Method for predicting safety of pile body of hammered pile body in granite area

A prediction method and granite technology, applied in the field of infrastructure construction, can solve the problems that prefabricated piles cannot be smoothly driven to the design depth, the pile ends are driven directly above the boulders, and the pile body is damaged, and achieves reasonable design, reliable results, and high reliability. avoid damaging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific examples are given and described in detail as follows.

[0029] A method for predicting the safety of a hammer pile body in a granite area, comprising the following steps:

[0030] Step S1: determine the weight W and the maximum stroke H of the diesel hammer;

[0031] Step S2: Determine the diameter D of the boulder below the prefabricated pile body and the buried depth Z of the top surface;

[0032] Step S3: Determine the radius a of the prefabricated pile and the design value f of the axial compressive strength of the pile concrete c ;

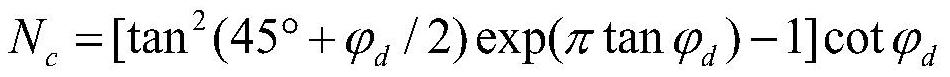

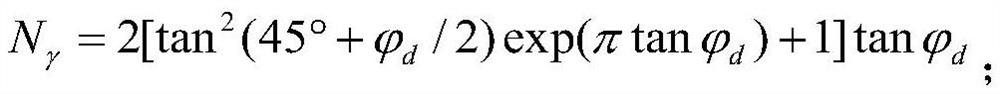

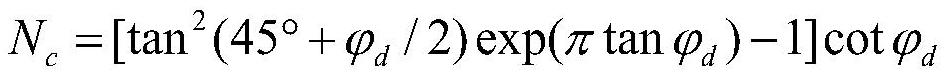

[0033] Step S4: Determine the limit value N of the compressive bearing capacity of the prefabricated pile body u , in, 0.85 is taken as the process coefficient for prefabricated piles; A p is the cross-sectional area of the prefabricated pile, A p = πa 2 ;

[0034] Step S5: Determine the elasti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com