A dry-jet wet spinning spinneret and its manufacturing method

A technology of dry-jet wet spinning and spinneret device, which is applied in the direction of dry spinning, wet spinning, spinneret assembly, etc., which can solve the problems of lower production efficiency, high cost, increased maintenance cycle and cost, etc., and achieve simplification Effect of combining steps and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

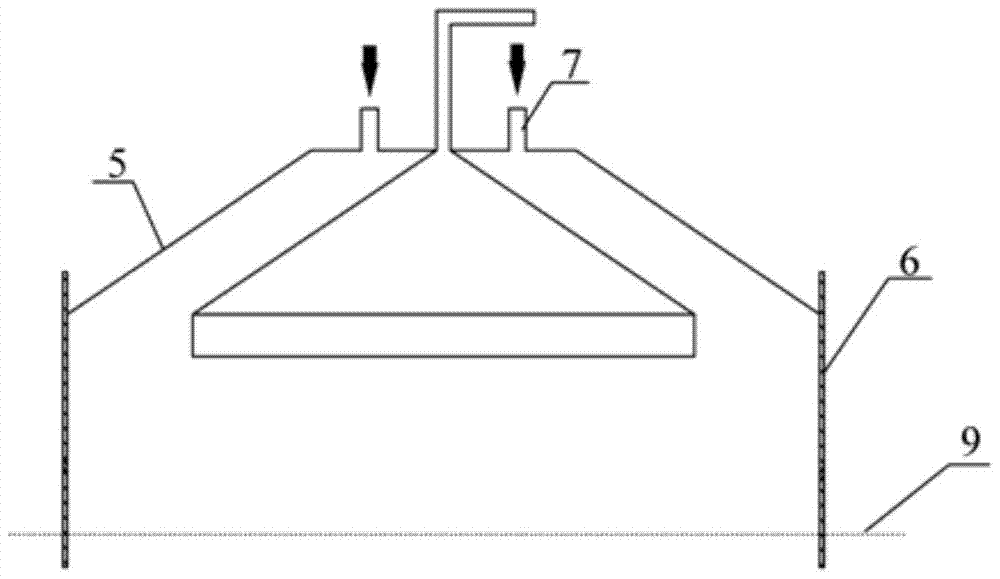

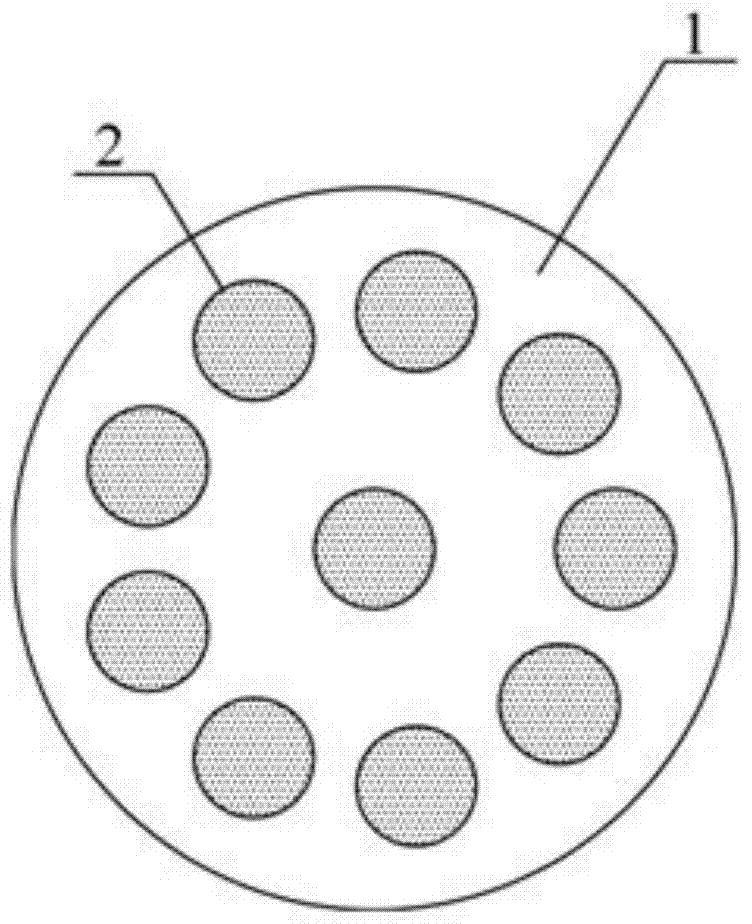

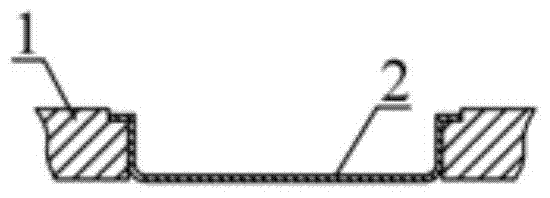

[0037] Such as figure 1 and image 3 As shown, a kind of dry-jet wet spinning spinneret comprises fairing and spinneret, and spinneret is installed in the inside of fairing, and the upper end of fairing is provided with a plurality of air inlets 7, and a plurality of air inlets 7 The distribution is symmetrical with respect to the symmetrical axis of the spinneret, and the air inlet 7 is connected to the gas supply device; the lower part of the fairing is immersed in the coagulation bath to form a closed air chamber, and the fairing is located above and close to the liquid surface. Air port 8. A conical spinneret 3 is arranged above the spinneret, and the top of the conical spinneret 3 is connected to the spinning stock solution injection pipeline 4, and the fairing can be formed integrally or in a split structure. When the fairing is a split During ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com