Stereoscopic display unit and production method thereof

A stereoscopic display device and display control technology, applied in stereoscopic systems, optics, instruments, etc., can solve the problems of resolution sacrifice, uneven brightness distribution, moiré, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

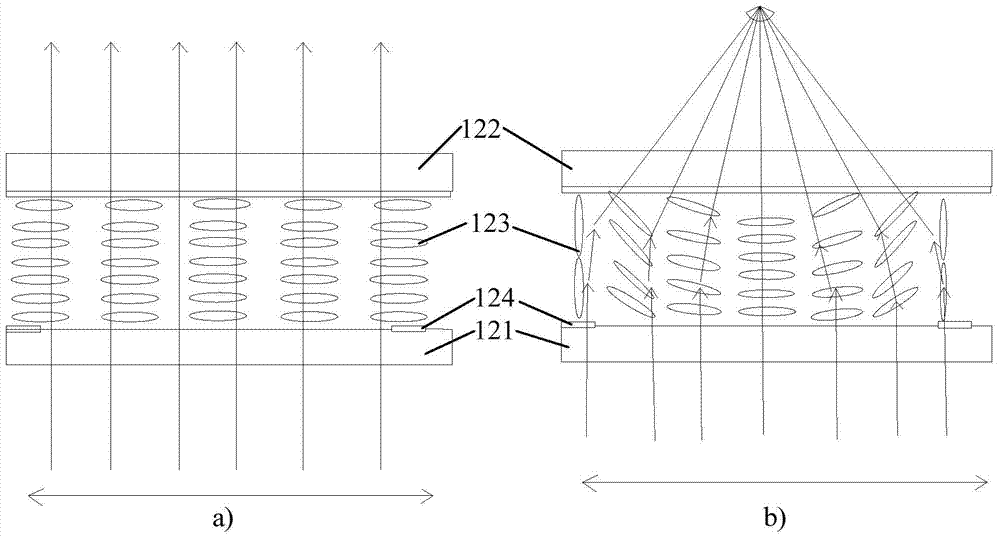

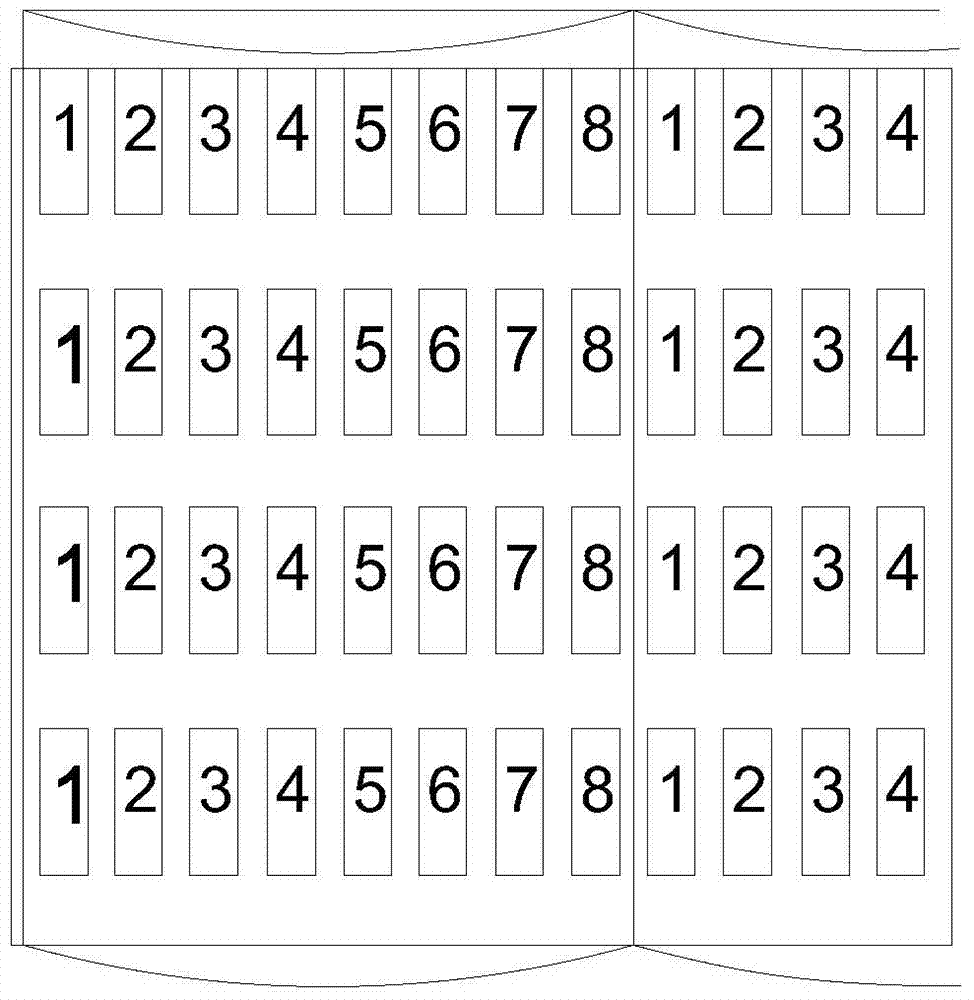

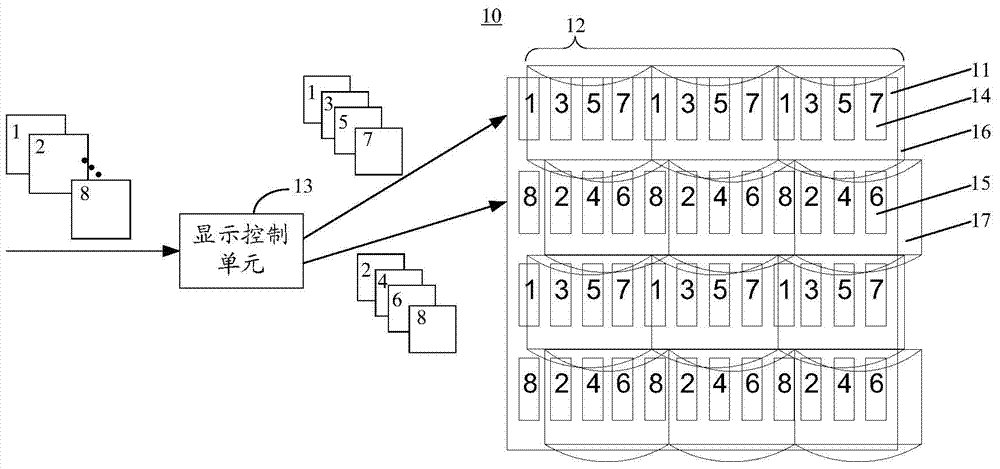

[0031] see figure 2 , figure 2 is a schematic structural view of the stereoscopic display device according to the first embodiment of the present invention. Such as figure 2 As shown, the stereoscopic display device 10 includes a display panel 11 , a grating lens 12 and a display control unit 13 . The display panel 11 includes a first row of sub-pixels 14 and a second row of sub-pixels 15 arranged adjacently along the column direction. The first row of sub-pixels 14 and the second row of sub-pixels 15 respectively include a plurality of sub-pixels arranged periodically along the row direction. The display control unit 13 acquires a plurality of viewpoint images, and divides the plurality of viewpoint images into a first group of viewpoint images and a second group of viewpoint images. The display control unit 13 further controls the first row of sub-pixels 14 to periodically display the content of each viewpoint image in the first group of viewpoint images, and controls...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com