Centralized exhaust system for large-sized pump station

A technology for exhaust systems and large-scale pumping stations, which is applied to pumps, drive pumps, pump devices, etc., and can solve problems such as large self-priming devices, production accidents, and grid connection difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

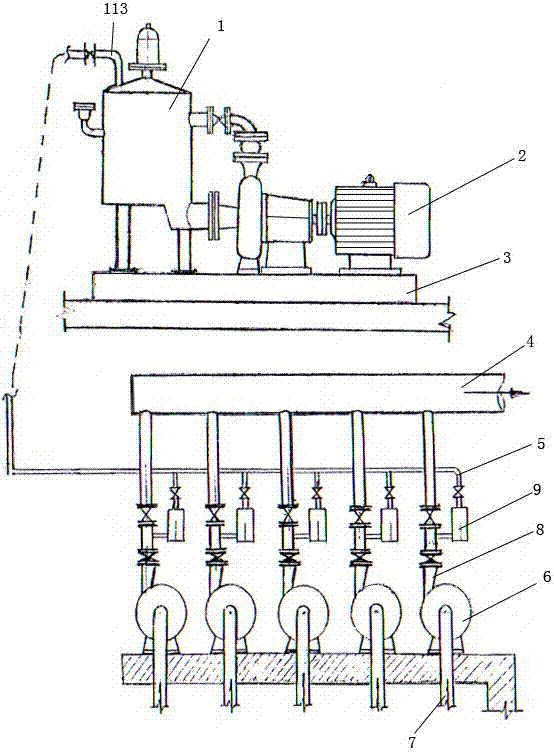

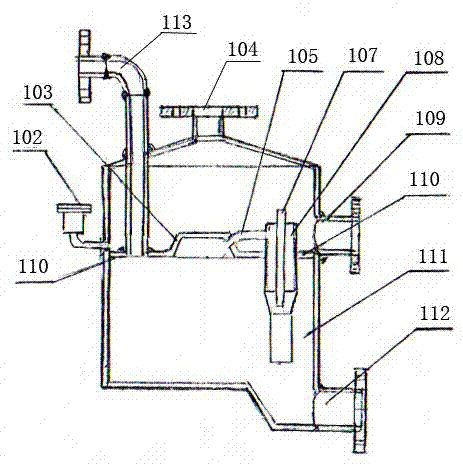

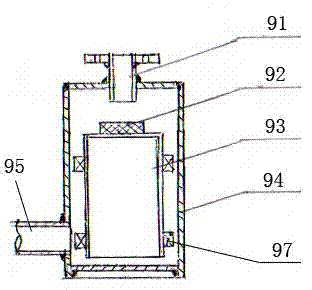

[0014] like figure 1 As shown, the centralized exhaust system of the large-scale pumping station of the present invention includes an updraft circulating air exhaust self-priming device 1, several centrifugal water pumps and several air exhaust water blockers 9, an upward suction circulating air exhaust self-priming device 1, a centrifugal water pump 2 is fixed on the mounting bracket 3. The water outlet pipe 112 of the updraft circulating exhaust self-priming device 1 is connected to the inlet of the centrifugal water pump 2 , and the outlet of the centrifugal water pump 2 is connected to the circulating water inlet pipe 109 . Each exhaust water blocker 9 is connected with a centrifugal water pump 6, the outlet pipe 8 of the centrifugal water pump 6 is connected with the main water delivery pipe 4 of the pump house, and one port of the air exhaust water blocker 9 is connected with the outlet pipe 8 on the casing of the centrifugal water pump 6 The other port of the exhaust w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com