Honeycomb ground paper production line device

A technology of honeycomb paper and production line, which is applied in the direction of cardboard items, etc., can solve the problems of low production efficiency, inapplicability, and absence of paper honeycomb blanks for handicrafts, etc., and achieve the effect of high production efficiency and low production cost of equipment manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

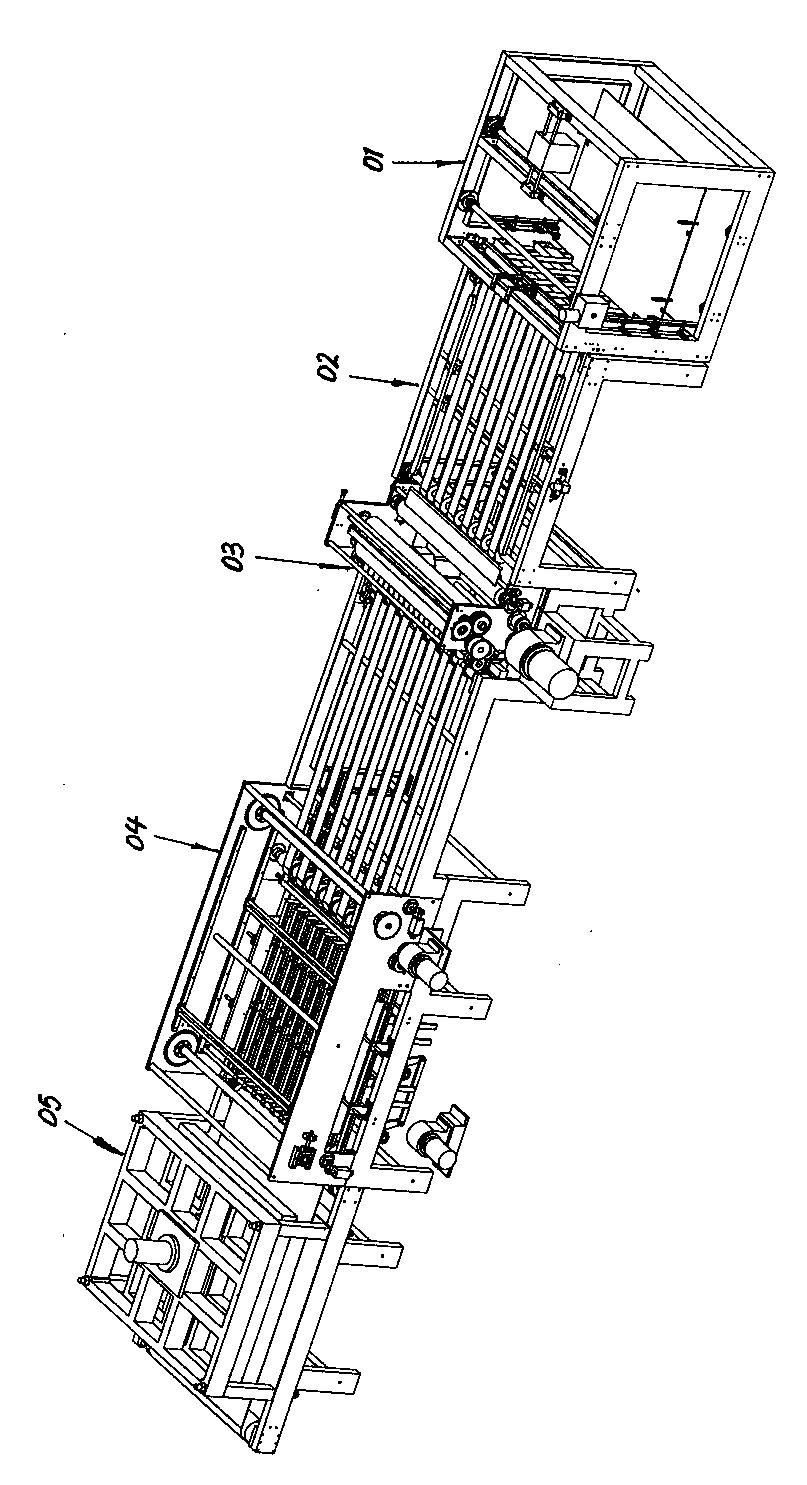

[0062] The present invention includes the present invention consisting of a single-sheet automatic paper feeding device 01, a centering belt conveyor 02, a single rubber roller double-station gluing machine 03, an automatic stacking conveyor device 04, and a compactor 05.

[0063] Sheet-fed automatic paper feeder 01 is a feeder.

[0064] Centering belt conveyor 02 is a belt conveyor with clappers on the left and right sides of the frame to push the paper on the belt to the middle during the conveying process.

[0065] The centering belt conveyor 02 conveys the single-sheet paper input by the single-sheet automatic paper feeding device 01 to the single rubber roller double-station gluing machine 03.

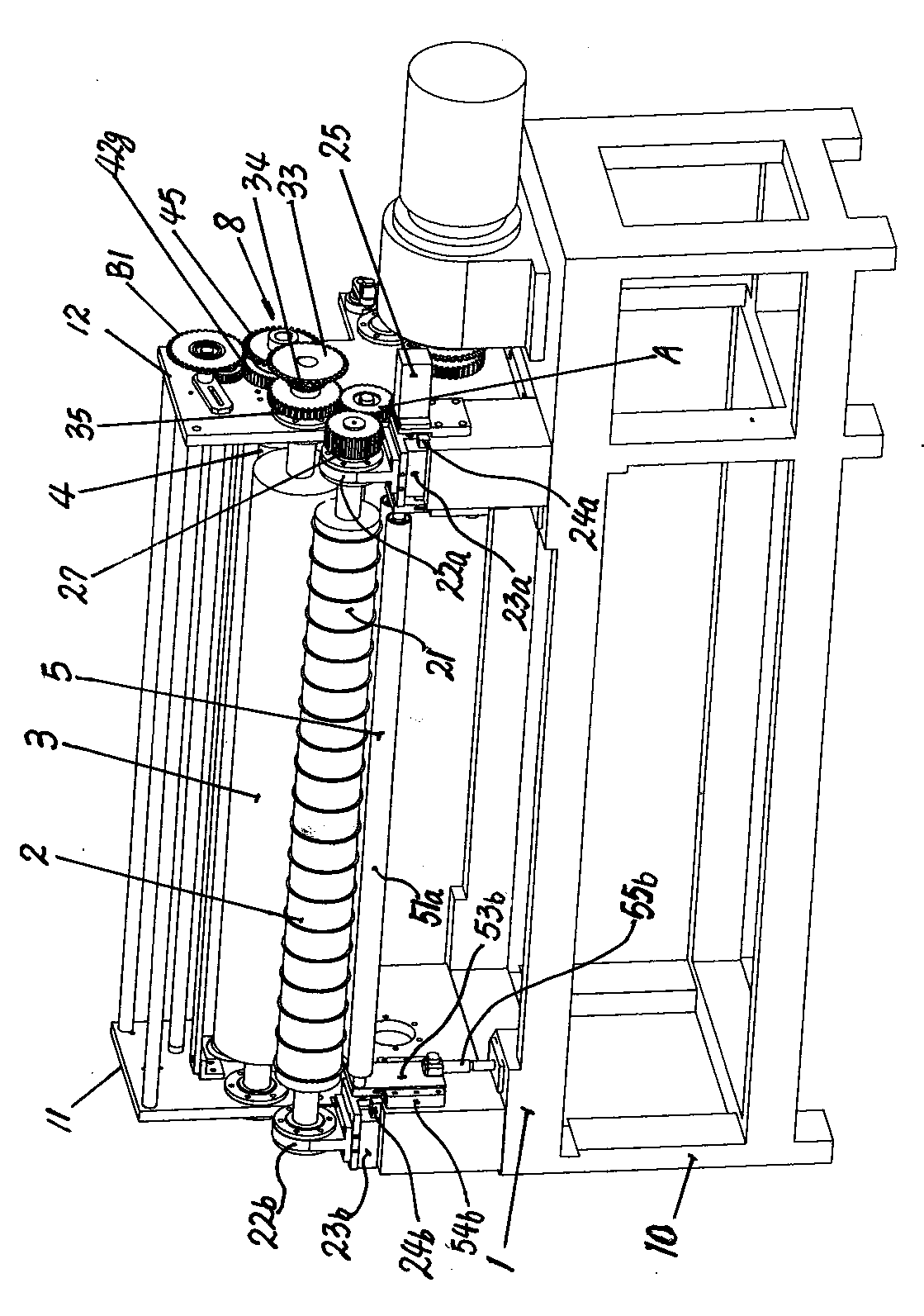

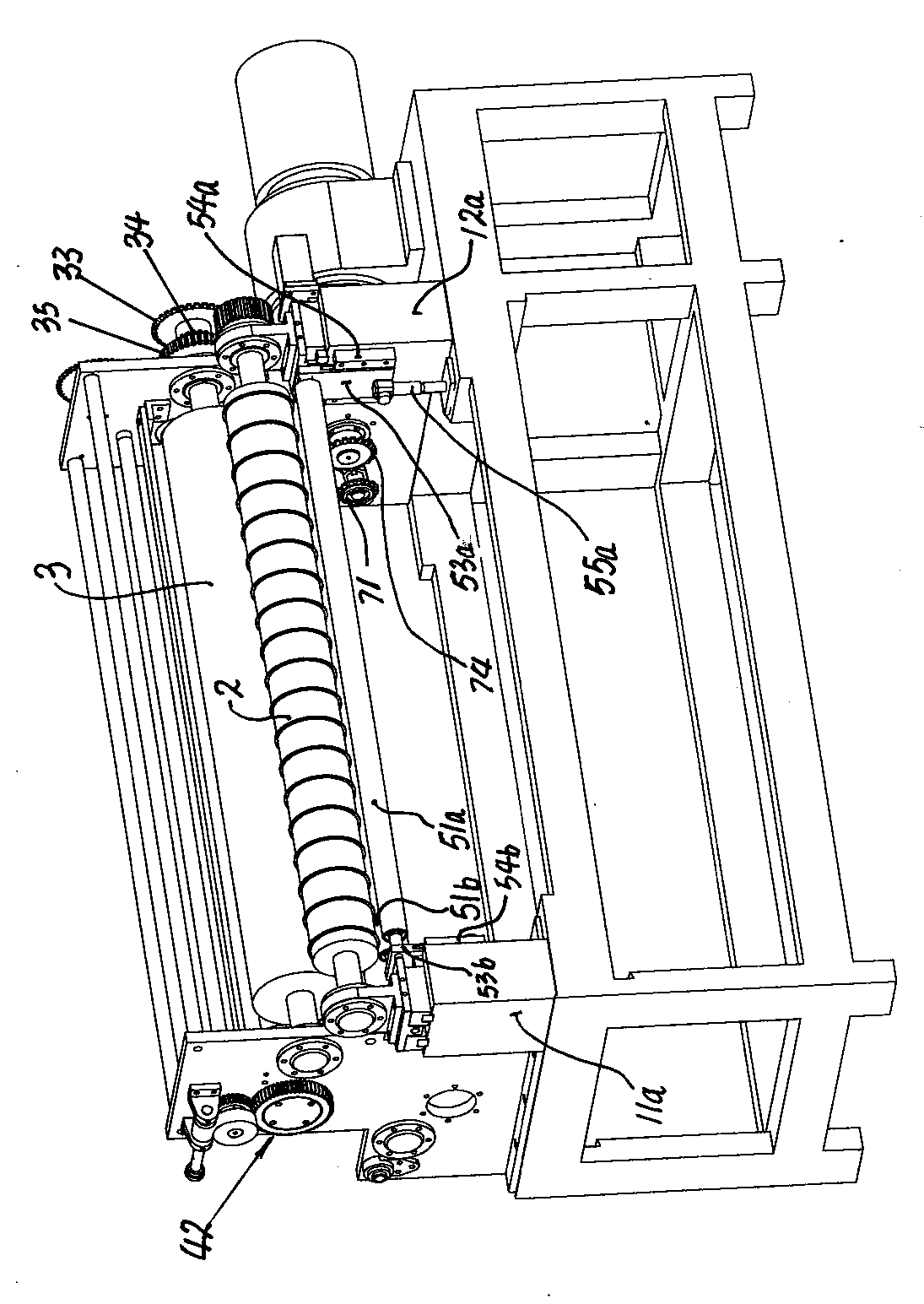

[0066] Single rubber roller double station gluing machine 03 consists of frame 1, rubber coating roller device 2, rubber transfer roller 3, calibrating roller device 4, paper supporting roller device 5, paper ejecting device 6, paper guide roller 7, transmission device 8 composit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com