Gas extraction drill hole plugging method and device

A gas extraction and plugging device technology, applied in gas discharge, safety devices, mining equipment and other directions, can solve the problems of waste grouting pipe, difficult transportation of viscous slurry, failure of sealing holes, etc., to achieve strong adaptability and reliability. Good sealing and expansion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

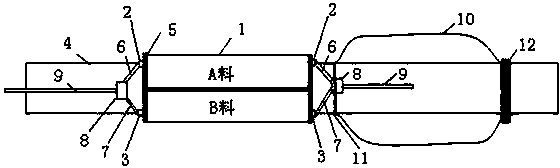

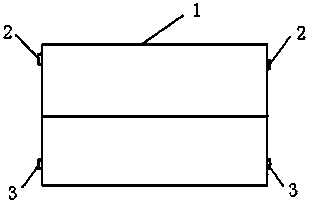

[0013] Such as figure 1 , figure 2 As shown, the plugging device of the present invention includes a soft bag 1, in which polyurethane material A and material B are isolated, and the two sides of the material A and material B of the soft bag 1 are respectively provided with a hole-sealing bag joint 2 , 3. The two ends of soft bag 1 are wound on the outer wall of gas extraction pipe 4, and it is fixed with adhesive tape 5 (the connection position is also fixed in the figure). Connect a nylon tube 6, 7 to the sealing bag joints 2, 3 on both sides of material A and material B respectively, and connect the two nylon tubes 6, 7 on the same side to one interface of the same tee 8, The third interface of each tee 8 is connected with an air pipe 9 . Put the ventilation pipe 9 on one side into an elastic bag 10, then wrap the elastic bag 10 on the outer w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com