Surface treatment process of CMP Polishing pad

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

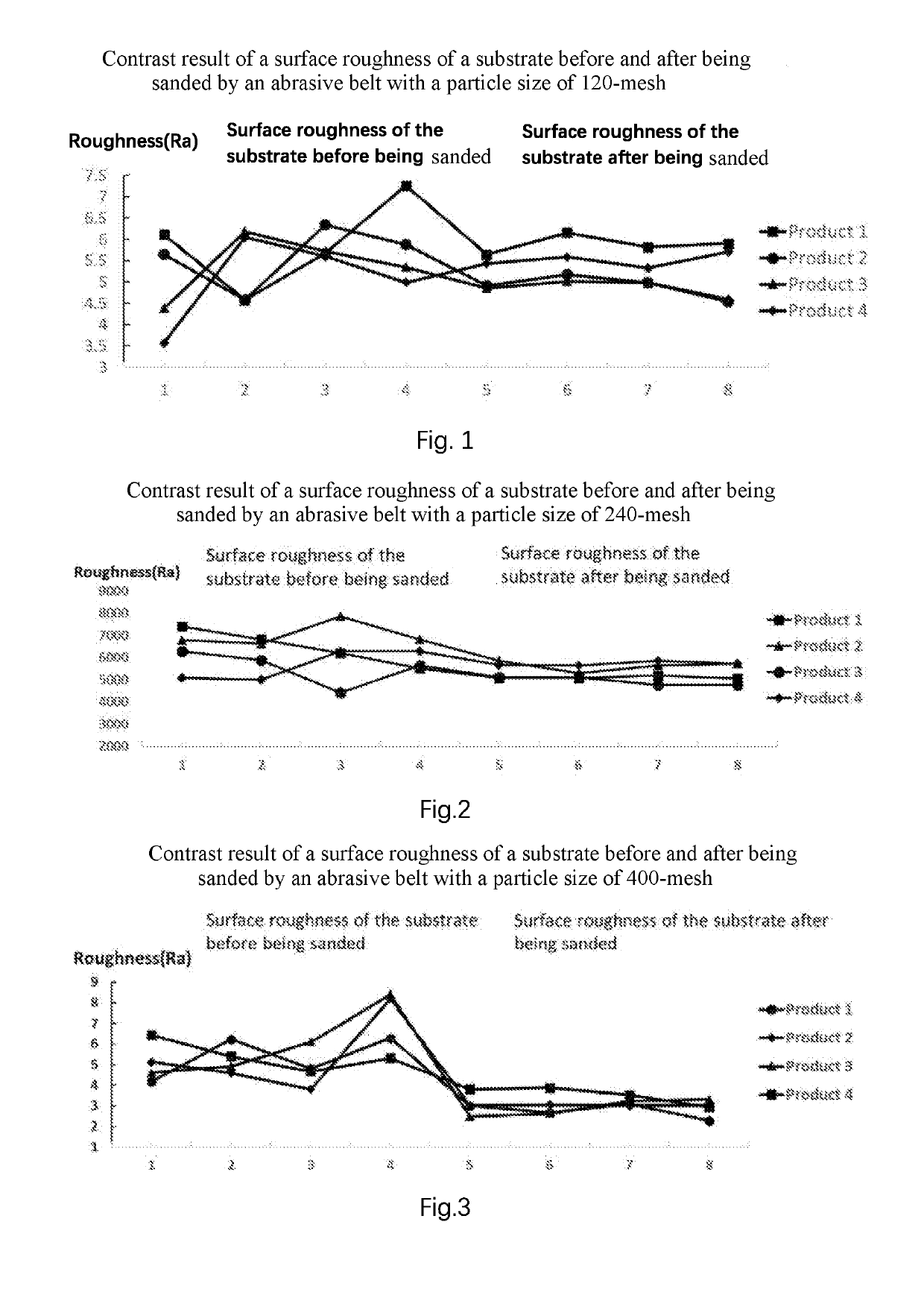

[0025]In the roughing process, a first abrasive belt with a particle size of 120-mesh and a substrate with a thickness of 2.65 mm are used, the substrate is placed in a sanding machine, a height of the first abrasive belt is adjusted to 2.56 mm, a front side of the substrate is sanded for a period of time and then the height of the first abrasive belt is adjusted to 2.47 mm, and then a reverse side of the substrate is sanded, and the thickness of the substrate is 2.47 mm measured by a vernier caliper.

[0026]In the fine process, a second abrasive belt with a particle size of 240-mesh is used, the above substrate is placed in the sanding machine, a height of the second abrasive belt is adjusted to 2.43 mm, the front side of the substrate is sanded for a period of time and then the height of the second abrasive belt is adjusted to 2.39 mm, and then the reverse side of the substrate is sanded, and the thickness of the substrate is 2.39 mm measured by the vernier caliper.

[0027]In the fini...

second embodiment

[0028]In the roughing process, a first abrasive belt with a particle size of 120-mesh and a substrate with a thickness of 2.65 mm are used, the substrate is placed in a sanding machine, a height of the first abrasive belt is adjusted to 2.56 mm, a front side of the substrate is sanded for a period of time and then the height of the first abrasive belt is adjusted to 2.47 mm, and then a reverse side of the substrate is sanded, and then the height of the first abrasive belt is adjusted to 2.39 mm, and then the front side of the substrate is sanded, and the thickness of the substrate is 2.39 mm measured by a vernier caliper.

[0029]In the fine process, a second abrasive belt with a particle size of 240-mesh is used, the above substrate is placed in a sanding machine, a height of the second abrasive belt is adjusted to 2.36 mm, the front side of the substrate is sanded for a period of time and then the height of the second abrasive belt is adjusted to 2.33 mm, and then the reverse side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com