A Method for Predicting Subsidence Depth of Explosive Squeezing and Rock Filling

A technology of depth prediction and explosion silting, which is applied in the field of infrastructure construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

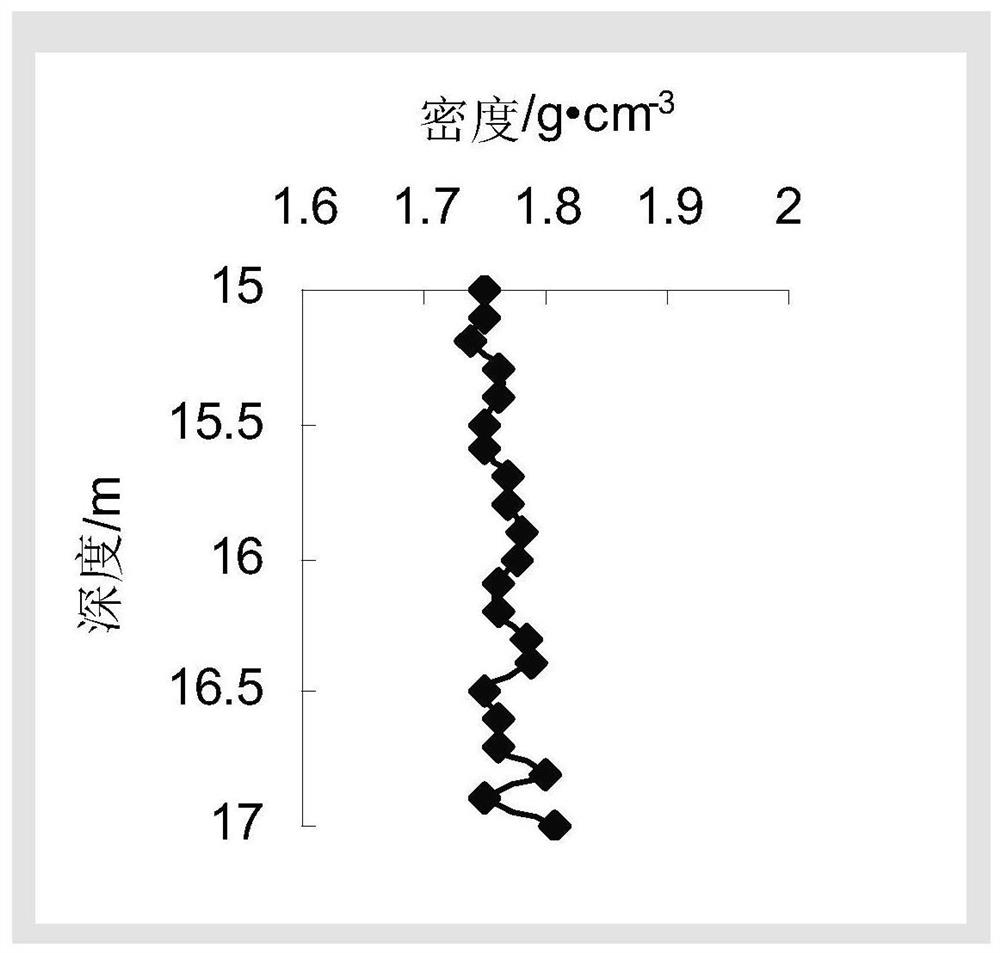

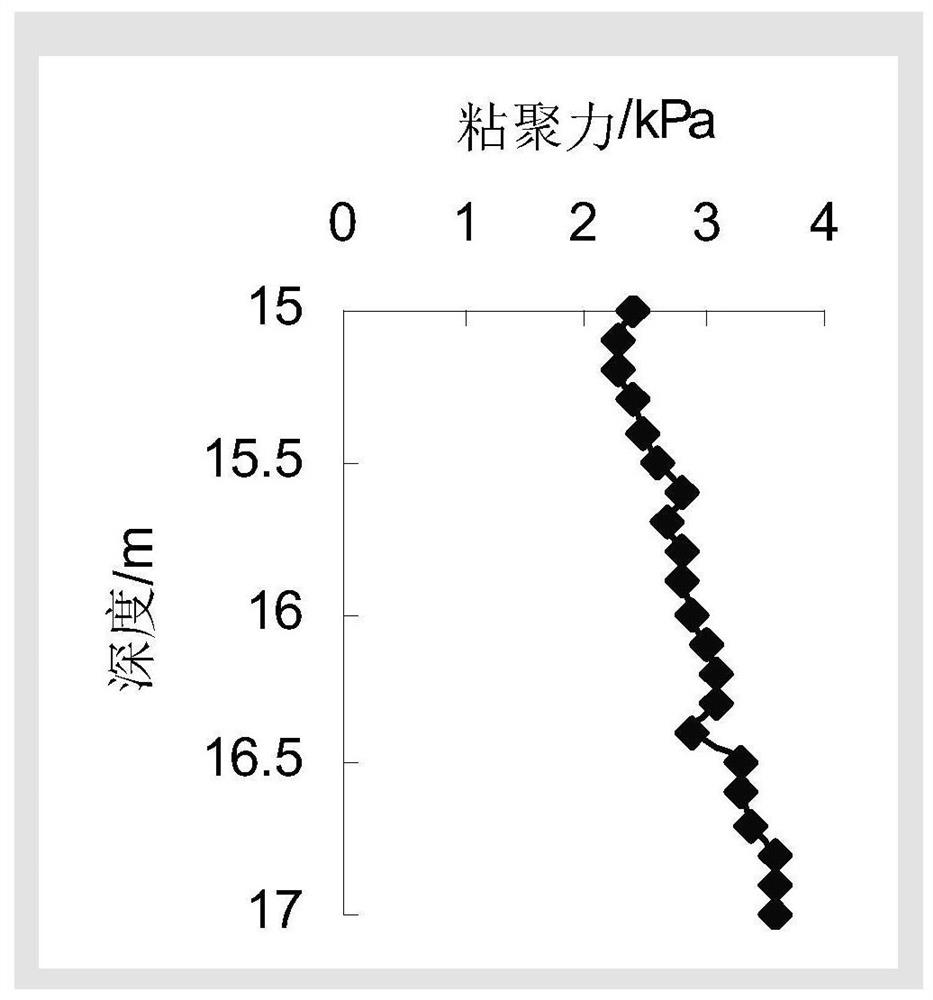

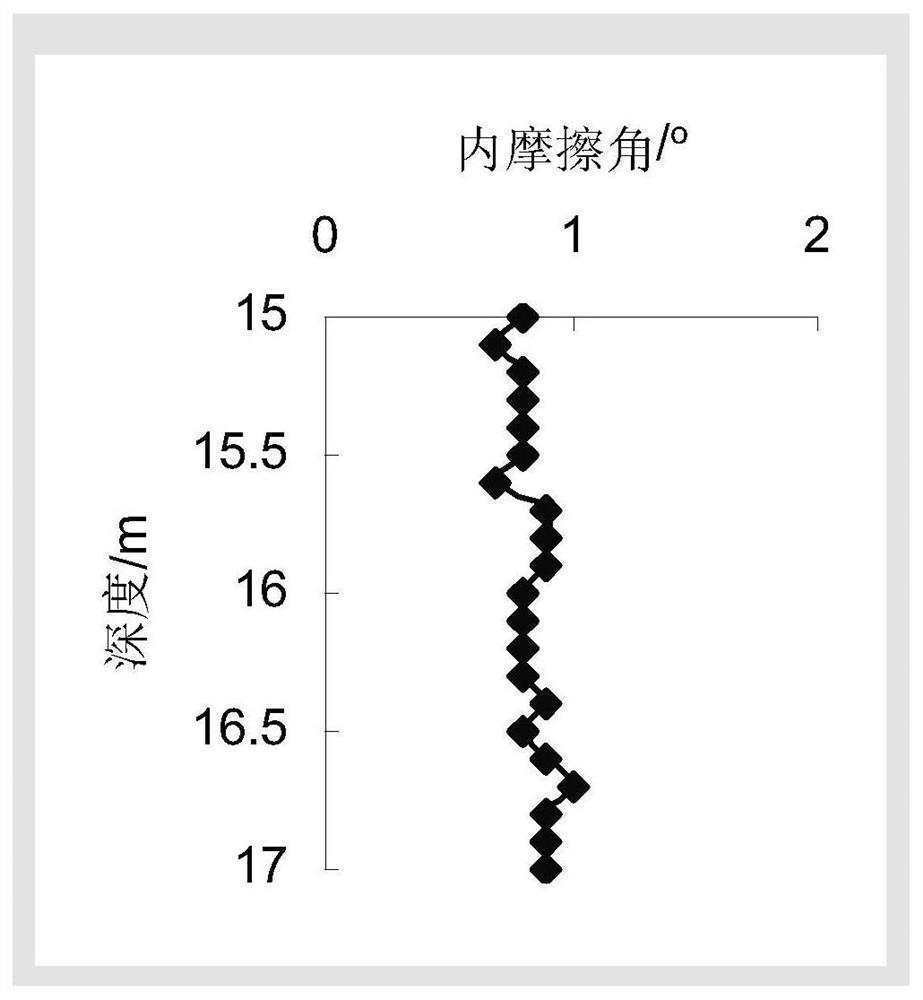

[0042] In the Luoyuan Bay embankment soft foundation treatment explosion silting project in Lianjiang County, Fuzhou City, Fujian Province, the embankment above the mud surface is 8m high and 9.4m wide at the top, adopting the structural type of slope embankment. The geological condition of the embankment is poor, and there is a silt layer up to 30m thick. 39m, silty clay, yellowish brown, with a small amount of sandy soil in the upper part; ④Below 39m, silty clay, mixed with gravel.

[0043] During the process of desilting by explosion, the explosives are laid at the head of the embankment, the width of the explosives is 42m, the average buried depth of the charges is 15m, the distance between the charges is 2m, and the weight of a single charge is 36kg.

[0044] Take 50kg of typical rockfill samples on site, conduct large-scale screening tests, and obtain the average equivalent particle size d of rockfill 50 is 0.21m; the density of the rockfill is tested to obtain its dens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com