Anti-thermal bridging exterior wall cladding panels

A covering board and effect technology, applied in the direction of covering/lining, building, building structure, etc., can solve the problems of thermal bridge effect, temperature rise, and reduce the thermal insulation performance of buildings, so as to maintain the flatness, improve the thermal insulation performance, The effect of avoiding heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

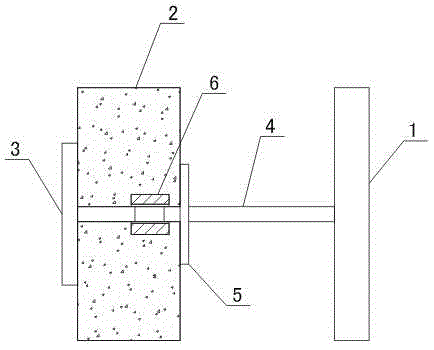

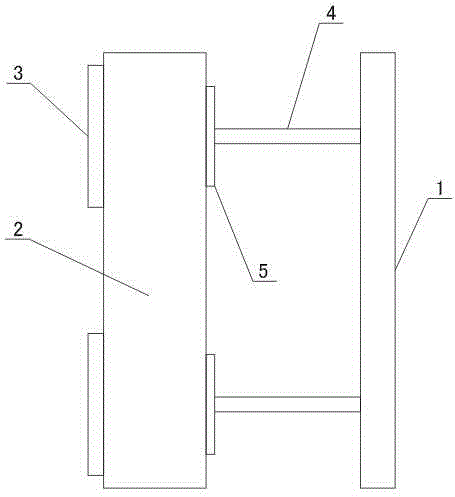

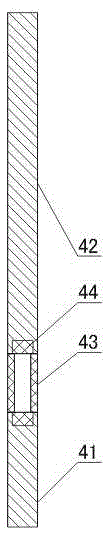

[0028] like Figure 1~Figure 3 As shown, the thermal bridge effect external wall covering board includes a fixed board 1, an insulation board 2, a decorative board 3 and a connecting body 4; the connecting body 4 includes a first section 41, a second section 42 and a middle section 43, and the middle section 43 It is a hollow pipe, and the two ends of the middle section 43 are provided with a small-diameter threaded section 44, and the rear end of the first section 41 and the front end of the second section 42 are provided with threaded holes, and the small-diameter threaded section 44 is connected with the first section 41 rear end respectively. It is threadedly connected with the front end of the second section 42, the rear end of the second section 42 is connected with the fixed plate 1, and the front end of the first section 41 runs through the insulation board 2 and is connected with the decorative panel 3; the first section 41 and the second section 42 are formed by Made...

Embodiment 2

[0032] like figure 1 As shown, this embodiment is based on Embodiment 1, and the middle section 43 is located inside the insulation board 2 .

[0033] Due to the low strength of plastics, in order to ensure the stability of the overall structure of the present invention, the middle section 43 is arranged inside the insulation board 2, so that the insulation board 2 and the middle section 43 bear the load together, thereby reducing the bearing force of the middle section 43 and preventing The middle section 43 is broken.

Embodiment 3

[0035] like figure 1 and figure 2 As shown, on the basis of Embodiment 2, the present embodiment is provided with external threads on the second section 42; it also includes a fixed disk 5 threadedly connected with the external threads on the second section 42, and the fixed disk 5 is close to the outer surface of the insulation board 2.

[0036] The fixed disk 5 is set, and the fixed disk 5 and the decorative board 3 clamp the insulation board 2 together to prevent the insulation board 2 from being displaced on the connecting body 4 after a long time of work, so that after the present invention is laid on the outer wall, the building can be effectively maintained. The flatness of the outside of the object.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com