Automatic rough grinding and slurry mixing system and control method of system

A control method and rough grinding technology, applied in the direction of grain processing, etc., can solve the problems of difficult control of proportion and unstable quality of finished products, and achieve the effects of stable mixing ratio, convenient operation and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

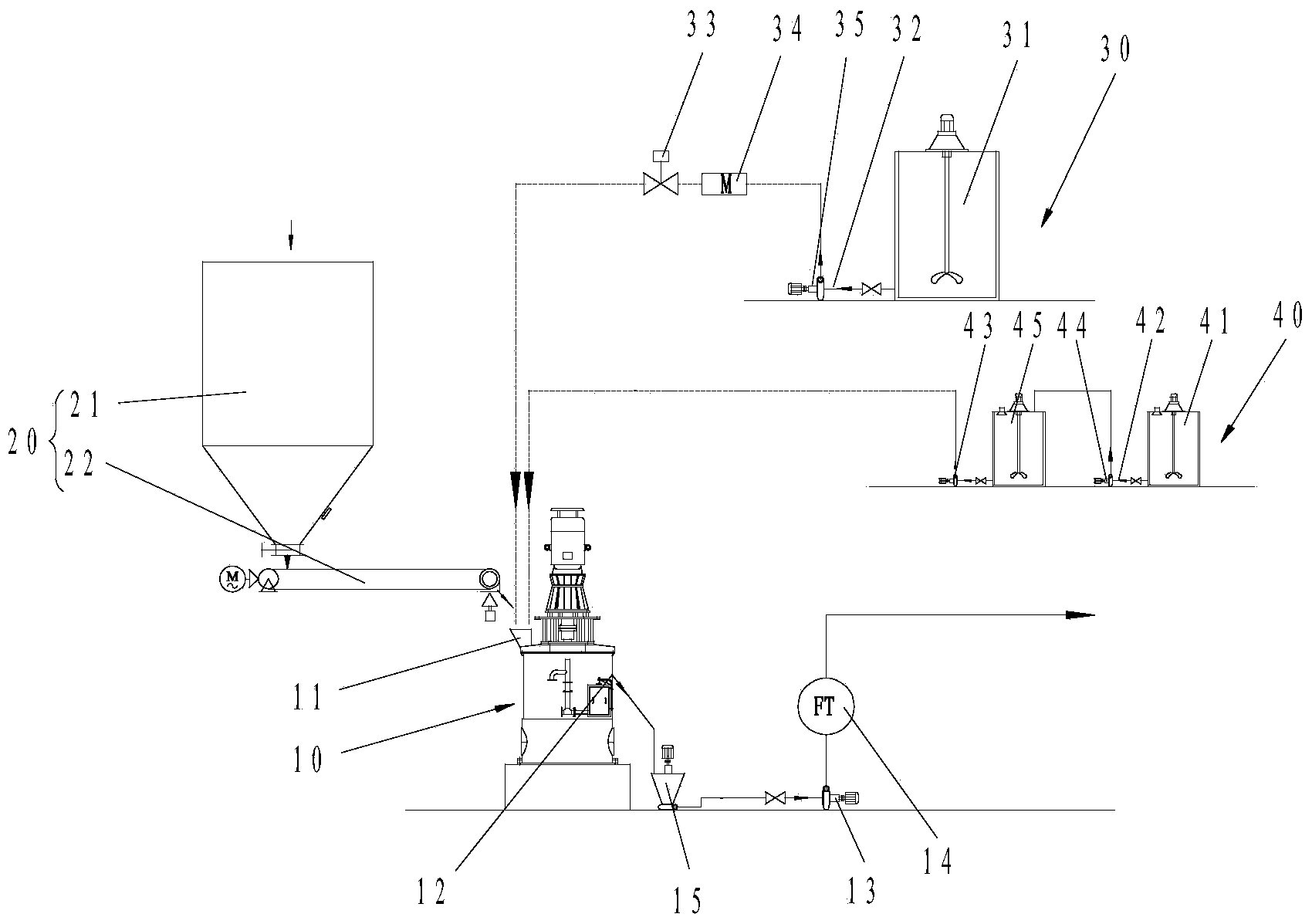

[0037] refer to figure 1 , the preferred embodiment of the present invention provides a coarse grinding automatic slurry mixing system, which is used for coarse grinding of kaolin, comprising a coarse grinder 10, the coarse grinder 10 is provided with a material inlet 11 and a slurry outlet 12, The material inlet 11 is respectively connected with a first input part 20 for introducing mineral material, a second input part 30 for introducing water and a third input part 40 for introducing a dispersant; in the present embodiment, the coarse grinder 10 Three feeding ports 11 can be provided on the top, respectively corresponding to the first input part 20, the second input part 30 and the third input part 40, so that each input part is introduced into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com