High-intensity quick-disassembly fastener for airplane covering cap

A high-strength, flap-cap technology, applied in the direction of threaded fasteners, locking fasteners, connecting components, etc., can solve the problems of failure of double-threaded bolt components, the inability of the aircraft to take off quickly, and the inability to achieve rapid installation. Fast unlocking, high shear strength, and the effect of avoiding failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0038] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS The present invention is described in detail below according to the accompanying drawings:

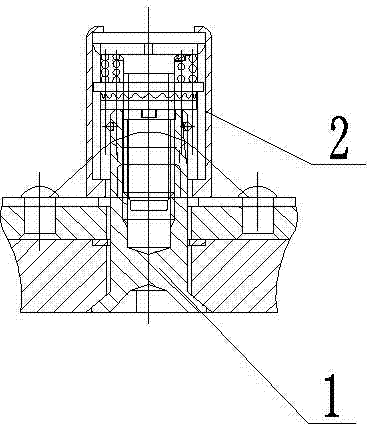

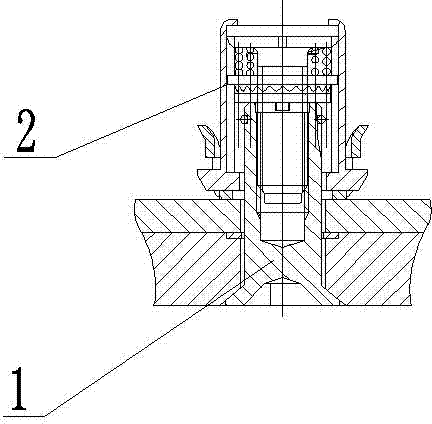

[0039] Such as figure 1 , 2 As shown, a high-strength quick-release fastener for an aircraft cover is composed of a cylindrical nut assembly 1 with four-wire internal threads and a double-lug floating seat assembly 2 with four-wire external threads.

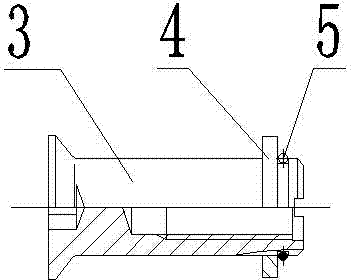

[0040] Such as image 3 , 4 As shown, the cylindrical nut assembly 1 with four-wire internal thread is composed of a four-wire thread cylindrical nut 3, a washer 4 and a retaining ring 5. When in use, the four-wire thread cylindrical nut 3 is passed through the hole of the upper sandwich plate, and then Put the washer 4 and the circlip 5 on the other side to prevent the four-wire threaded cylindrical nut 3 from falling off the upper sandwich plate.

[0041] Such as Figure 5 , 6 As shown, the double lug swimming base assembly 2 with four-wire external thread is composed of a b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com