A superposition sequence valve

A sequence valve, superimposed technology, applied in the direction of valve details, multi-way valves, valve devices, etc., can solve the problems of high cost, complex sequence valve structure, large control deviation, etc., to achieve low cost, simple structure, small control deviation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical scheme of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

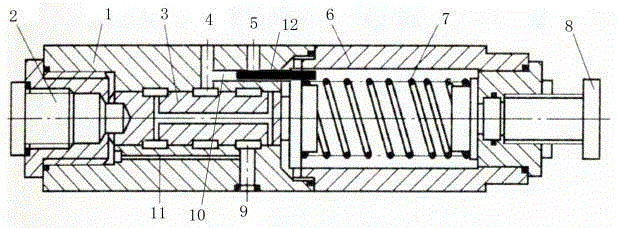

[0015] Such as figure 1 As shown, a stacked sequence valve includes a valve body 1 with a certain thickness, a valve core 3 is arranged in the valve body 1, and a pressure detection port 2 is arranged on one side of the valve body 1 (the left side in the figure). The other side of the valve body 1 (the right side in the figure) is provided with a spring 7, and the tail of the spring 7, that is, the right side of the spring 7, is provided with an adjusting screw 8. The spring 7 force of the spring 7 can be adjusted by adjusting the screw 8, thereby controlling The status of each outlet. The spring 7 is arranged on one side of the valve body 1 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com