Tool for boring and reaming

A boring tool and reamer technology, applied in reamers, tools for lathes, manufacturing tools, etc., can solve the problems of reducing processing efficiency and troubles, and achieve the effect of large aperture change range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

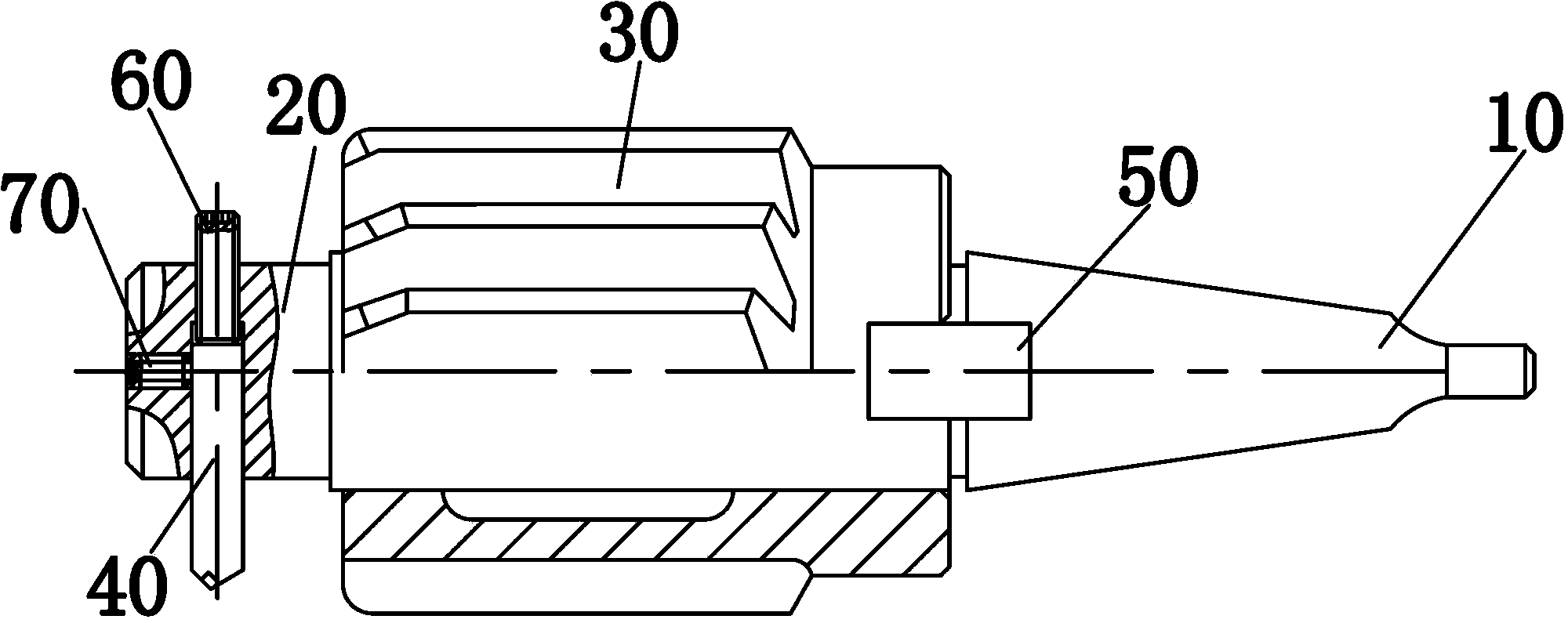

[0010] The invention discloses a tool for boring and reaming, which comprises a tapered shank, a tool bar, a sleeve reamer and a boring tool; the front end of the tool bar is provided with a boring tool installation hole, and the boring tool is installed on the On the hole, a part protrudes from the boring tool installation hole; the sleeve reamer is detachably socketed on the cutter bar; the sleeve reamer is in clearance fit with the cutter bar, and an adjusting screw is also included; The adjusting screw is a hexagon socket head cap screw. A fastening screw is also included; the fastening screw is an inner hexagonal screw.

[0011] The above-mentioned embodiments only express several implementation modes of the present invention, and the description thereof is relatively specific and detailed, but should not be construed as limiting the patent scope of the present invention. It should be pointed out that those skilled in the art can make several modifications and improvemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com