Freeze-thaw centrifugal model box in the freeze-thaw deformation centrifugal simulation system

A centrifugal model, freeze-thaw technology, applied in the direction of material inspection, soil material testing, etc., can solve the problem of few freeze-thaw centrifugal model tests, etc., to achieve the effect of flexible adjustment of elongation, simple and convenient use, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and embodiment do further explanation

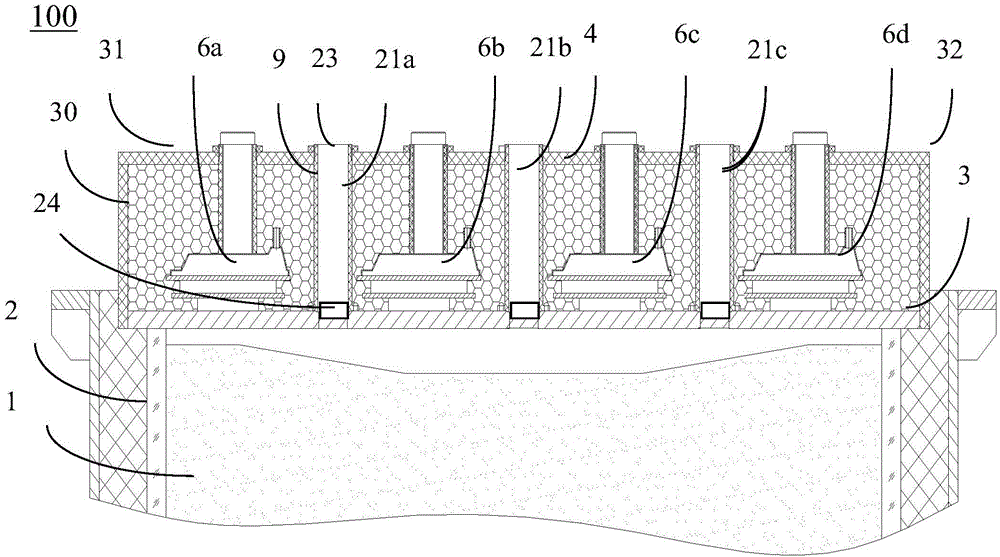

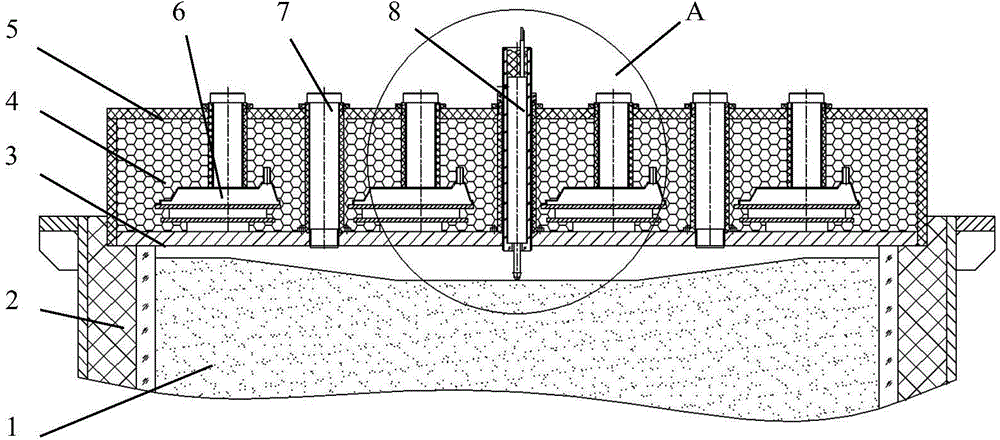

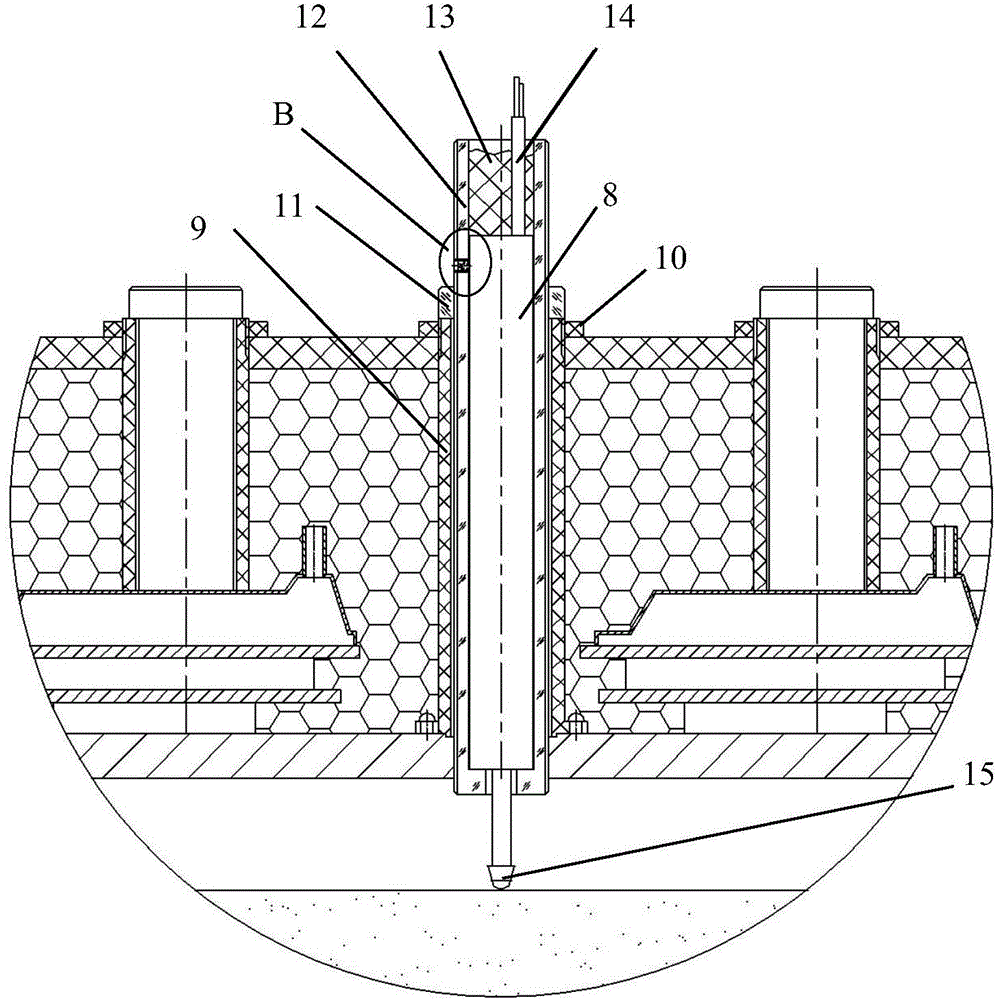

[0031] like figure 1 As shown, the freeze-thaw centrifugal model box 100 in the freeze-thaw deformation centrifugal simulation system includes a heat exchange system 30 and a model box 2. The model box 2 is a box structure with thermal insulation performance, and a soil model 1 is arranged in the model box 2. The heat exchange system 30 covers the tank opening of the mold tank 2 . The heat exchange system 30 is composed of a sealed box 31 and a plurality of semiconductor devices 6 arranged in the sealed box 31 . The heat exchange top cover 32 of polyoxymethylene plate, the frame and the heat exchange bottom plate 3 of aluminum alloy material form a cuboid sealed box body 31 . A plurality of semiconductor devices 6 a , 6 b , 6 c , 6 d are arranged at intervals on the heat exchange base plate 3 and are closely connected with the heat exchange base plate 3 . The rest of the space in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com