Method for Measuring Air Specific Heat Capacity Ratio by Piston Vibration in Single-End Sealed Vertical Cylinder

A technology of specific heat capacity ratio and inner piston, which is used in measuring devices, instruments, scientific instruments, etc., can solve the problems of difficulty in realization, rotational uncertainty, lack of simple harmonic vibration, etc., and achieves the effect of simple structure and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

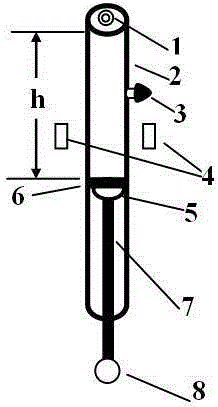

[0013] A cylinder 2, whose internal radius is r, is made of hard transparent materials, such as glass and hard plastic, which can withstand pressure and have relatively small (negligible) deformation caused by pressure. The cylinder 2. The upper end is sealed. The outer upper end plane of the cylinder 2 is perpendicular to the axis of the cylinder 2; The cylinder 2 is fixed on a support, and the fixed support adopts the tripod support frame of the prior art, that is, there are three feet for adjusting the level at the bottom. By adjusting the vertical height of the three feet, the upper end of the outside of the cylinder 2 is in the plane The horizontal bubble 1 shows that the end face is in a horizontal state, and the cylinder 2 is in a vertical state.

[0014] There is a sealing piston 6 inside the cylinder 2, and a metal hemisphere 5 is fixed at the lower end of the piston 6, which can be fixed by means of through holes, screws, nuts, sealing washers in the prior art, or ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com