Method for predicting stability angle of offshore underwater high-pressure diluted sludge hole

A prediction method and a technology of stable angle, applied in the field of infrastructure construction, can solve problems such as fish death, and achieve the effects of reliable results, strong process flow and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

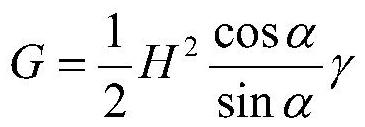

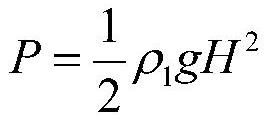

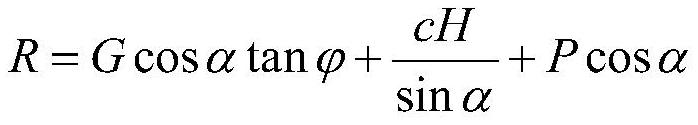

[0058]In an offshore bay in Fujian Province, the method of the invention was used to predict the stability angle of underwater high-pressure dilution silt holes. A typical silt undisturbed soil sample was taken from the silt foundation under seawater, sealed, and transported back to the geotechnical laboratory for non-solidification. Fast shear test to determine that the cohesive force c of the silt is 8kPa, and the internal friction angleIt is 7°; Use the remaining undisturbed soil sample mentioned above, use the ring knife method to carry out the density test, use the ring knife to test its volume, use a balance to weigh its mass, divide the mass by the volume to get its density, and then multiply it by the acceleration of gravity The weight γ is 16.5kN / m3;According to the design depth of sludge treatment in offshore waters, the depth H of the silt hole is determined to be 8m; according to experience, ρ1=1.20g / cm3; Using Matlab software, the angle α starts from 0.1° and takes the ...

Embodiment 2

[0060]A stone-filled breakwater was built in an offshore silt foundation in Fujian Province. The method of the invention was used to predict the stability angle of underwater high-pressure dilution silt holes. A typical undisturbed soil sample of the silt was taken from the offshore silt foundation, sealed and transported back. The geotechnical laboratory conducted an unconsolidated quick shear test and determined that the cohesive force c of the silt was 9kPa, and the internal friction angleIt is 6°; using the remaining undisturbed soil sample mentioned above, use the ring knife method to carry out the density test, use the ring knife to test its volume, use a balance to weigh its mass, divide the mass by the volume to get its density, and then multiply it by the acceleration of gravity The weight γ is 16.6kN / m3;According to the design depth of silt treatment in offshore water, the depth H of the silt hole is determined to be 12m; according to experience, ρ1=1.20g / cm3; Using Matlab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com