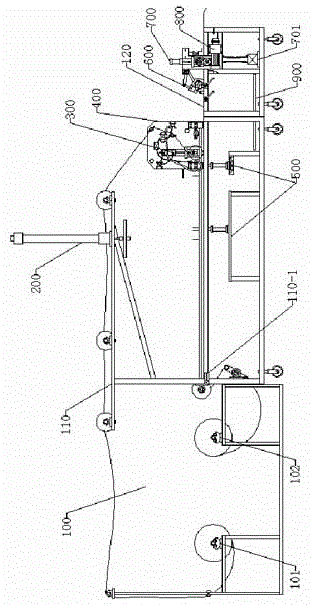

Electric blanket wiring hot-melt trimming compound machine

A technology for electric blankets and composite machines, which can be used in sleeping blankets, travel blankets, beds, etc., and can solve the problems of many operators, high production cost of a single electric blanket, and time-consuming and labor-intensive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

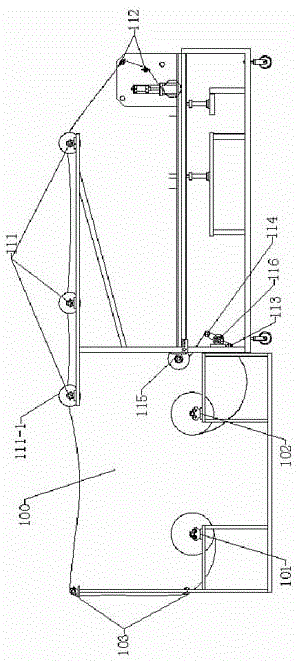

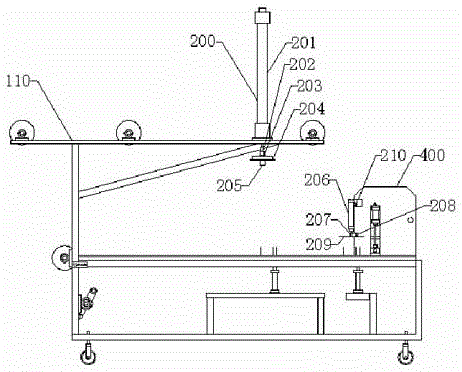

[0069] Embodiment 2: When producing a single-person electric blanket with a specification of 750mm×1500mm, adjust the three cutters of the longitudinal cutter device to be in the cutting state at the same time, select the circuit and operation program in the control box to be in the 750mm×1500mm specification mode, Execute a series of actions of flat laying the lower fabric of the electric blanket, wrapping the fabric around the heating wire, pulling the upper fabric down and spraying fire, hot melting, pressing, and cutting. Two electric blankets are output in one action, and the above actions are repeated continuously to continue Continuously produce single-person electric blankets.

[0070] When it is necessary to produce electric blankets with larger specifications, the spacing adjustment device 900 can be adjusted. Since the wheels for easy movement are installed under the first machine 110 and the second machine 120, when the spacing is adjusted, the rotation is fixed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com