Multi-evaporation-section heat pipe coupling buried pipe system

An evaporation section, coupled ground technology, applied in the field of high-efficiency horizontal buried pipe system, can solve the problems of slow heat transfer rate, single heat absorption and transfer, etc., to achieve the effect of rapid transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the solutions and principles of the present invention more clear to those skilled in the art, the following describes in detail in conjunction with the drawings and specific embodiments. The content of the present invention is not limited to any specific embodiment, nor does it represent the best embodiment, and general substitutions known to those skilled in the art are also covered within the protection scope of the present invention.

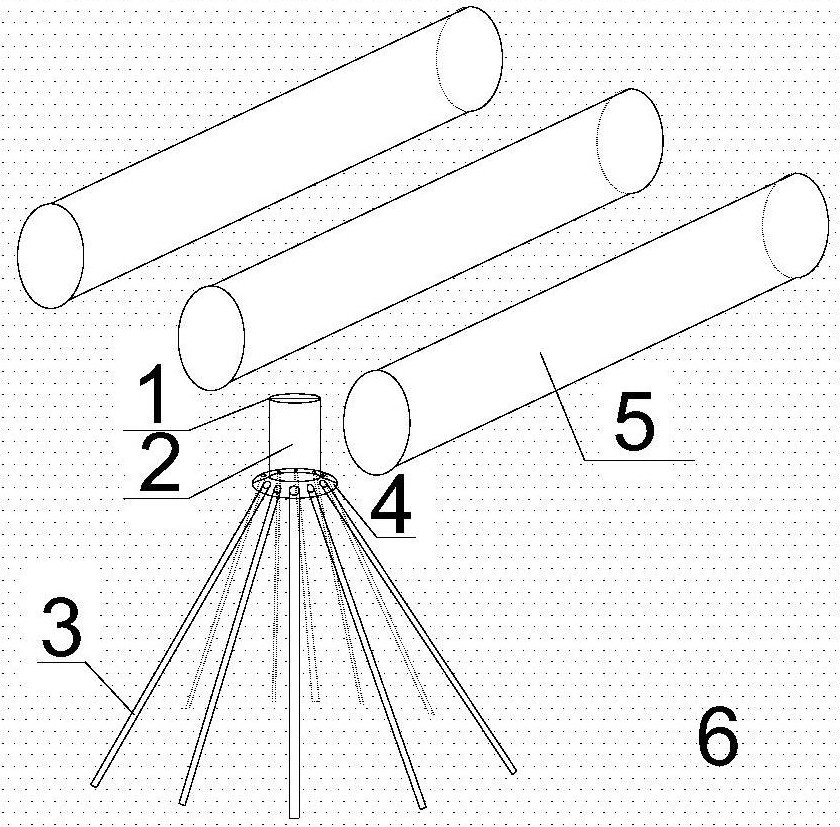

[0020] Such as figure 1 As shown, this embodiment provides a multi-evaporation-section heat pipe coupled buried pipe system, including a horizontal buried pipe 5 arranged in the soil 6, a gravity-type heat pipe 1 with multiple evaporation sections buried under the horizontal buried pipe 5, and multiple evaporation sections. The evaporating section gravity heat pipe 1 is filled with refrigerant inside, and the multi evaporating section gravity heat pipe 1 includes multiple evaporating sections 3 at the bottom, and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com