Water mixing device

A technology of water mixing and water end, which is applied in the direction of valve device, valve operation/release device, valve details, etc. It can solve the problems of inconvenient installation and use on site, increase of overall length and volume, increase of sealing points, etc., and reduce pipe fittings Amount and volume, easy installation and maintenance, reduce the effect of connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

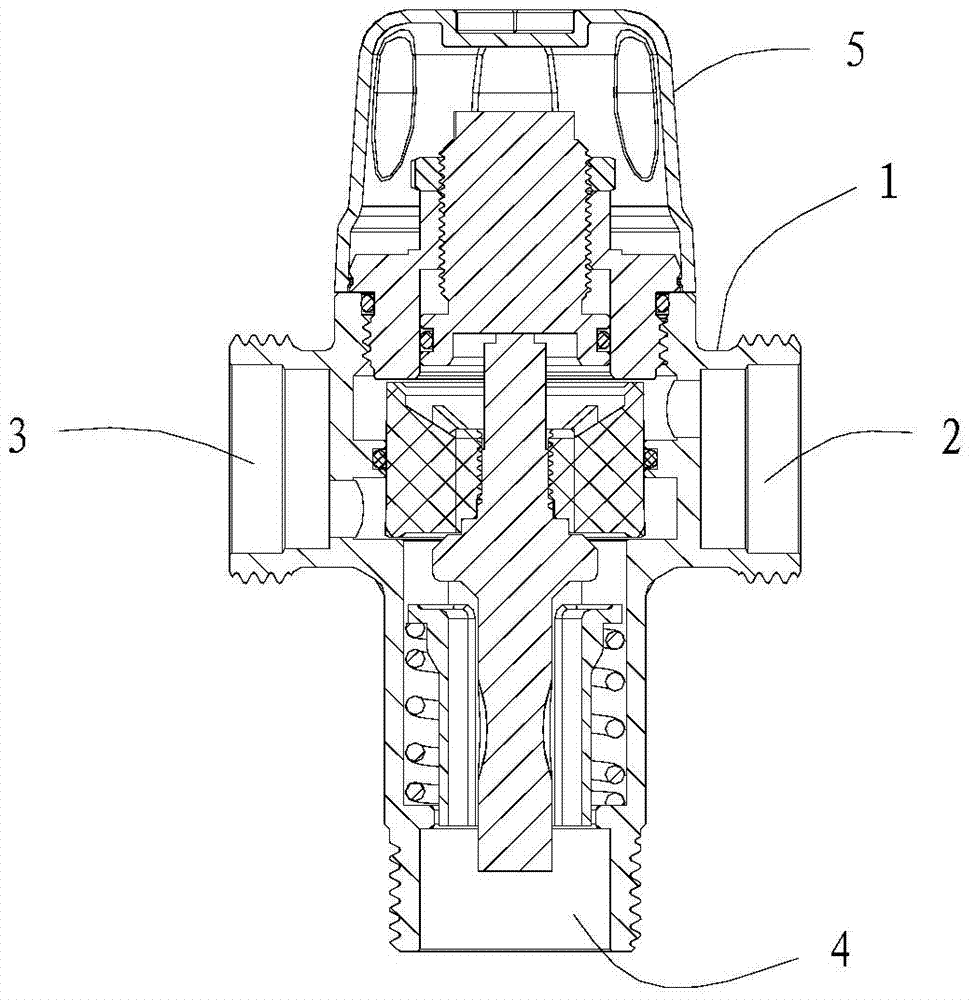

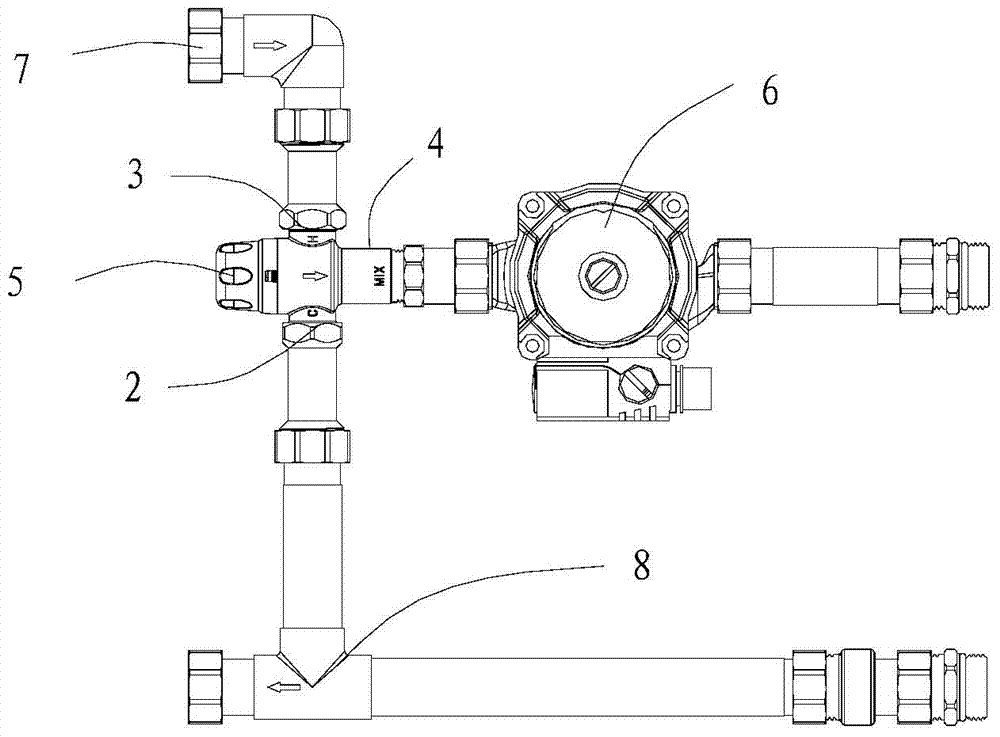

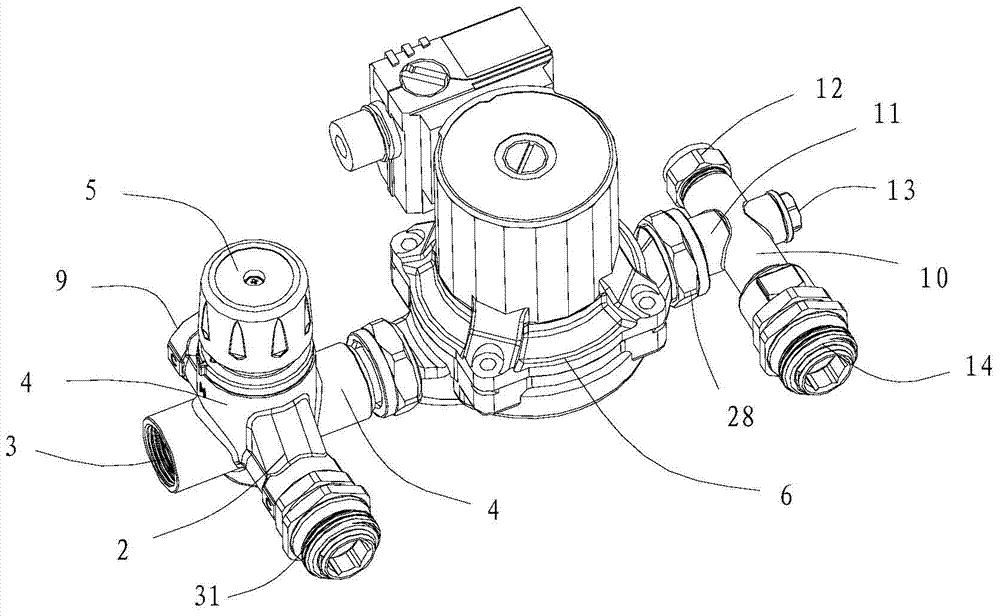

[0029] refer to Figure 3-12 , a water mixing device, including a thermostatic mixing valve body 1 with an adjustment handle 5, a return water end 2, an inlet water end 3, a mixing water end 4, a second water return end 9, and a circulating pump 6, wherein the second The return water end 9 is located on the same plane as the return water end 2, the water inlet end 3 and the mixing water end 4. The adjustment handle 5 is vertically arranged on the valve body 1, and the outlet of the circulation pump 6 is provided with a water diversion cross 10, and the water diversion The four-way 10 is provided with a first port 11 connected to the outlet of the circulation pump 6 , a second port 12 connected to the bypass interface, a third port 13 connected to the exhaust valve and a fourth port 14 connected to the inlet of the water separator.

[0030] The valve body 1 of the thermostatic water mixing valve is a four-way structure, and its four ports are located on the same plane, which ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com