Screening device

A screening device and plastic granule technology, applied in sorting and other directions, can solve the problems of low accuracy, waste of human resources, low efficiency, etc., and achieve the effect of improving accuracy and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

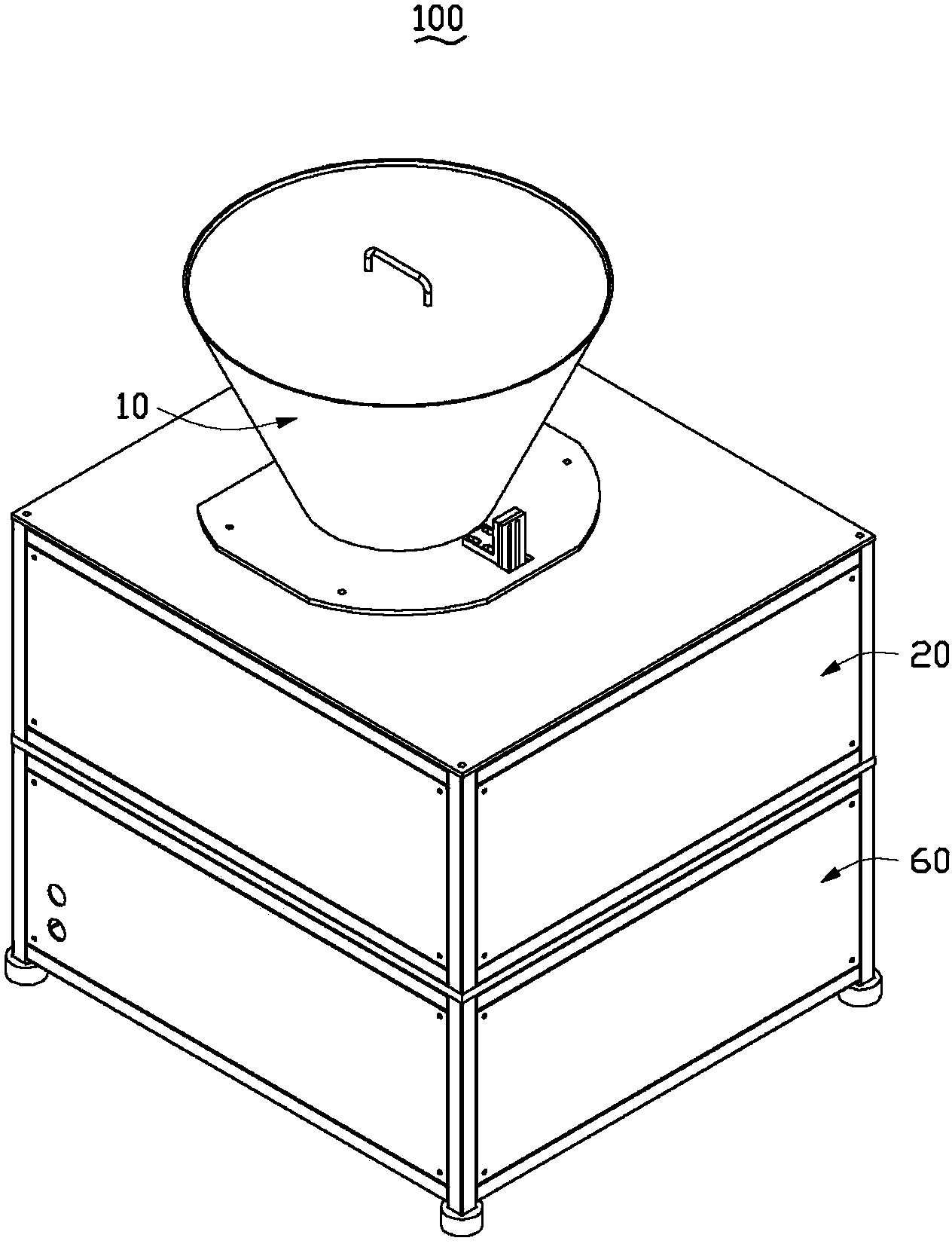

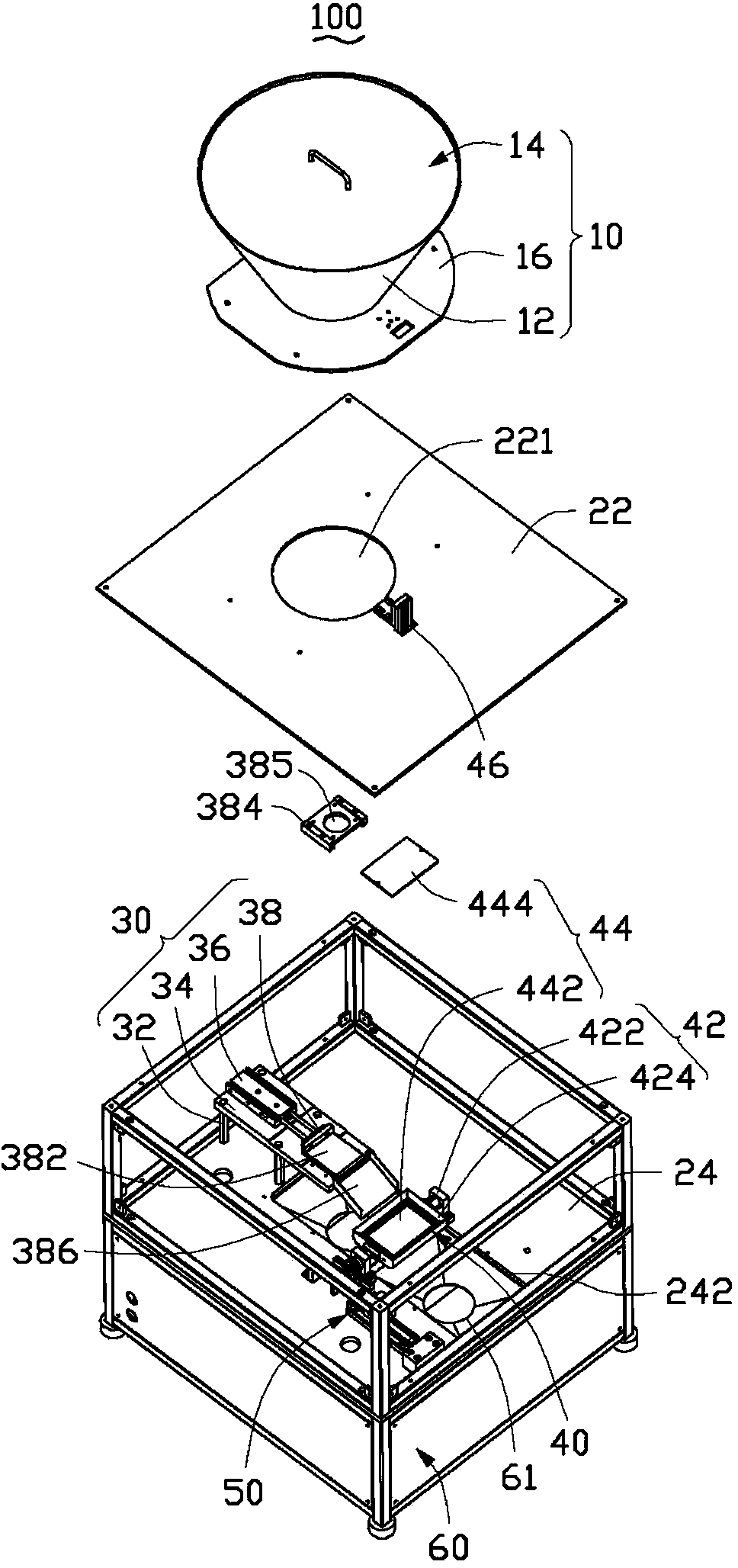

[0057] see figure 1 and figure 2 , the screening device 100 of the preferred embodiment of the present invention is used to screen out the plastic pellets of different colors from the plastic pellets to be detected. The component 40 , the transmission component 50 and the second box 60 . The first box body 20 supports the discharging assembly 10, the pushing assembly 30, the detection assembly 40 and the transmission assembly 50 are accommodated in the first box body 20, and the second box body 60 is located below the first box body 20 and connected to the first box body 20 .

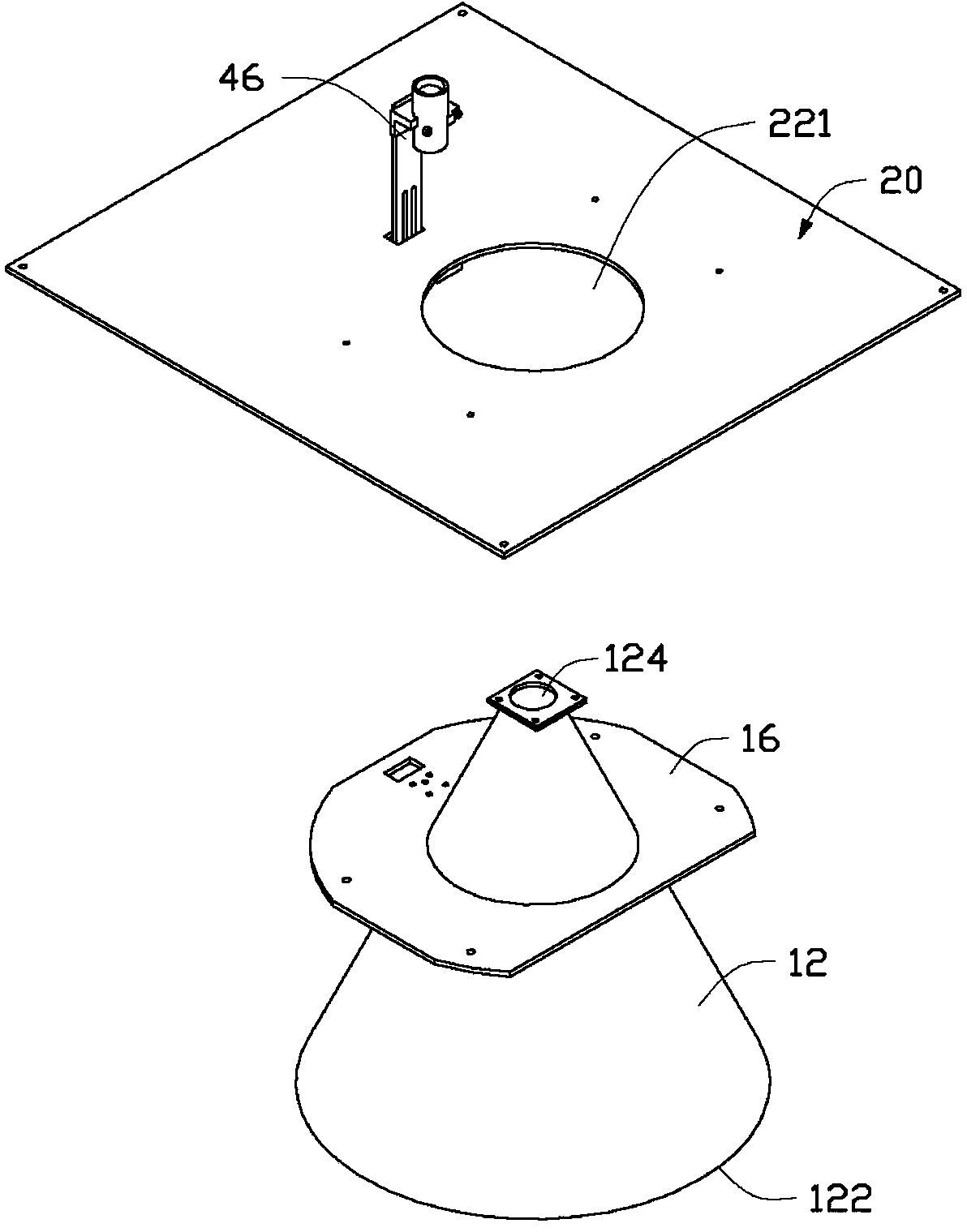

[0058] The discharging assembly 10 includes a discharging funnel 12 , a cover 14 covering the discharging funnel, and a fixing plate 16 engaged with the discharging funnel 12 . see image 3 , the discharge funnel 12 is an inverted conical structure, with a feed opening 122 at one end and a discharge opening 124 at the other end. The size of the material inlet 122 is larger than that of the materia...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap