Automobile part thermal forming system and operating method thereof

A technology of auto parts and thermoforming, applied in the field of machinery, can solve the problem of inability to satisfy customers, and achieve the effect of good forming performance, small mold loss and improving tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

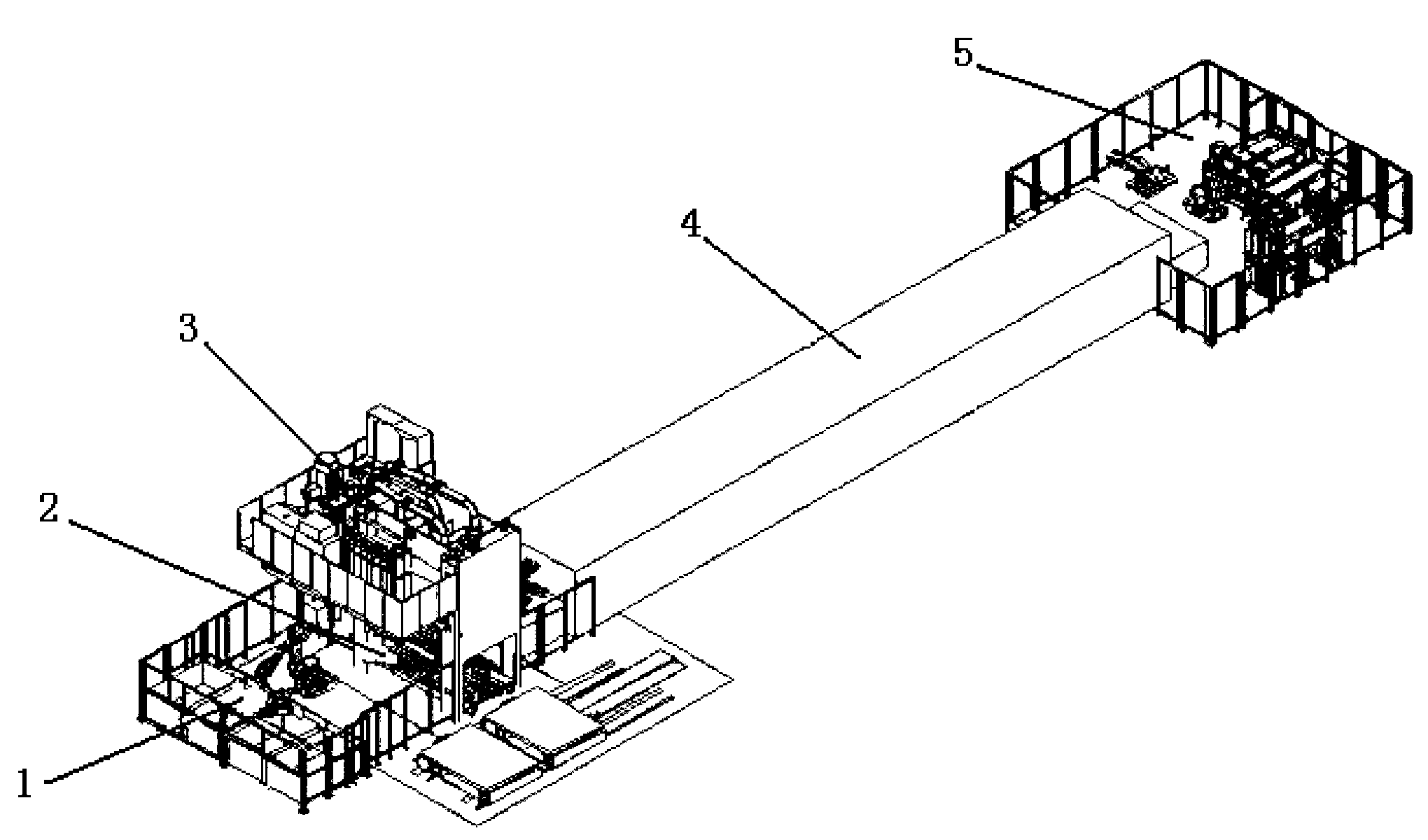

[0015] The present invention will be further described below according to the accompanying drawings.

[0016] Such as figure 1 As shown, the front of the feeding device 5 is provided with the entrance of the heating furnace 4, the outlet of the heating furnace 4 is connected to the press 3, and the front of the press 3 is provided with the unloading device 1; the bottom of the press 3 is provided with the mold 2.

[0017] The working steps of the thermoforming system are as follows:

[0018] (1) Feeding: Cut the raw steel plate according to the requirements and place it in the feeding device with the manipulator;

[0019] (2) Heating: The manipulator of the feeding device places the cut steel plate at the entrance of the heating furnace, and uses the conveyor belt to transport the steel plate into the heating furnace for heating and transports it to the exit of the heating furnace;

[0020] (3) Hot press forming: the steel plate transported to the exit of the heating furnace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com