Method for producing motor vehicle component from extruded aluminium profile

A technology of extrusion direction and profile, applied in the direction of vehicle components, superstructure, superstructure sub-assembly, etc., can solve the problem of high manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037]The same reference numbers are used in the figures for identical or similar components, even if their description is not repeated for reasons of simplification.

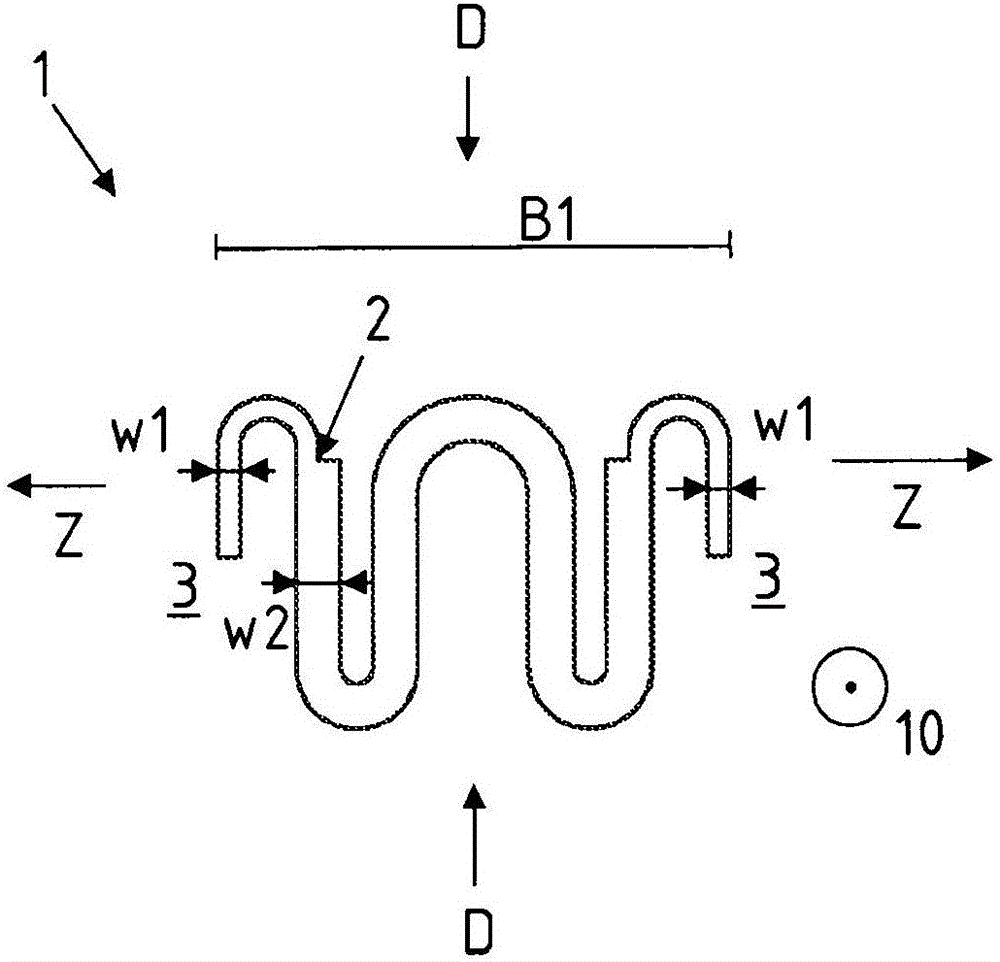

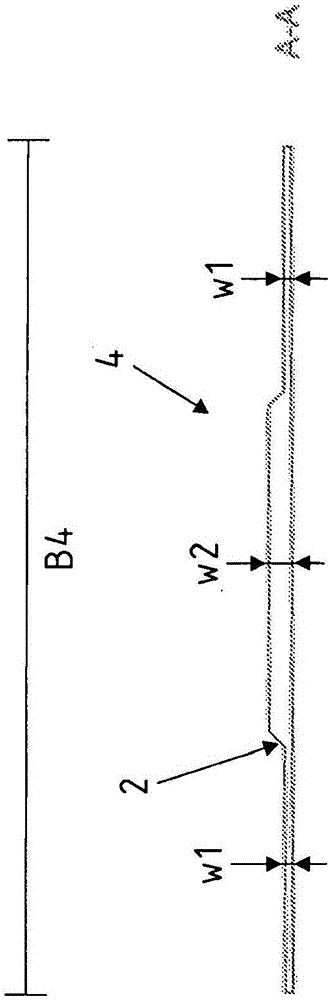

[0038] figure 1 The profile 1 produced according to the invention is shown in cross section. It can be clearly seen that the profile 1 has an uneven cross-sectional profile which is in particular undulating and W-shaped. Furthermore, it can be seen that the profile 1 has two different wall thicknesses w1 and w2 in cross section, wherein w2 is here greater than w1. Furthermore, the wall thickness w1 is constant here and the wall thickness w2 is constant in the corresponding area over the cross-sectional distribution. However, it is conceivable within the scope of the invention that the wall thicknesses w1 , w2 also be varied, for example increased or decreased, since there is a degree of freedom of shaping with respect to the wall thicknesses w1 , w2 , especially in connection with extrusion. A sudden change ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com