A method of directly using a razor blade to prepare a three-dimensional metal microneedle array

A microneedle array and blade technology, applied in the field of medical devices, can solve the problems of affecting the sharpness of microneedle tips, making it difficult to meet mass production, increasing procedures and costs, etc., so as to improve the safety of use, reduce the cost of use and maintenance, and improve carrying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Example 1: Preparation of half-chip microneedle array

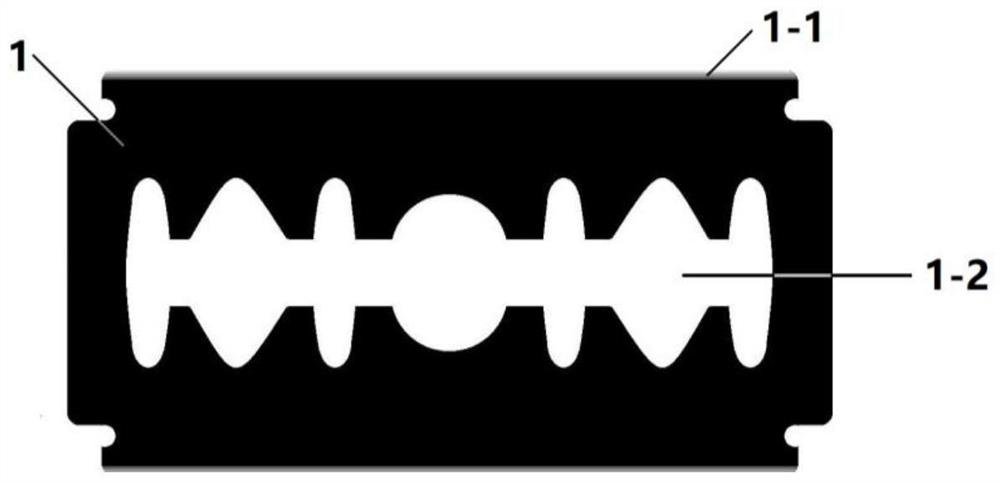

[0064] S1: Double-sided razor blades 1 are directly used as raw materials for microneedles (such as Flying Eagle 74-C or 74-S series double-sided blades, Gillette Super Blue double-sided blades, etc.). 22 mm, the width of the blade portion 1-1 is about 0.5 mm.

[0065] S2: Processing special blade clamping tooling for blade processing

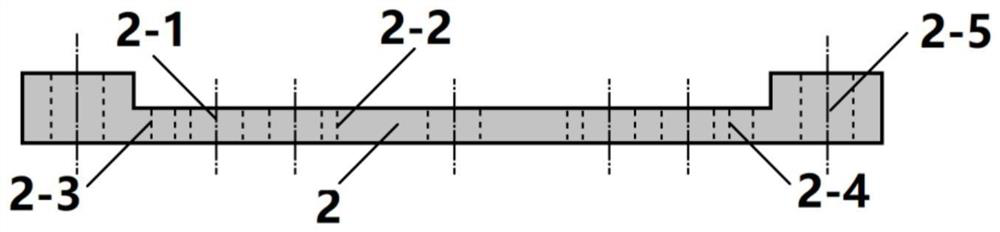

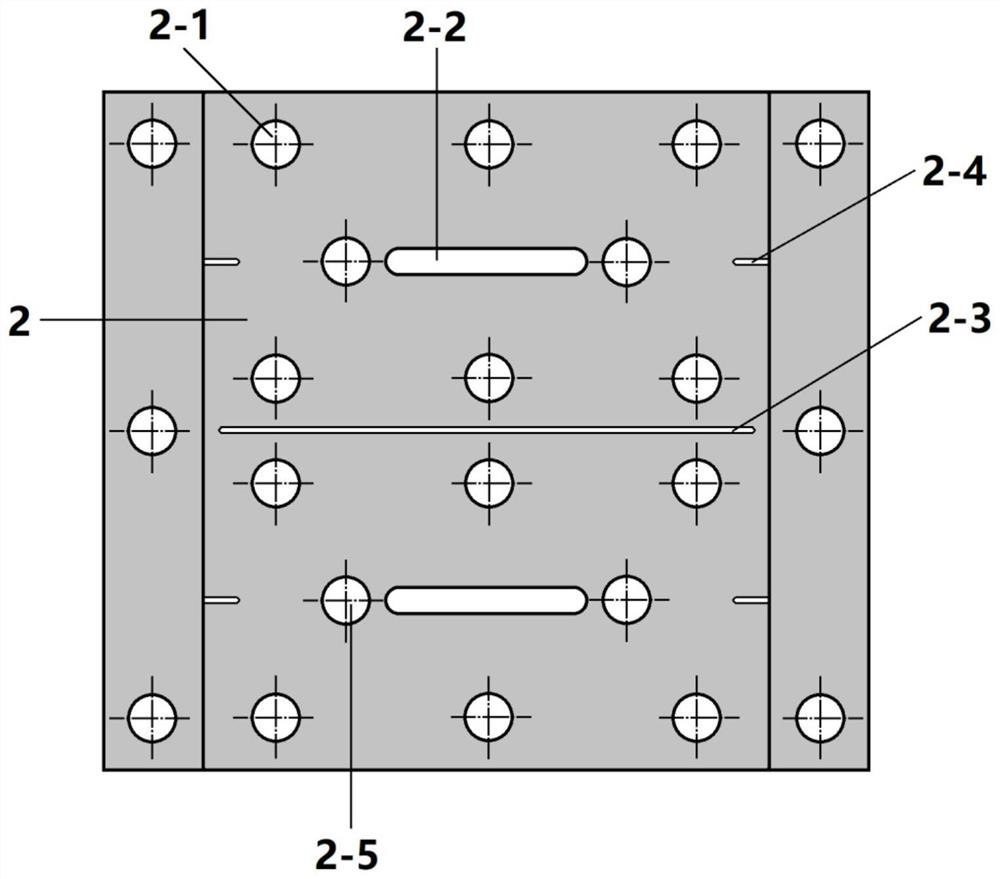

[0066] The tooling structure is composed of upper and lower cover plates, and the upper cover plates are as follows: figure 2 , image 3 and Figure 4 As shown, the lower cover is as follows Figure 5 , Figure 6 and Figure 7 shown. The cover plate is made of stainless steel with high strength and hardness. The overall length of each cover plate is 83 mm. The overall width is 46 mm, so that the blades on both sides have an overlap of about 0.3-0.5 mm in the middle, but the outer blade is hidden in the cover to prevent damage to the blade or the processed needle point duri...

Embodiment 2

[0074] Example 2: Preparation of a whole-chip microneedle array

[0075] S1: Microneedle raw materials directly use double-sided razor blades 1, such as Flying Eagle 74-C or 74-S series double-sided blades, Gillette Super Blue double-sided blades, etc. The outer contour is about 43 mm long and 22 mm wide. mm, the width of the blade portion 1-1 is about 0.5 mm.

[0076] S2: Processing special blade clamping tooling for blade processing

[0077] The tooling structure is composed of upper and lower cover plates, and the upper cover plates are as follows: figure 2 , image 3 and Figure 4 As shown, the lower cover is as follows Figure 5 , Figure 6 and Figure 7shown. The cover plate is made of stainless steel with high strength and hardness. The overall length of each cover plate is 83 mm. The overall width is 46 mm, so that the blades on both sides have an overlap of about 0.3-0.5 mm in the middle, but the outer blade is hidden in the cover to prevent damage to the bl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com