Device with axially clamped plunger for amplifying the input force

A technology of input force and equipment, applied in the direction of transportation and packaging, vehicle parts, brakes, etc., can solve the problems of complexity, high manufacturing cost and high weight, and achieve the effect of improving air guidance, reducing component prices and reducing forming force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

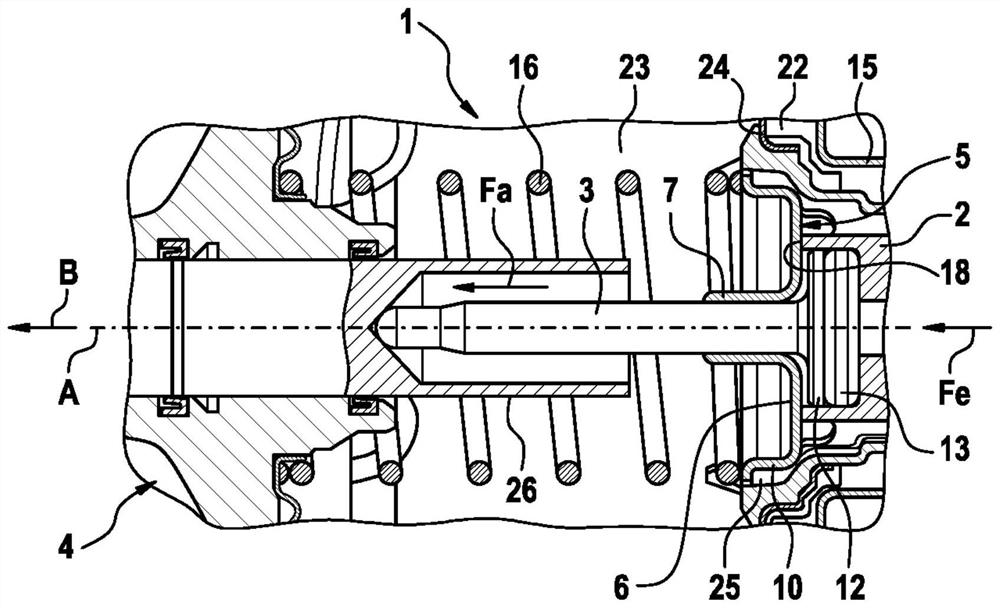

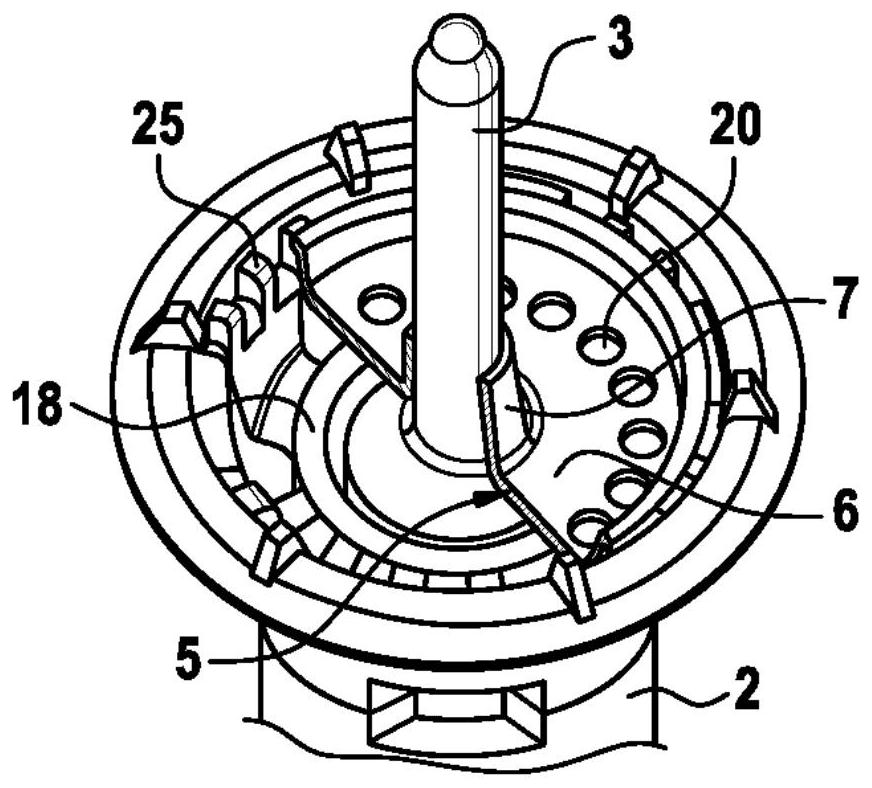

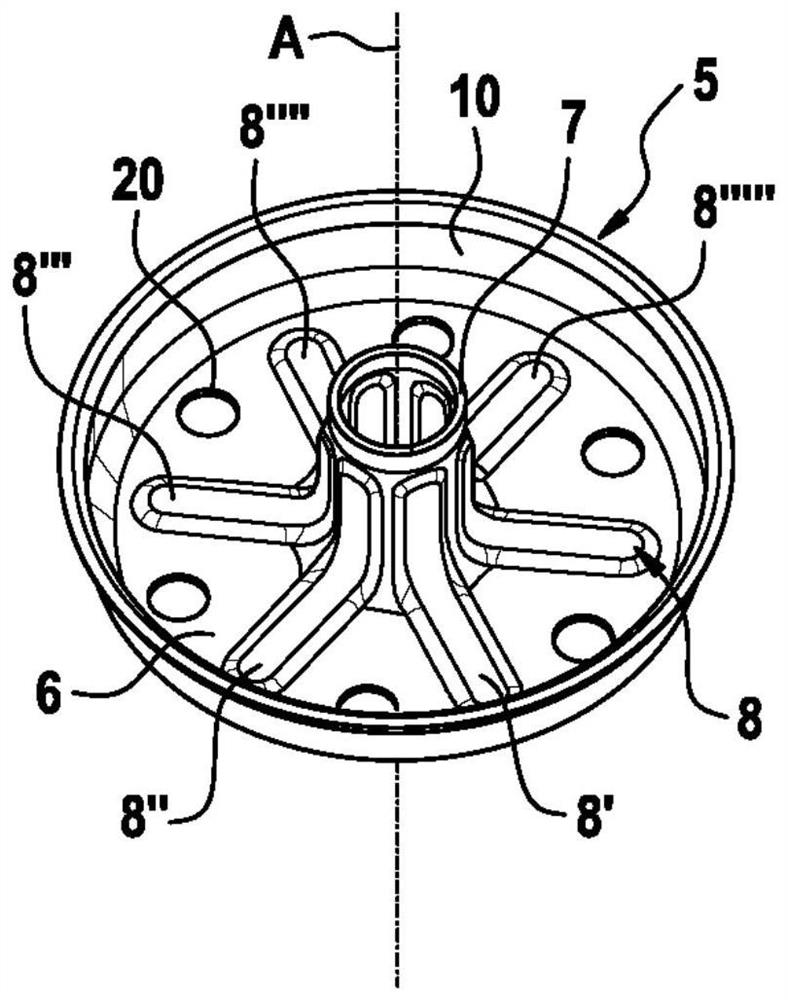

[0019] figure 1 and figure 2

[0020] In such a device 1 , which is designed as a pneumatic brake booster, the input force Fe generated by the driver is introduced and amplified by means of a vacuum chamber 23 arranged in the housing 15 and a ventilated air-exhaust system. The pressure difference between the working chambers 22 acts on the movable working wall 24 with a large surface which can seal the separation of the two chambers and through the module 2 coupled thereon and clamped on the module 2 with a structure configured to The pressure rod 3 between the pistons 26 of the force receiving device 4 of the master cylinder is output to the piston 26 as an amplified output force Fa.

[0021] The pressure lever 3 is of rotationally symmetrical design with respect to the actuating axis A and, in addition to the elongated pin-shaped cylindrical body, has a radially expanded flat base 12 on the module side, by means of which the pressure lever is axially It rests on an elast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com