body; determining the diffusion diameter d of the high-pressure grouting body; determining the integral normalized cohesive force c, the inner friction angle phi and the weight r of the grouting body and a gushing mud body after the high-pressure grouting; determining the unstability angle phi' after the grouting; and determining the hole position space s of the horizontal high-pressure grouting. The hole position space prediction method for the tunnel gushing mud desilting horizontal high-pressure grouting has the advantages that the flow process performance is high; the implementation is convenient; and the result is reliable.

Owner:HUAQIAO UNIVERSITY

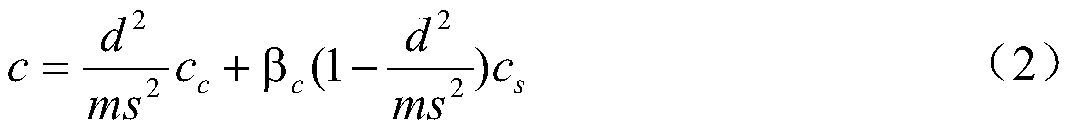

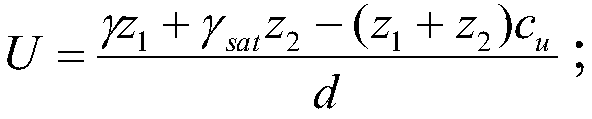

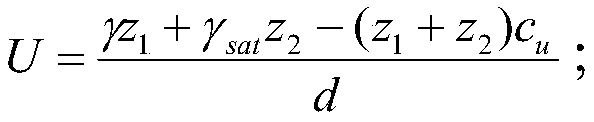

Predication method for depositing length of gushing mud in water-bursting and mud-bursting hole of tunnel

The invention provides a predication method for the depositing length of gushing mud in a water-bursting and mud-bursting hole of a tunnel. The predication method comprises the seven steps of: calculating out natural unit weight Gamma of a soil body and underwater saturation unit weight Gamma sat, measuring and calculating a buried depth z1 of underground-water level and a distance z2 from the underground water level to a tunnel arch crown, measuring the shape and size of a water-bursting and mud-bursting breach to obtain cross-section area A of the water-bursting and mud-bursting breach and measuring the undrained shear strength cu and the like. By application of the technical scheme, the use is simple and convenient, the process characteristic is strong, and the result is reliable, so that the water-bursting and mud-bursting disasters can be effectively prevented.

Owner:HUAQIAO UNIVERSITY

Method for predicting the formation time of surface collapse of water inrush and mud inrush of a tunnel

ActiveCN109583047AEasy to useStrong processHydro energy generationDesign optimisation/simulationSoil scienceFracture zone

The invention provides a method for predicting the formation time of surface collapse of water inrush and mud inrush of a tunnel. The method includes the following steps: 1) calculating the buried depth H of the water inrush mud; 2) calculating the equivalent diameter D of the cross section of the tunnel fracture zone; 3) calculating the natural gravity of the soil within the fracture zone in thefracture zone , cohesion force c and internal friction angle, 4) Calculating the undrained shear strength cu of the soil within the fracture zone and the surrounding surrounding rock; 5) Calculating the breaking band at the unit height, the critical shear strength due to the looseness of the soil cu, cri, 6) Calculating The critical ratio r when falling of the fracture zone, wherein r=cu, cri / cu;7) Calculating the time required for the unit height to break down the belt t, wherein t=1.06r-16.85; 8) Calculating from the beginning of the water inrush Surface subsidence Time T, wherein T = tH. The invention provides a method for predicting the formation time of a tunnel water inrush mud surface, which has the advantages of simple use, strong process and reliable results.

Owner:HUAQIAO UNIVERSITY

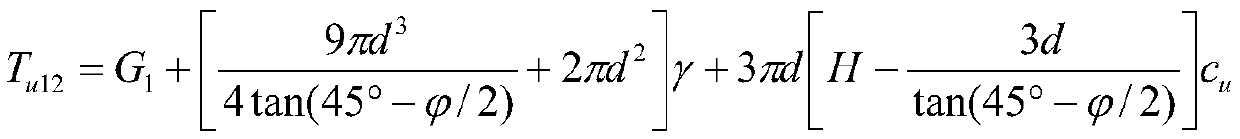

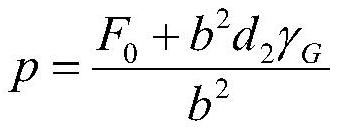

Confined water stratum foundation pit bottom soil layer pile foundation reinforcing pile distance and pile length prediction method

PendingCN110080317ASimple structureStrong processFoundation testingIn situ soil foundationPile capConfined water

The invention relates to a confined water stratum foundation pit bottom soil layer pile foundation reinforcing pile distance and pile length prediction method which is suitable for the field of foundation construction and comprises the following steps that stratum distribution in a site is determined; geological drilling is conducted in the site, the stratum distribution of the site is revealed, and the thickness of the soil body of the ith layer is obtained by the formula in the specification; the pressure of confined water is determined; the undrained shear strength and the weight of the soil body overlying each soil layer on the confined water of the site are determined; the weighted average undrained shear strength of the stratum soil body overlying the confined overwater according tothe depth, and the weighted average weight according to the depth are determined, wherein (please see the formula in the specification); the diameter of a driven pile foundation and the side length ofa pile cap are determined according to construction conditions; a pile distance is determined; the limit side friction force between the pile foundation and the confined water soil body is determined; and the length of the pile foundation is determined. The prediction method has the advantages of being high in process property and convenient to implement.

Owner:FUJIAN UNIV OF TECH

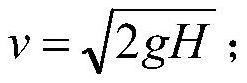

Method for predicting impact force of submarine landslide collapse block on submarine pipeline

ActiveCN112734081AStrong processEasy to useForecastingDesign optimisation/simulationStructural engineeringSubmarine pipeline

The invention relates to a method for predicting the impact force of a submarine landslide collapse block on a submarine pipeline, and the method comprises the steps: the cohesive force and internal friction angle of a soft soil body are gradually reduced below a hard layer under the action of a wave cyclic load to a critical value, the submarine landslides, the hard layer slides downwards and is torn into a collapse block, and slides towards the downside of a slope; firstly, the bottommost collapse block impacts the submarine pipeline, the instant impact force of the collapse block impacting the submarine pipeline is determined according to the momentum theorem, after the impact force is completed, the collapse block acts on the submarine pipeline in a static thrust mode, then the second row of collapse blocks impact the first row of collapse blocks, and the impact force acts on the submarine pipeline; and after the impact force is finished, the first row of collapsed blocks and the second row of collapsed blocks act on the submarine pipeline in a static thrust mode until the last row of collapsed blocks impact the submarine pipeline, and force in two modes of instant impact force and static thrust acts on the submarine pipeline.

Owner:FUJIAN UNIV OF TECH

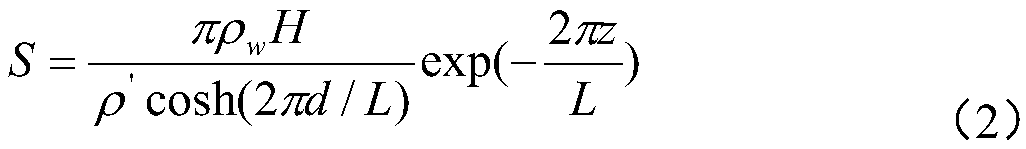

Method for predicting rock sinking depth of breakwater under action of waves

ActiveCN109631727AEffective calculation of subsidence depthPrediction is simpleMechanical depth measurementsMaterial strength using steady shearing forcesDesign methodsSubsidence

The invention discloses a method for predicting the rock sinking depth of breakwater under the action of waves. By an ingenious and precise design method, quantitative comparison on the sinking pressure of block stone and the ultimate bearing capacity after a foundation is softened, so that the rock sinking depth of the breakwater under the extreme sea condition wave action can be effectively measured, the blank of an existing subsidence depth measuring method is filled, and great significance is achieved for knowing the foundation burying depth, the design elevation and the size of breakwater.

Owner:HUAQIAO UNIVERSITY

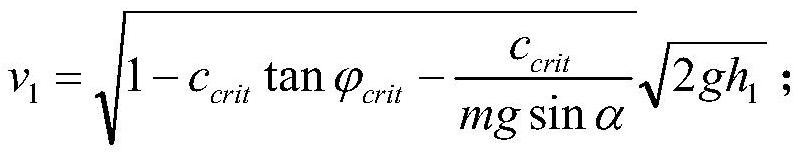

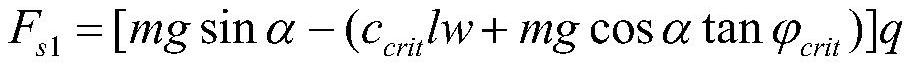

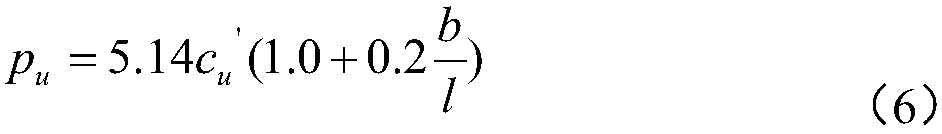

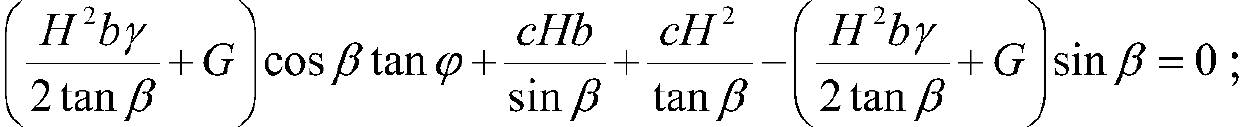

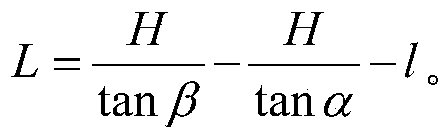

Method for predicting safe distance of soil dumping of slag truck at soil slope top

The invention provides a method for predicting the safe distance of soil dumping of slag truck at a soil slope top. The method comprises the following steps: (1), determining the spacing l between front and rear tires of a slag truck and a width b between tires at the two sides; (2), determining the total weight G of the slag truck loaded with soil; (3), determining a height H and a slope angle alpha of the soil slope; (4), determining engineering properties, including a weight gamma, an cohesive force c, and an internal friction angle, of the soil of the soil slope; (5), determining a slide angle beta based on a Matlab computer program or trial algorithm; and (6), determining a safety distance L from the rear tire to the shoulder of the slag truck based on a formula. The method has advantages of simple use, good flowing performance and high result reliability.

Owner:PUTIAN UNIV

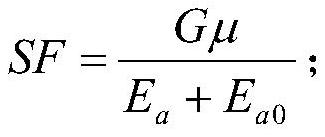

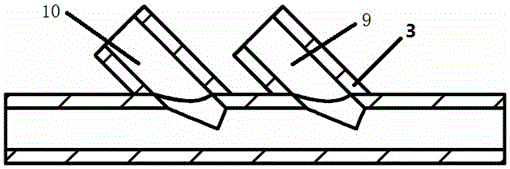

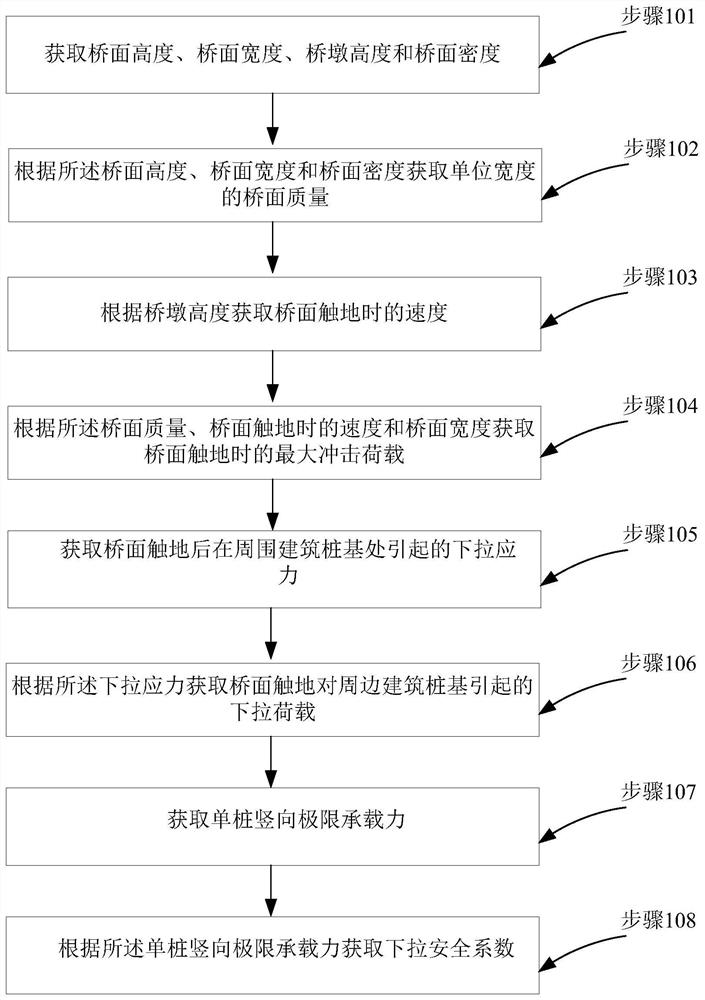

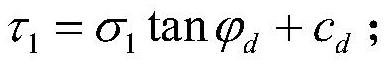

Anti-sliding safety prediction method for impact on shoreside retaining wall when bridge floor touch ground

ActiveCN112945761AStrong processSimple structureComponent separationMaterial strength using steady shearing forcesStable statusArchitectural engineering

The invention provides an anti-sliding safety prediction method for impact on shoreside retaining wall when a bridge floor touches the ground. The method comprises the following steps: determining a horizontal additional force generated in unit width of a wall back at the moment when the bridge floor touches the ground; determining soil pressure in unit width of the retaining wall; the anti-sliding safety coefficient SF of the retaining wall is determined; if the SF is greater than or equal to a set threshold value, judging that the retaining wall is in a stable state, otherwise, judging that the retaining wall slips and is damaged. The method has the advantages of being high in process, simple in structure and reliable in result.

Owner:FUJIAN UNIV OF TECH

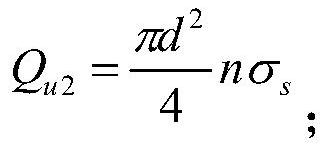

A foundation bolt uplift bearing capacity measuring and calculating method

ActiveCN109740197AThe method steps are simpleStrong processPhotovoltaic energy generationSpecial data processing applicationsBearing capacityBuilding construction

The invention discloses a method for measuring and calculating uplift bearing capacity of a foundation bolt. The method is used for measuring and calculating the ultimate uplift bearing capacity and the designed uplift bearing capacity of the foundation bolt for connecting a solar photovoltaic support and a foundation soil body. The method is simple in step, high in process flow and convenient touse, is more accurate and effective compared with a traditional method for determining the uplift bearing capacity of the foundation bolt according to experience, facilitates construction safety of the solar photovoltaic support in engineering building construction, and effectively avoids waste of connecting materials.

Owner:HUAQIAO UNIVERSITY

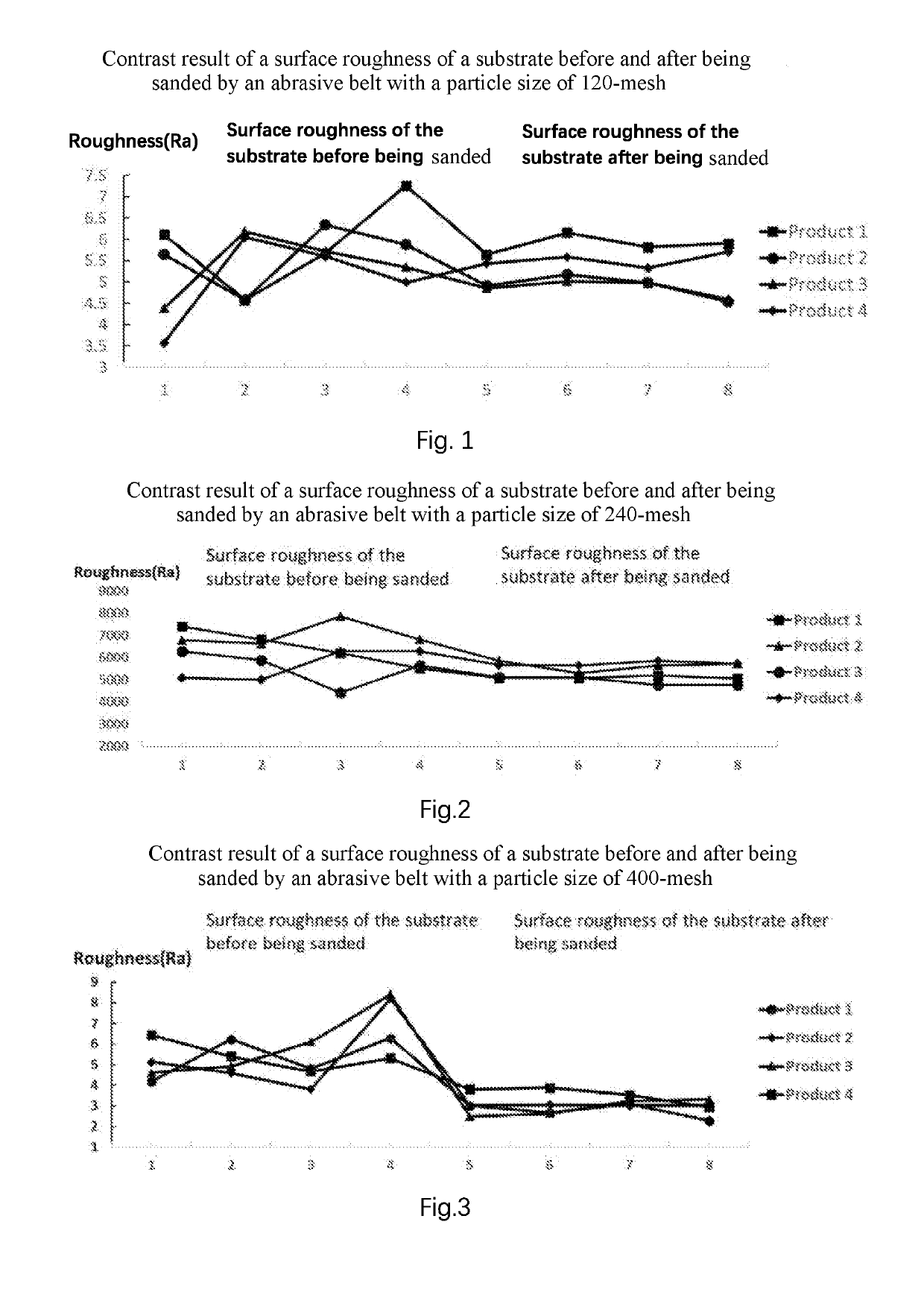

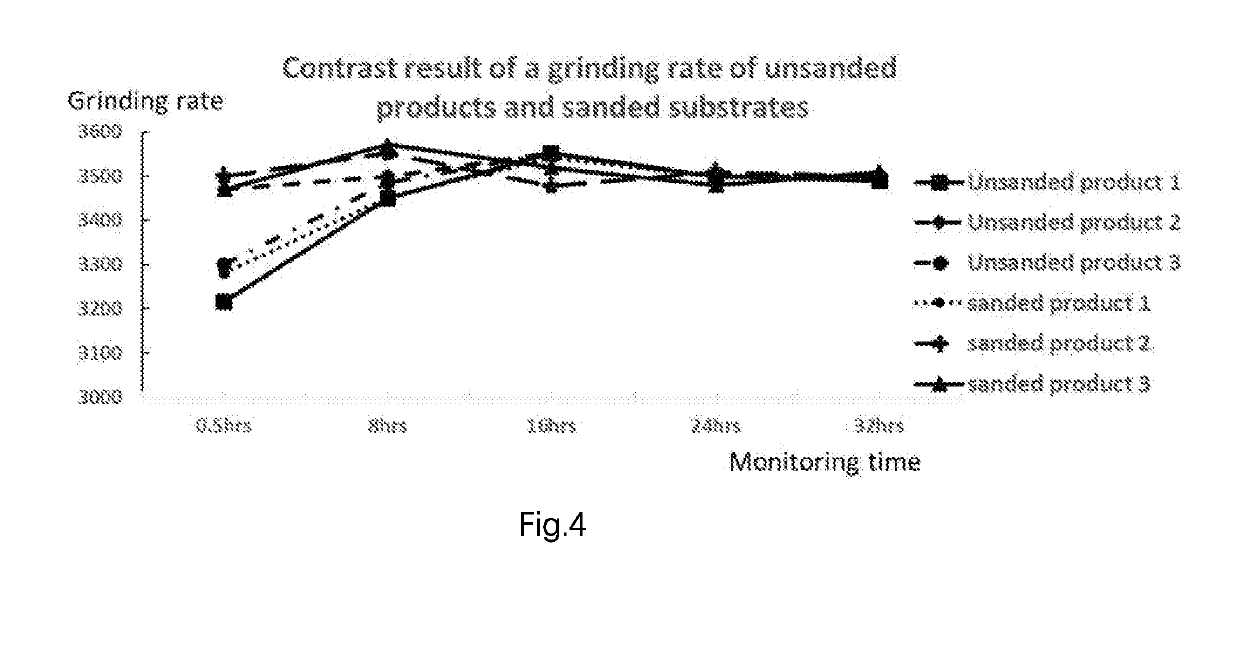

Surface treatment process of CMP Polishing pad

InactiveUS20190105752A1Improve stabilityEasy to operateBelt grinding machinesAbrasion apparatusSurface finishingMaterials science

A surface treatment process of a CMP (chemical mechanical polishing) polishing pad includes steps of rough-machining, fine-machining and finish-machining a substrate in sequence with an abrasive belt with a particle size of 120-mesh, an abrasive belt with a particle size of 240-mesh and an abrasive belt with a particle size of 400-mesh, respectively till a target thickness of the substrate is obtained. In each processing stage, the surface of the substrate is sanded through effectively adjusting the height of the corresponding abrasive belt so as to effectively control a surface roughness of the substrate. Moreover, through the surface treatment process provided by the present invention, the initial surface roughness is consistent with the surface roughness in the usage process of the substrate, so as to solve the problem that the initial grinding rate is unstable, thereby significantly improving the stability of the substrate in the CMP process.

Owner:CHENGDU TIMES LIVE SCI & TECH

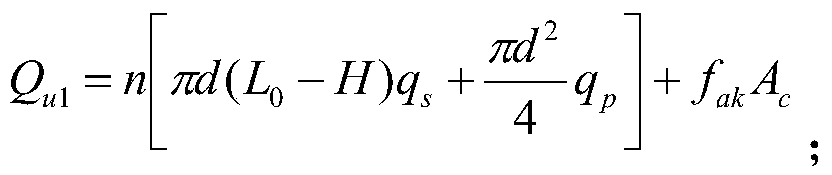

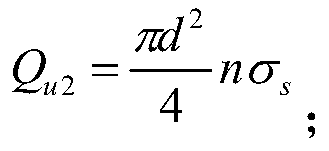

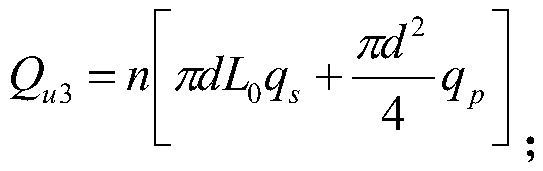

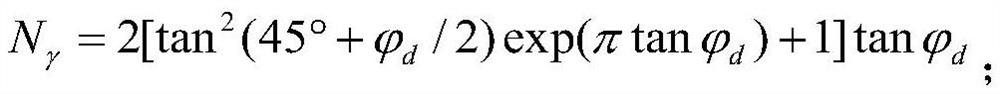

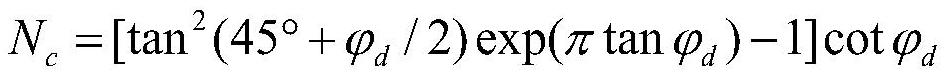

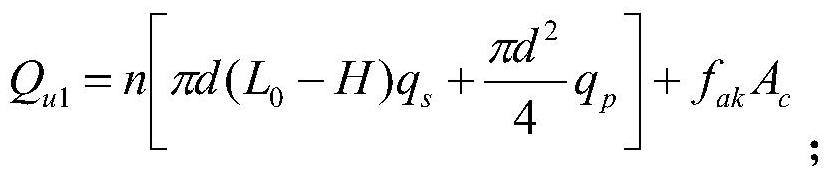

Method for predicting vertical bearing capacity of vertical reinforcement of karst soil cavity

ActiveCN110106854APredicted vertical bearing capacitySimple structureFoundation testingIn situ soil foundationKarstCompressive strength

The invention relates to a method for predicting the vertical bearing capacity of a vertical reinforcement of a karst soil cavity. The method comprises the following steps that the geometric dimensions such as length L, width W and height H and the soil covering depth of the karst soil cavity are determined; the number n, depth L<0> and diameter d of grouting holes of the karst soil cavity are determined; the compressive strength sigma<s>, the ultimate side friction q<s> and the ultimate end resistance q of the vertical reinforcement are determined; a characteristic value f<ak> of the foundation bearing capacity of a soil body at the bottom of the soil cavity is determined; a net area A<c> of the bottom surface of an enlarged body is determined; the ultimate bearing capacity Q<u1> jointly determined by a cylinder and the enlarged body is determined; the ultimate bearing capacity Q<u2> determined by the compressive strength of the cylinder is determined; the ultimate bearing capacityQ<u3> determined only by the cylinder is determined; the vertical ultimate bearing capacity Q of the vertical reinforcement is determined; and the vertical design bearing capacity R of the vertical reinforcement is determined. The method for predicting the vertical bearing capacity of the vertical reinforcement of the karst soil cavity has the advantages of simple structure, high process performance and reliable result, and can predict the vertical bearing capacity of the vertical reinforcement of the karst soil cavity more reliably.

Owner:福建惠丰建筑工程有限公司

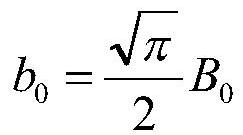

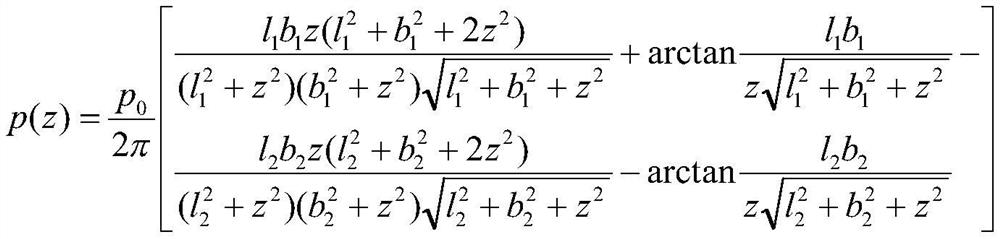

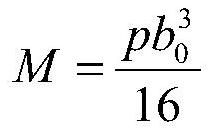

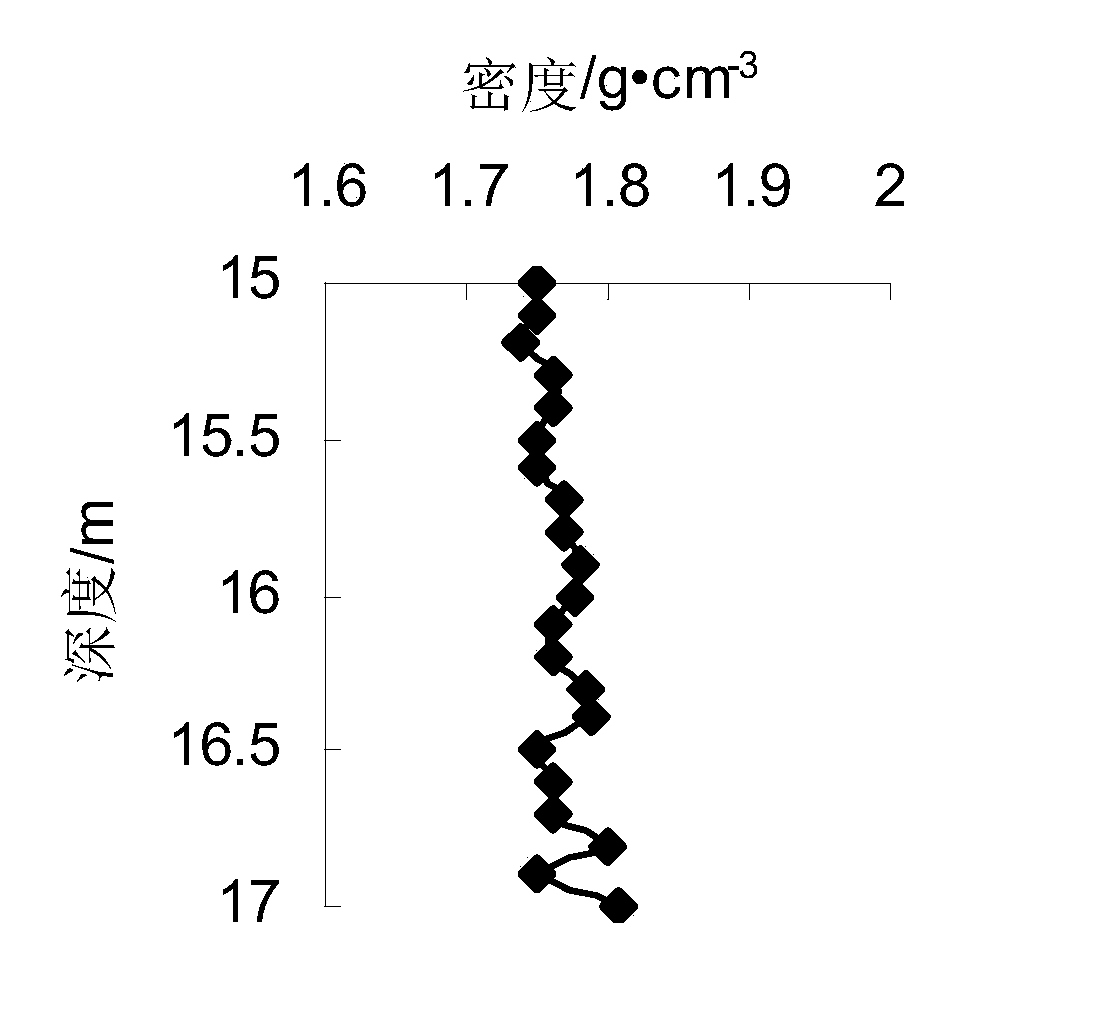

Method for predicting influence of construction of pipe-jacking tunneling machine on safety of overlying pipeline

The invention discloses a method for predicting the influence of construction of a pipe-jacking tunneling machine on the safety of an overlying pipeline. The method comprises the following steps of: firstly, sequentially determining the equivalent width b0 of a cutterhead of the tunneling machine and a horizontal additional stress expression p (z) generated by the cutterhead of the tunneling machine when the cutterhead of the tunneling machine cuts a soil body according to the diameter B0 of the cutterhead of the pipe-jacking tunneling machine and the soil pressure p0 applied by the cutterhead of the tunneling machine when the cutterhead of the tunneling machine cuts the soil body; then, determining the allowable tensile strength [sigma t] of the pipeline material, the maximum tensile stress sigma t generated by the cutterhead of the heading machine to the pipeline and the maximum deformation delta generated by the cutterhead of the heading machine to the pipeline; and finally comparing [sigma t], sigma t and delta, and judging the safety influence of the cutterhead of the heading machine on the pipeline. By means of the method, the method for predicting the influence of construction of the pipe-jacking tunneling machine on the safety of the overlying pipeline is reliable in prediction effect and accurate in prediction result.

Owner:CHINA RAILWAY NO 9 GRP

Predicating method for sinking depth of explosive compaction rockfill

ActiveCN110306522APrediction is simpleStrong processIn situ soil foundationSoil preservationEngineeringInternal friction

The invention discloses a predicating method for the sinking depth of explosive compaction rockfill. The predicating method comprises the following steps: acquiring the mean equivalent grain sizes d50of block stones, acquiring the rockfill density [rho]<0>; acquiring the density rho, the cohesive force c and the internal friction angle of foundation soil at different depths, and calculating the density rho', the cohesive force c' and the internal friction force of the foundation soil subjected to explosive compaction, and calculating the sinking pressure f of the rockfill; calculating the sinking resistance pu of a foundation at different depths; and setting the depth zi, wherein the depth zi is positioned below an embedded explosive package, if the sinking pressure f of a part above thedepth zi is higher than the sinking resistance pu, f is larger than pu, and if the sinking pressure f of a part below the depth zi is not higher than the sinking resistance pu, f is smaller than or equal to pu, and the depth zi is the maximal sinking depth of the rockfill. The predicating method has the advantages as follows: the sinking depth of the explosive compaction treatment foundation rockfill can be predicated, the predicating is simple, the process is strong, and the result is reliable.

Owner:HUAQIAO UNIVERSITY

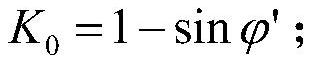

Method for predicting stability of tunnel grout-stopping wall under full-section grouting

ActiveCN114152284AStability PredictionStrong processMeasurement devicesHydro energy generationSoil scienceFriction angle

The invention relates to the field of infrastructure construction, in particular to a method for predicting the stability of a tunnel grouting-stopping wall under full-section grouting, which comprises the following steps: 1) measuring the vault elevation Z1 and the bottom elevation Z2 of a tunnel; (2) measuring and calculating the ground elevation Z3 of the water and mud bursting position of the tunnel, the mud surface elevation Z4 after water and mud bursting and the underground water level Z5; 3) acquiring characteristic data of the water-inrush and mud-inrush soft soil body below the underground water level: saturation weight gamma sat, effective weight gamma ', internal friction angle and static soil pressure coefficient K0; (4) the horizontal soil pressure sigma1x at the top face of the grout stopping wall, the horizontal soil pressure sigma2x at the bottom face of the grout stopping wall, the water pressure sigmaw1 at the top face of the grout stopping wall, the water pressure sigmaw2 at the bottom face of the grout stopping wall and the gravity G of the grout stopping wall are calculated; (5) the total horizontal thrust T borne by the grout stopping wall and the horizontal thrust resistance R of the grout stopping wall are calculated, and the stability of the grout stopping wall is judged according to R and T; if R is larger than or equal to T, it is judged that the grout stopping wall is in a stable state; and T, judging that the grout-stopping wall is in an unstable state.

Owner:FUJIAN UNIV OF TECH

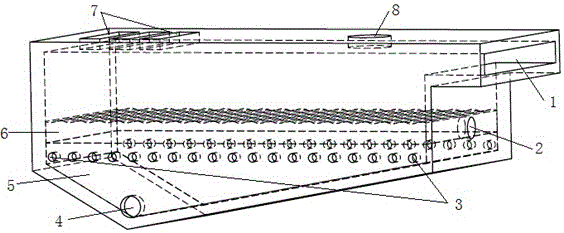

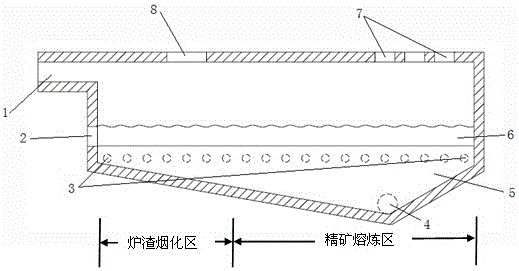

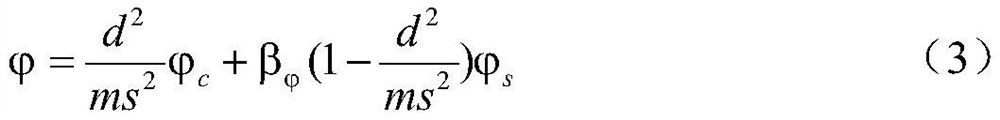

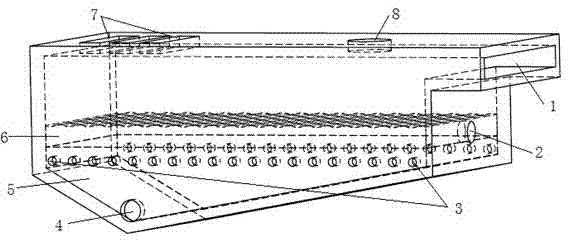

A wind-coal blowing furnace and a wind-coal blowing furnace smelting method for tin concentrate

Owner:KUNMING UNIV OF SCI & TECH

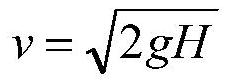

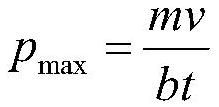

A method for predicting the safety of surrounding building pile foundations pulled down by blasting demolition of dangerous bridges

ActiveCN109898568BSimple structureStrong processFoundation testingArchitectural engineeringBridge deck

Owner:HUAQIAO UNIVERSITY

A Method for Predicting Subsidence Depth of Explosive Squeezing and Rock Filling

ActiveCN110306522BPrediction is simpleStrong processIn situ soil foundationSoil preservationTEX-explosiveFriction angle

The invention discloses a method for predicting the subsidence depth of rock filling by explosive squeezing silt, comprising: obtaining the average equivalent particle diameter d of rock filling 50 ; used to obtain the rockfill density ρ 0 ; Used to obtain the density ρ, cohesion c and internal friction angle of the foundation soil at different depths to calculate the density ρ', cohesion c' and internal friction angle of the foundation soil after the explosion squeezed silt; calculate the subsidence pressure of the rockfill f; Calculate the subsidence resistance p at different depths of the foundation u ;set depth z i , the depth z i Located below the buried explosive charge, if at the depth z i The above subsidence pressure f is greater than the subsidence resistance p u , ie f>p u , while at the depth z i The following subsidence pressure f is not greater than the subsidence resistance p u , that is, f≤p u , then the depth z i is the maximum subsidence depth of rockfill. It has the following advantages: it can predict the subsidence depth of the rockfill foundation treated by explosive silting, and the prediction is simple, the process is strong and the result is reliable.

Owner:HUAQIAO UNIVERSITY

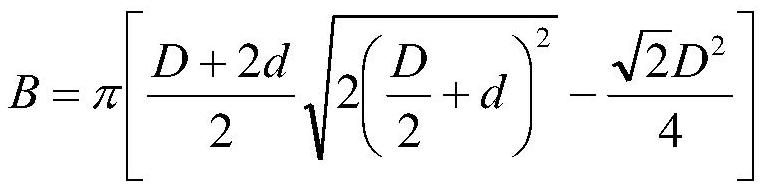

A Method for Predicting Hole Spacing of Horizontal High Pressure Grouting in Tunnel Mud Flushing Desilting

ActiveCN109855987BStrong processEasy to implementFlow propertiesMaterial strength using steady shearing forcesPorosityClassical mechanics

The invention relates to a hole position space prediction method for tunnel gushing mud desilting horizontal high-pressure grouting. The method comprises the following steps of determining the desilting gushing mud height H inside a tunnel and a slope angle alpha of a gushing mud slope surface; determining the cohesive force c<s>, the inner friction angle phi<s> and the weight r<s> of the tunnel desilting gushing mud; determining the cohesive force c<c>, the inner friction angle phi<c> and the weight r<c> of a high-pressure grouting body; determining the diffusion diameter d of the high-pressure grouting body; determining the integral normalized cohesive force c, the inner friction angle phi and the weight r of the grouting body and a gushing mud body after the high-pressure grouting; determining the unstability angle phi' after the grouting; and determining the hole position space s of the horizontal high-pressure grouting. The hole position space prediction method for the tunnel gushing mud desilting horizontal high-pressure grouting has the advantages that the flow process performance is high; the implementation is convenient; and the result is reliable.

Owner:HUAQIAO UNIVERSITY

Air coal blown converter and tin concentrate air coal blown converter smelting method

The invention relates to an air coal blown converter and a tin concentrate air coal blown converter smelting method and belongs to the technical field of non-ferrous metal pyrometallurgy. The air coal blown converter comprises a converter body, a flue, a slag hole, a tin discharging hole and a raw material inlet and also comprises an air coal blow pipe and a pyrite inlet, wherein the converter body is a cylinder, the bottom of the converter body is conical, the converter body is divided into a concentrate smelting region and a slag fuming region, the raw material inlet and the pyrite inlet are formed in the top of the converter body and respectively correspond to the concentrate smelting region and the slag fuming region. The tin concentrate air coal blown converter smelting method comprises the following steps: firstly adding tin concentrate and a reducing agent, optionally adding a solvent, and smelting in the concentrate smelting region and a reacting region to obtain crude tin and tin-containing slag, discharging the crude tin, then putting pyrite into the slag fuming region for carrying out fuming operation including volatilizing and collecting SnS smoke dust, and discharging low-tin slag. The tin concentrate air coal blown converter smelting method has the advantages of simple technology, short flow, safe and controllable process and good environmental benefit, and is easy to operate.

Owner:KUNMING UNIV OF SCI & TECH

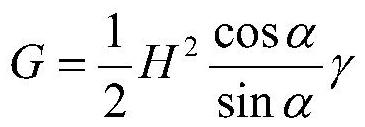

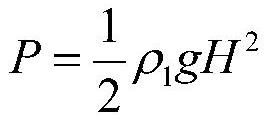

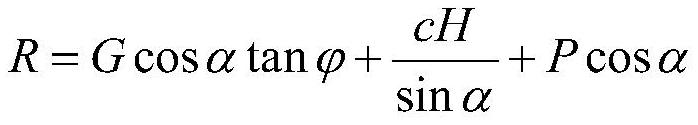

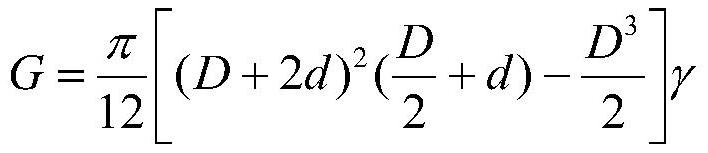

Method for predicting stability angle of offshore underwater high-pressure diluted sludge hole

ActiveCN112432882AStrong processEasy to useSurface/boundary effectForecastingMarine engineeringSludge

The invention provides a method for predicting a stability angle of an offshore underwater high-pressure diluted sludge hole. The method comprises the following steps: 1) determining cohesive force cand an internal friction angle of sludge; 2) determining a weight gamma of underwater sludge; 3) determining the depth H of the high-pressure diluted sludge hole; 4) determining the density rho1 of the slurry in the high-pressure diluted sludge hole; 5) incrementally valuing the angle alpha from 0.1 degree with 0.1 degree until the value reaches 89.9 degrees to form an angle sequence; 6) determining the weight G of an underwater unstable body within the unit width; 7) determining the pressure P generated by the sludge hole slurry on the hole wall within the unit width; 8) determining the resistance R of the underwater unstable body within the unit width; 9) determining the instability force T of the underwater unstable body in the unit width; and 10) drawing a curve B and a curve C by using Matlab software and taking the sequence a as an abscissa and the sequence r and the sequence t as an ordinate.

Owner:HUAQIAO UNIVERSITY

Method for predicting safety of pile body of hammered pile body in granite area

PendingCN114066012AReasonable designSafety predictionMeasurement devicesFoundation testingShear modulusSoil science

The invention relates to a method for predicting the safety of a hammered pile body in a granite area, which can predict the safety of the pile body in the granite area and prevent the pile body from being damaged, and is characterized by comprising the following steps of: firstly, determining the weight and the maximum stroke of a diesel hammer, and detecting the diameter and the top surface burial depth of a boulder by a geological radar or cross-hole earthquake CT method; determining the radius of the precast pile, the axial compressive strength design value of pile body concrete, the compressive bearing capacity limit value of the pile body, the elastic modulus and Poisson's ratio of granite residual soil, the shear modulus of the granite residual soil and the instantaneous maximum impact force borne by the top surface of the precast pile; then determining the soil body side frictional resistance borne by a pile body, determining the soil body side frictional resistance borne by the pile body, the dynamic cohesive force of granite residual soil and the weight of the granite residual soil, finally determining the resistance of the soil body at the lower part of the boulder, and judging whether the pile body is damaged or not by comparing the instantaneous maximum impact force with the resistance. The purpose of preventing the pile body from being damaged in advance is achieved.

Owner:FUJIAN UNIV OF TECH +1

A Prediction Method for Vertical Bearing Capacity of Vertical Reinforcement in Karst Cavern

ActiveCN110106854BPredicted vertical bearing capacitySimple structureFoundation testingIn situ soil foundationSoil scienceKarst

The invention relates to a method for predicting the vertical bearing capacity of a vertical reinforcement of a karst soil cavity. The method comprises the following steps that the geometric dimensions such as length L, width W and height H and the soil covering depth of the karst soil cavity are determined; the number n, depth L<0> and diameter d of grouting holes of the karst soil cavity are determined; the compressive strength sigma<s>, the ultimate side friction q<s> and the ultimate end resistance q of the vertical reinforcement are determined; a characteristic value f<ak> of the foundation bearing capacity of a soil body at the bottom of the soil cavity is determined; a net area A<c> of the bottom surface of an enlarged body is determined; the ultimate bearing capacity Q<u1> jointly determined by a cylinder and the enlarged body is determined; the ultimate bearing capacity Q<u2> determined by the compressive strength of the cylinder is determined; the ultimate bearing capacityQ<u3> determined only by the cylinder is determined; the vertical ultimate bearing capacity Q of the vertical reinforcement is determined; and the vertical design bearing capacity R of the vertical reinforcement is determined. The method for predicting the vertical bearing capacity of the vertical reinforcement of the karst soil cavity has the advantages of simple structure, high process performance and reliable result, and can predict the vertical bearing capacity of the vertical reinforcement of the karst soil cavity more reliably.

Owner:福建惠丰建筑工程有限公司

Method for determining number of nailed nails required for drawing on soil wall space

ActiveCN109623977AAccurately determineInhibit sheddingStapling toolsCovering/liningsProcess qualityGeomorphology

The invention provides a method for determining the number of nailed nails required for drawing on a soil wall space. The method comprises the steps that (1) hanging nets with an area of 1 m<2> are cut and obtained, the mass is weighed as m1, and then m1 is multiplied by gravity acceleration to obtain gravity G1; (2) the hanging net with a certain area is picked, the mass of the hanging net is divided by the volume of the hanging net to obtain the density rho1 of the hanging net with the certain area, and the thickness d1 of the hanging net with the certain area is determined by a vernier caliper; (3) a fresh attachment is picked, the density rho2 of the attachment is measured by a cutting-ring method, and the thickness z2 of application of the attachment is in the range of 0.5-1.0 cm; (4)the mass m2 of the attachment body after application to the soil wall space per unit area is determined; (5) the mass m3 of pigment per unit area is determined; and (6) the total gravity G of materials required for drawing on the soil wall space is determined. According to the technical scheme, high process quality, reliable results and other effects can be achieved by the method for determiningthe number of the nails.

Owner:HUAQIAO UNIVERSITY

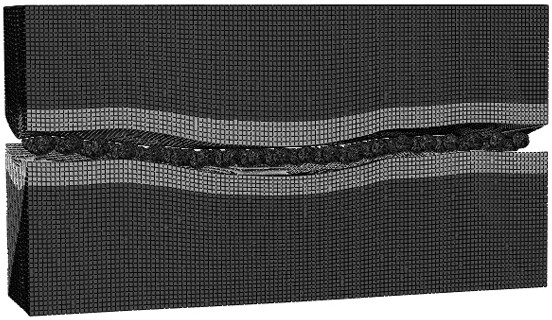

A numerical simulation method for quantitative prediction of proppant embedding and fracture conductivity

ActiveCN107423466BDisadvantages of Avoiding Contact BehaviorImprove accuracyData processing applicationsDesign optimisation/simulationPhysical modelEmbedment

The invention discloses a proppant embedment and fracture conductivity quantitative forecast-based numerical simulation method. The method comprises the following steps of: S1, establishing a physical model for reducing the real sizes of proppants; S2, applying closing pressure on the surfaces of an upper rock stratum and a lower rock stratum of the model, wherein the difference between average heights of granules on fracture surfaces of the upper rock stratum and the lower rock stratum is a fracture closing width w; S3, carrying out flow field grid dispersion on a filling layer to ensure that a flow field is wrapped by the proppants, setting viscosity and density of a fluid and pressure of the fluid at two ends of the flow field; S4, calculating a total flow q of the flow field; S5, calculating a permeability and a flow conductivity; and S6, changing physical parameters of the rock stratums or the fluid, and drawing a change curve graph indicating that the conductivity of the proppants with different sanding concentrations changes along with closing stress. The method has the beneficial effects of simulating the real processes of fracture closing, proppant embedment and interaction between granules and fluids, so as to effectively forecast the dynamic change of the flow conductivity.

Owner:SOUTHWEST PETROLEUM UNIV

A Method for Predicting the Formation Time of Surface Subsidence of Tunnel Water and Mud Inrush

ActiveCN109583047BEasy to useStrong processHydro energy generationDesign optimisation/simulationSoil scienceFriction angle

Owner:HUAQIAO UNIVERSITY

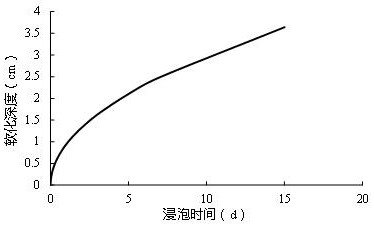

A calculation method for predicting proppant embedding depth considering shale softening

ActiveCN114547950BAccurate and Efficient PredictionImprove fitting abilityDesign optimisation/simulationSpecial data processing applicationsRock coreFinite element method

The invention relates to a calculation method for predicting the embedding depth of proppant considering the softening effect of shale. The self-absorption depth-soaking time curve was obtained; the standard cores under different soaking times were dried and then subjected to nano-indentation experiments on the surface respectively to obtain the Young's modulus-soaking time curve of the core surface; the softening layer was established by the finite element method. The proppant embedding model is obtained; numerical simulation is carried out to obtain the embedding amount-soaking time curve: the calculation formula of the proppant embedding amount considering the softening effect is obtained. The assumptions considered by the numerical model of the present invention are closer to reality, and the simulated and predicted fracture width values under different softening conditions have a high fit with the measured values, and at the same time have strong flowability, which can be used for actual shale reservoirs. Accurate and efficient prediction of fracture width after layer hydraulic fracturing.

Owner:SOUTHWEST PETROLEUM UNIV

Method for predicting safety of stratum boulders to overlying independent foundation in shield tunneling machine construction

PendingCN112819200AEnsure safetyStrong processForecastingDesign optimisation/simulationStructural engineeringShield tunneling

The invention discloses a method for predicting the safety of stratum boulders to an overlying independent foundation in shield tunneling machine construction, and the method comprises the following steps: comparing the destructive power of the boulders to a square independent foundation under the rotation action of a cutter head of a shield tunneling machine with the corresponding resistance under the destructive power; predicting and evaluating the influence of stratum boulders on the safety of the overlying square independent foundation in shield tunneling machine construction, so the safety of shield tunneling machine construction on surrounding structures is ensured; meanwhile, the method has the advantages of being high in process performance, reliable in result and convenient to use.

Owner:沧州交发工程项目管理有限责任公司

Method for predicting piling force when end part of precast pile encounters boulders

ActiveCN113378275AReasonable designReduce construction costsGeometric CADSpecial data processing applicationsSoil scienceStructural engineering

The invention relates to a method for predicting piling force when the end part of a precast pile encounters boulders. The method comprises the following parameters: the length and diameter of a piled pile; the diameter of the boulder; the dynamic cohesive force, the dynamic internal friction angle, the effective internal friction angle, the static soil pressure coefficient, the weight above the underground water level and the weight below the underground water level of the soil body around the pile; pile lengths above and below the underground water level; the average weight of the soil body in the pile length range according to the effective weight in depth; the resistance of soil around the pile to piling; the average vertical stress, the average horizontal stress and the average normal stress which are applied to the lower half part of the boulder; the average shear strength of the lower half part of the boulder; resistance of the lower half part of the boulder to piling; the average vertical stress and the average horizontal stress are applied to the upper half part; the average normal stress, the average shear strength and the resistance to piling of the upper half part of the boulder; and piling force when the end of the precast pile encounters boulders. The pile driving force needed when the end of the precast pile encounters boulders can be determined, the construction scheme is determined and adjusted in time, and use is convenient.

Owner:FUJIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com