Equipment intended for manufacturing containers from preforms and comprising mold-decontaminating device, and decontamination method

A decontamination device and preform technology, applied in the field of decontamination, can solve the problems of eliminating pathogens, pollution, and not being specially treated by known solutions, so as to avoid human intervention and optimize the sterilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0090] In the ensuing description, similar or identical elements are denoted by the same numerals.

[0091] In this specification, expressions such as "upstream" and "downstream", "upper" and "lower", "inner" and "outer", "front" and "rear" will be used without limitation according to the definitions given in the description. ”, and use longitudinal, transverse and vertical directions with reference to the coordinate system (X, Y, Z) shown on the drawings.

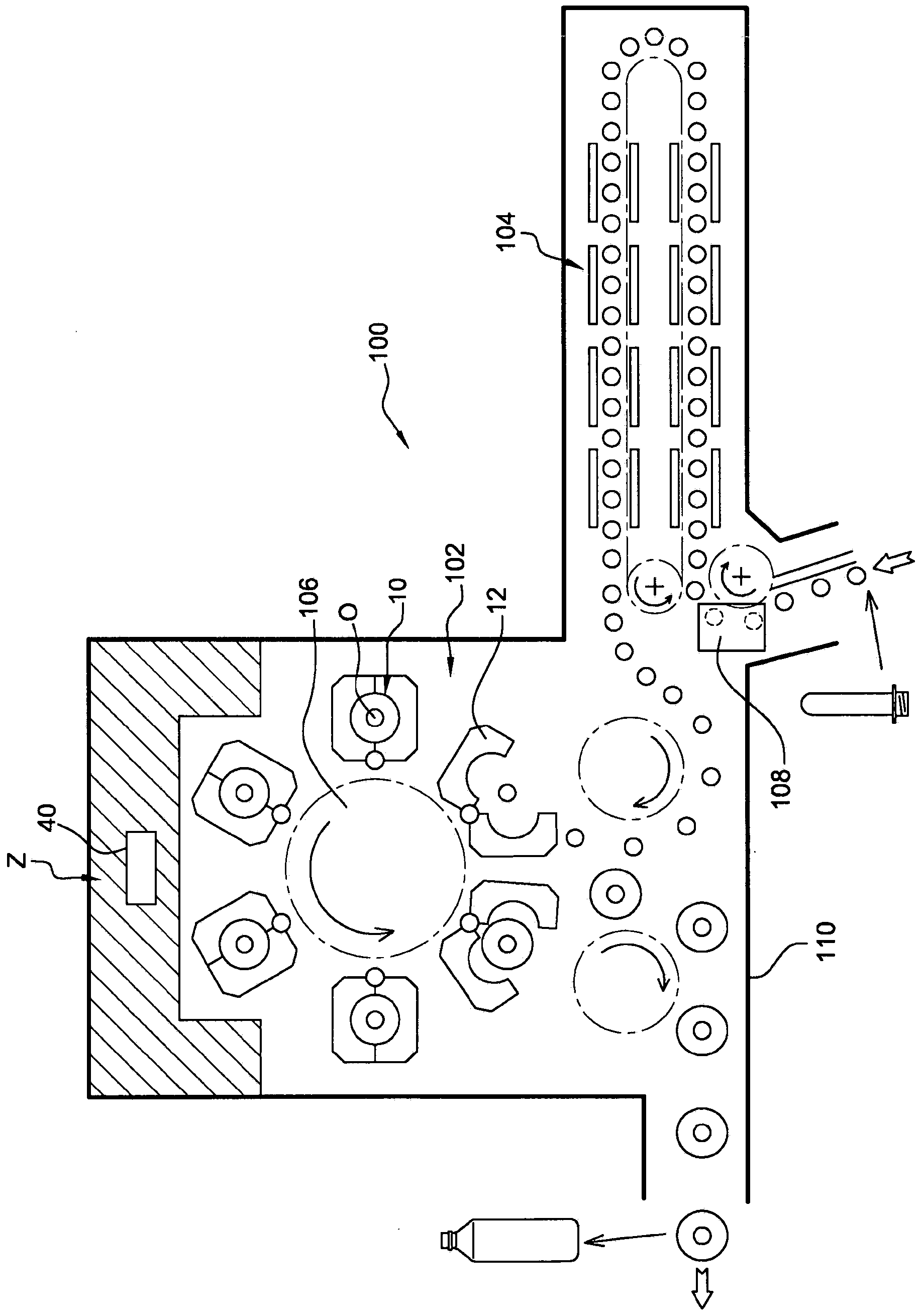

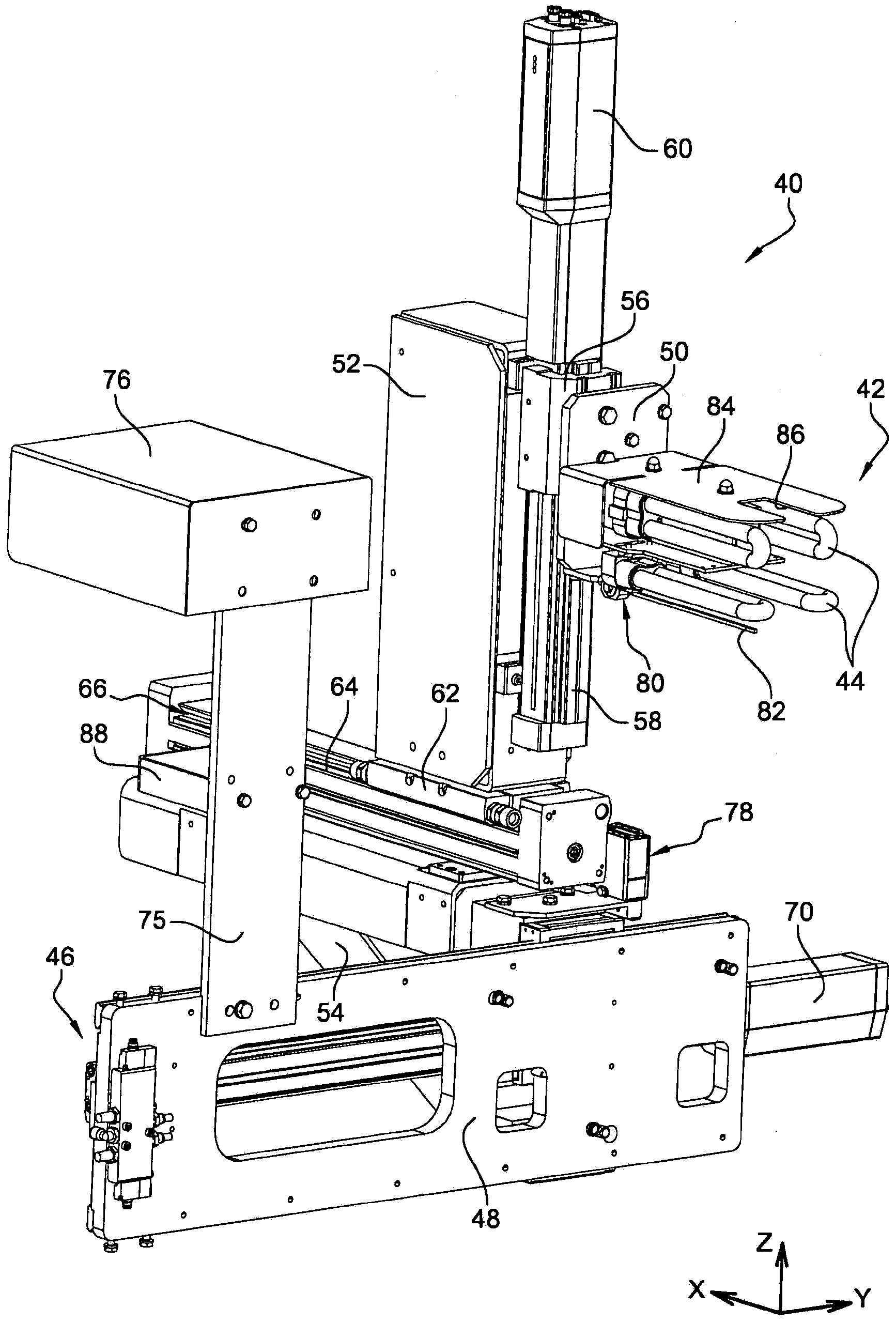

[0092] as stated before, figure 1 An apparatus 100 for manufacturing containers from thermoplastic material preforms is shown.

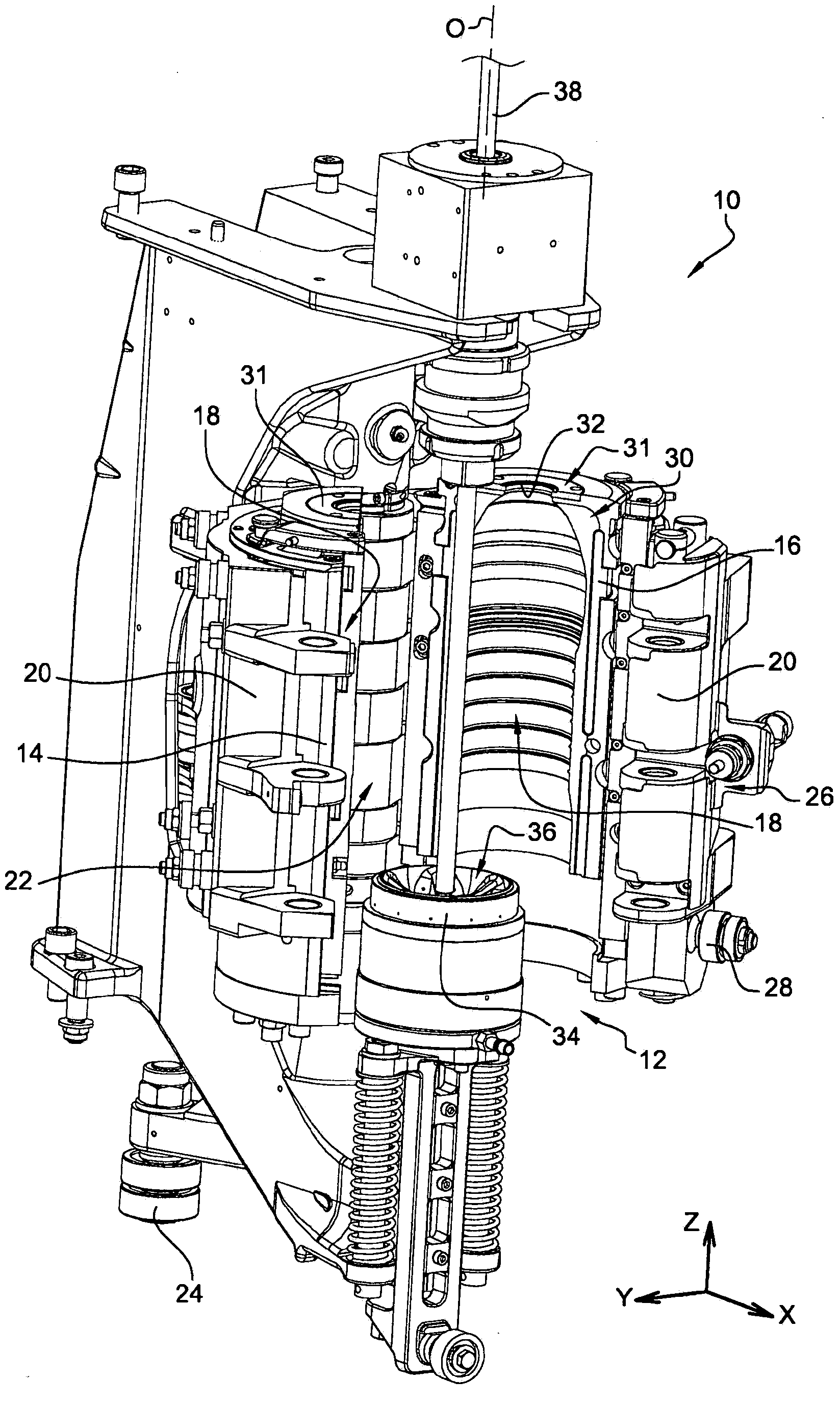

[0093] The apparatus 100 comprises at least one molding machine (or blowing machine) 102 comprising at least one molding device 10 comprising a mold 12 having a main axis (O).

[0094] Preferably, the main axis (O) of the mold 12 of the molding device 10 is associated with the main axis of the preforms intended to be transformed therein when the molding machine 102 is in an operating mode calle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com