Baffle plate type noise reduction gear

A baffle type, gear technology, applied to the baffle type noise reduction gear. In the field, it can solve the problems of high gear noise, etc., and achieve the effect of meeting production needs and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

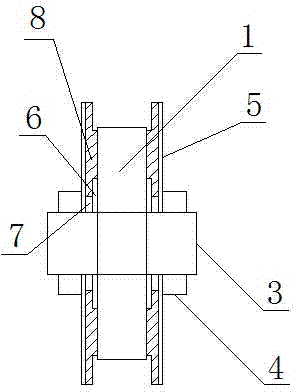

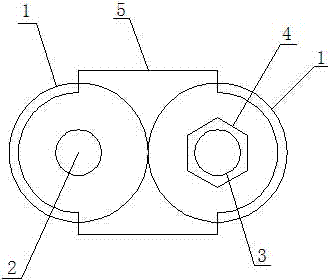

[0012] Such as figure 1 It is a structural schematic diagram of the present invention, a baffle type noise reduction gear, including a gear 1 and a gear shaft 3, the gear 1 is installed on the gear shaft 3, and baffles 5 are arranged on both sides of the gear 1, and the baffle The plate 5 is provided with a through hole 2, and the through hole 2 is sleeved on the gear shaft 3, and the gear shaft 3 is provided with a tightening nut 4, and the upper inner side of the baffle plate 5 is provided with a sound-absorbing layer 8.

[0013] According to another embodiment of the present invention, it further includes that the two sides of the gear 1 are provided with stoppers 6 .

[0014] According to another embodiment of the present invention, it further includes that a spacer 7 is provided at the center of the stopper 5 .

[0015] This baffle-type noise reduction gear covers the gear shaft 3 of the gear 1 with a baffle 5, processes a stopper 6 at the inner circle of the gear 1, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com