Diaphragm wall protection layer plate

A technology of protective layer and ground-connected wall, applied in sheet pile wall, construction, infrastructure engineering, etc., can solve the problems of slow corrosion rate of steel bar 5, threat to the safety of ground-connected wall structure, etc. The effect of safety and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

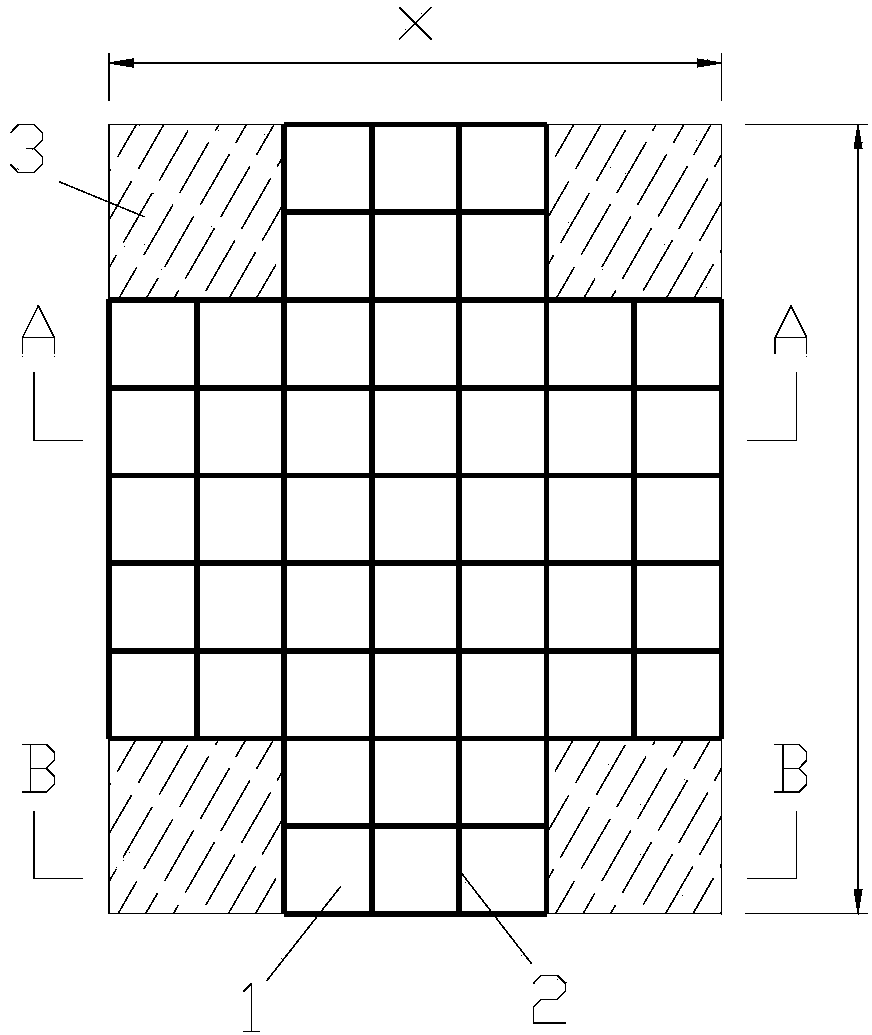

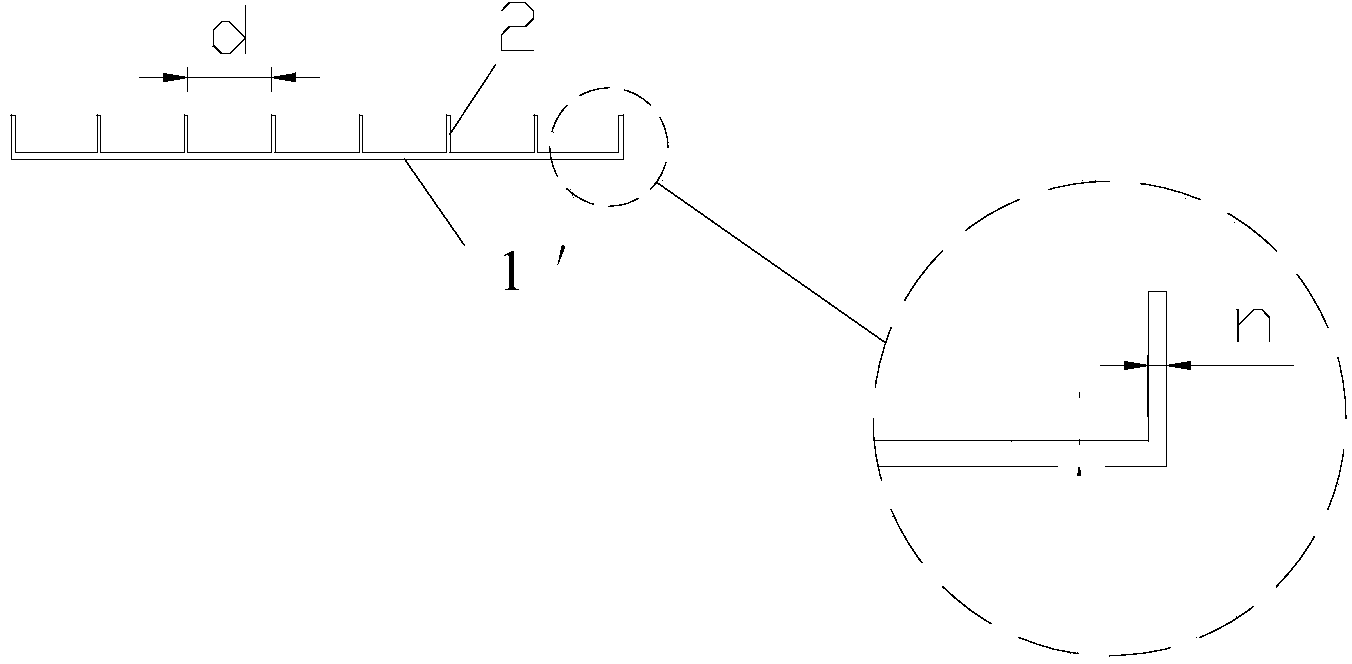

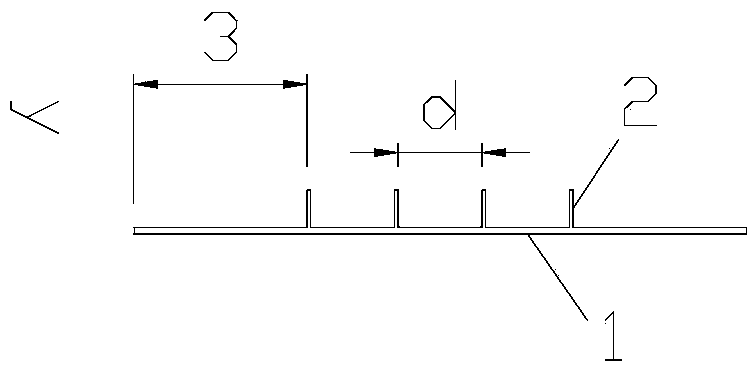

[0020] The structure and use of the ground-connected wall protective laminate of the present invention will be further described below in conjunction with the accompanying drawings.

[0021] The design idea of the ground connection wall protective layer plate of the present invention is to learn from the construction method of the steel bar erecting formwork in the reinforced concrete structure on the ground, and to add a protective layer outside the ground connection wall reinforcement cage as a whole, which solves the problem of adverse geological conditions on the ground connection wall. The negative impact of construction ensures the thickness of the ground connection wall and the quality of the wall. Especially in the excavation of the foundation pit, including the dredging side of the harbor basin, it effectively blocks the intervention of substances that can promote the corrosion of steel bars, such as air and water, and further ensures the reliability and durability o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com