Forming method of shaft parts with flanges

A technology of shaft parts and forming methods, which is applied in the direction of manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc., and can solve the problems of increasing equipment investment costs, large tonnage of forming equipment, and high equipment input costs , to achieve the effect of reducing input cost, reducing forming force and reducing extrusion area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

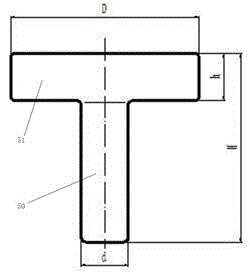

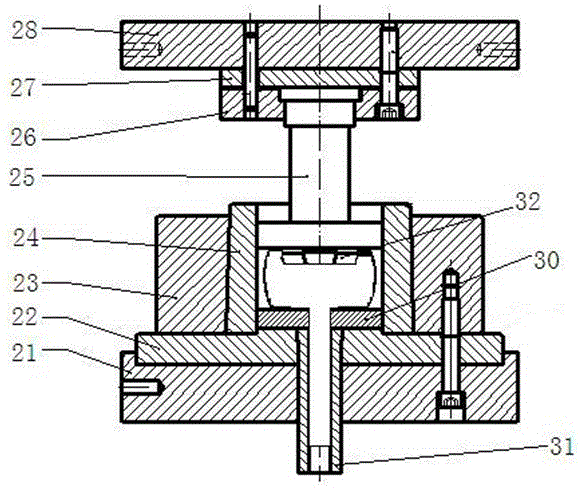

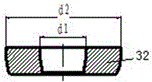

[0026] Examples of forming methods for shaft parts with flanges Figure 2~13 As shown: the following steps are included. The first step is to select a rod-shaped blank. The diameter of the rod-shaped blank is larger than the diameter of the shaft part of the shaft part and smaller than the diameter of the flange of the shaft part. The structure of the rod-shaped blank is as follows figure 2 As shown, D1 represents the diameter of the rod-shaped blank, and h0 represents the height of the rod-shaped blank; the second step is to extrude one end of the rod-shaped blank through the extrusion die, so that the rod-shaped blank is formed into the shaft part of the shaft , the structure of the extrusion die is as Figure 7 As shown: the extrusion die includes an extrusion upper die part and an extrusion lower die part, the extrusion upper die part includes an extrusion upper die base 8, and the lower end of the extrusion upper die base 8 is detachably connected with an extrusion upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com