Device capable of evaluating dynamic sand-carrying capacity of foam fracturing fluid and working method of device

A foam fracturing fluid and evaluation device technology, applied in the direction of measuring devices, flow characteristics, instruments, etc., can solve the problems of high cost, difficulty in popularization, and bulky volume, and achieve strong pressure resistance, easy popularization, and high reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

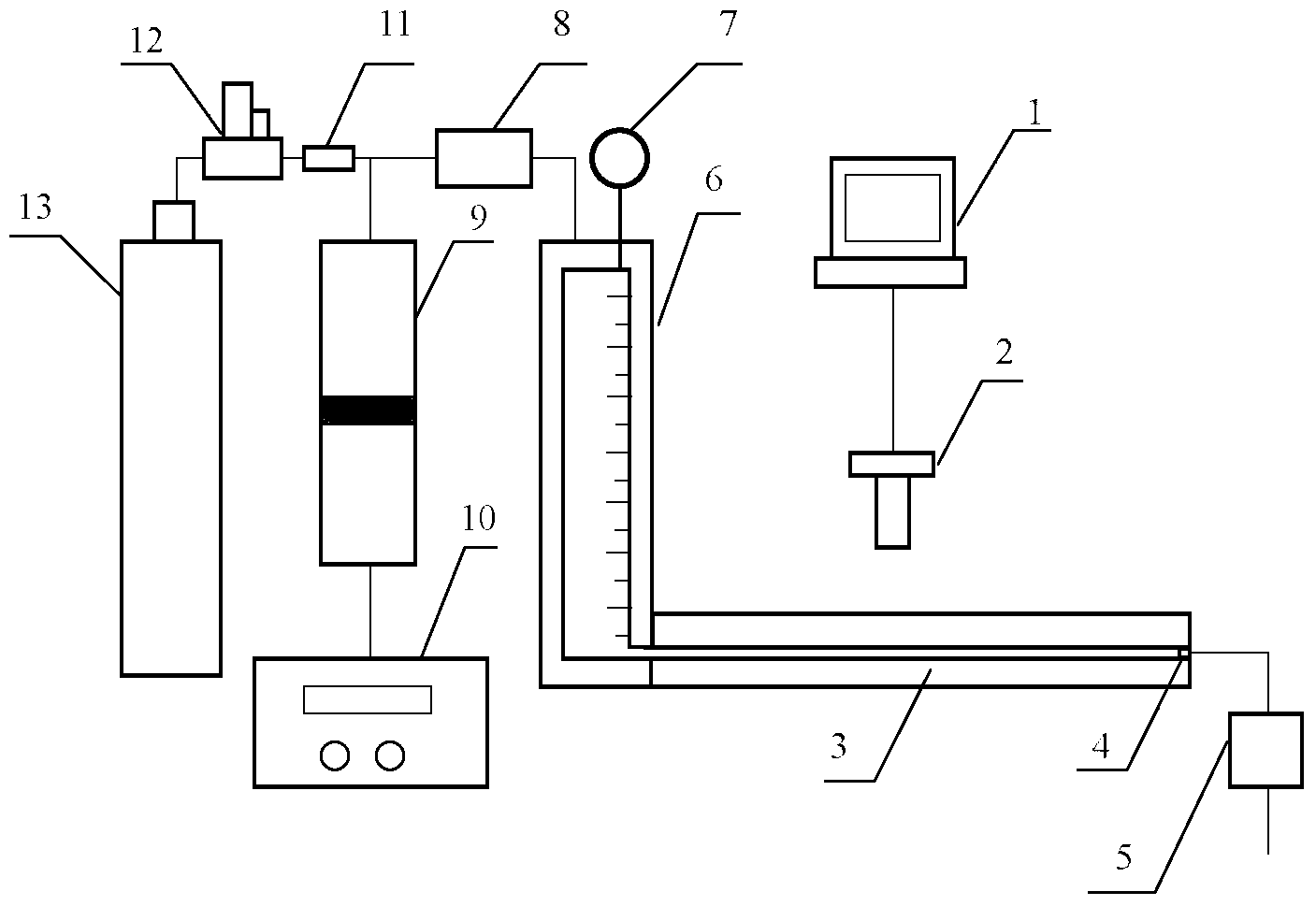

[0047] A device for evaluating the dynamic sand-carrying capacity of foam fracturing fluid, comprising a gas production unit, a fracturing fluid storage unit, a foam generator 8 connected to the gas production unit and the fracturing fluid storage unit, a proppant storage tank 6 and simulated fractures board 3;

[0048] The gas generating part includes a gas cylinder 13, a gas flow meter 12 and a one-way valve 11 sequentially connected along the direction of gas diffusion;

[0049] The fracturing fluid storage part includes a device capable of controlling the outflow of fracturing fluid;

[0050] The gas produced by the gas production unit and the liquid produced by the fracturing fluid storage unit are generated by the bubble generator to generate fracturing fluid foam, and the fracturing fluid foam flows into the top of the proppant storage tank 6;

[0051] A simulated fracture plate 3 is provided at the bottom of the proppant storage tank 6 , and a back pressure valve 5 is...

Embodiment 2

[0059] A foam fracturing fluid dynamic sand-carrying capacity evaluation device as described in Example 1, the difference is that the foam generator 8 is connected to the proppant storage tank 6 through a connecting pipeline, and the connecting pipeline has an inner diameter of 3-6mm stainless steel pipelines.

Embodiment 3

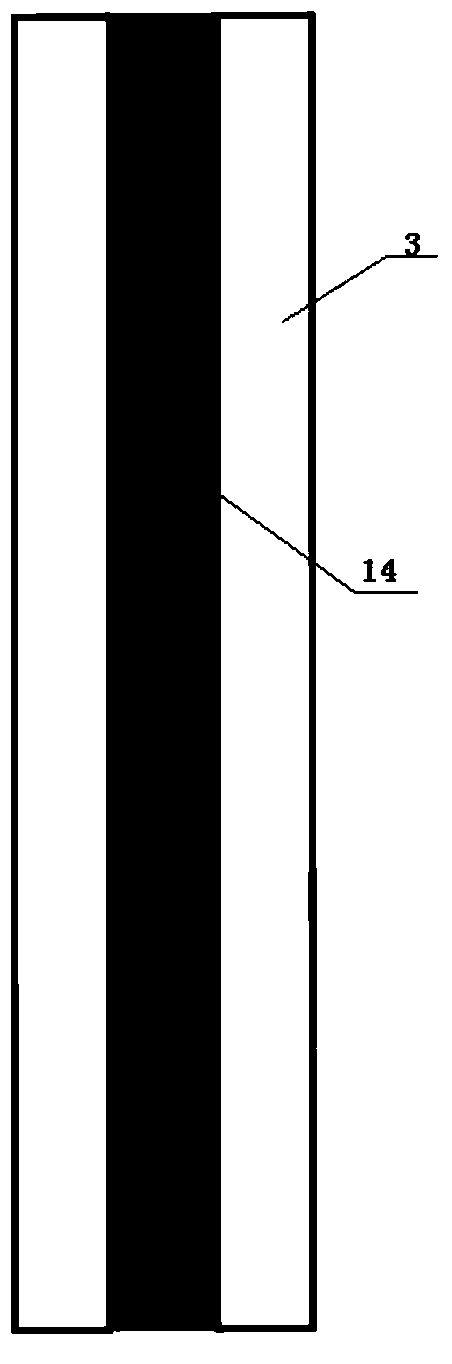

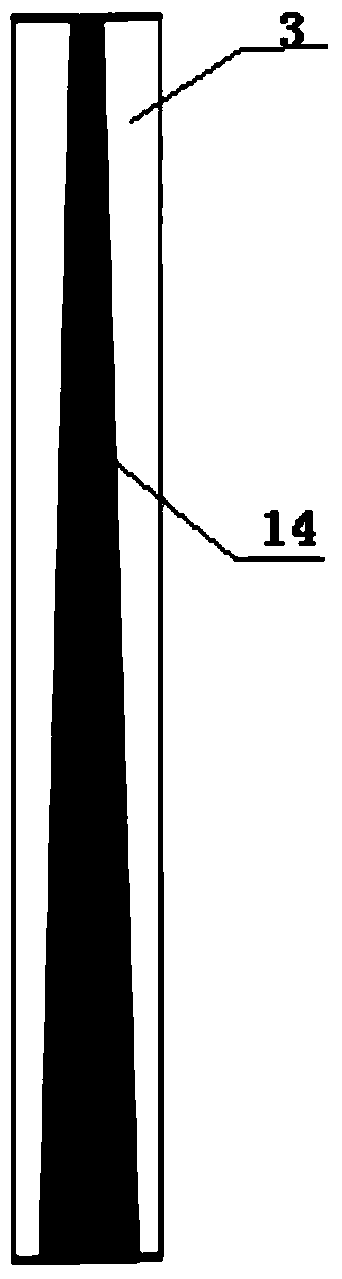

[0061] A device for evaluating the dynamic sand-carrying capacity of foam fracturing fluid as described in Example 1, the difference is that the thickness of the fractures formed by the simulated fracture plate is 1-3mm. The proppant is a proppant particle with a particle diameter of 0.1 mm to 0.9 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com