Energy-saving updraft barn with uniform air supply

A dense curing room, energy-saving technology, applied in the field of tobacco leaf processing equipment and flue-curing room, can solve the problems of large variation of tobacco leaves, large randomness, prolonged curing time, etc., to expand the area of the main hot air outlet and eliminate the dead area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

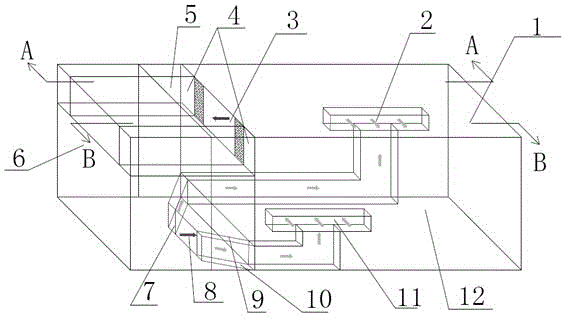

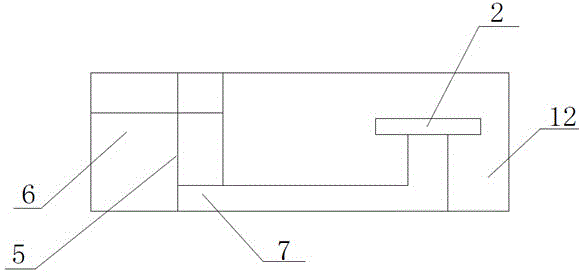

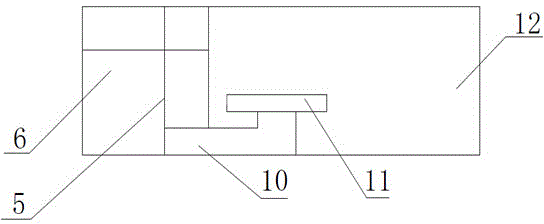

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0020] see Figure 1~Figure 5 , the invention has an energy-saving air-flow ascending dense barn with uniform air supply, which is used for loose-leaf stacking baking, which can reduce the links such as tying rods or clamping smoke on the kang, untying the rope or unclamping and lowering the smoke after roasting, and reducing labor costs. and strength. The dense barn comprises a heating room 6 and a tobacco room 12, the heating room 6 is adjacent to the room 12 and separated by a shared wall 5, that is, the shared wall 5 divides the barn into a heating room 6 and a room 12. In the heating chamber 6, a heating furnace, a heat exchanger and a circulation fan (not shown in the figure) are arranged, and the heat exchanger is used to fully heat the cold air, and then the circulation fan is pressed into the tobacco chamber 12 to bake the tobacco le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com