Car retarder with detachable steel rail carriers

A technology of reducer and rail, which is applied in the field of vehicle reducer, which can solve the problems of increasing the difficulty of brake calipers and the inability of the rail seat to be independently suspended, so as to reduce the workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

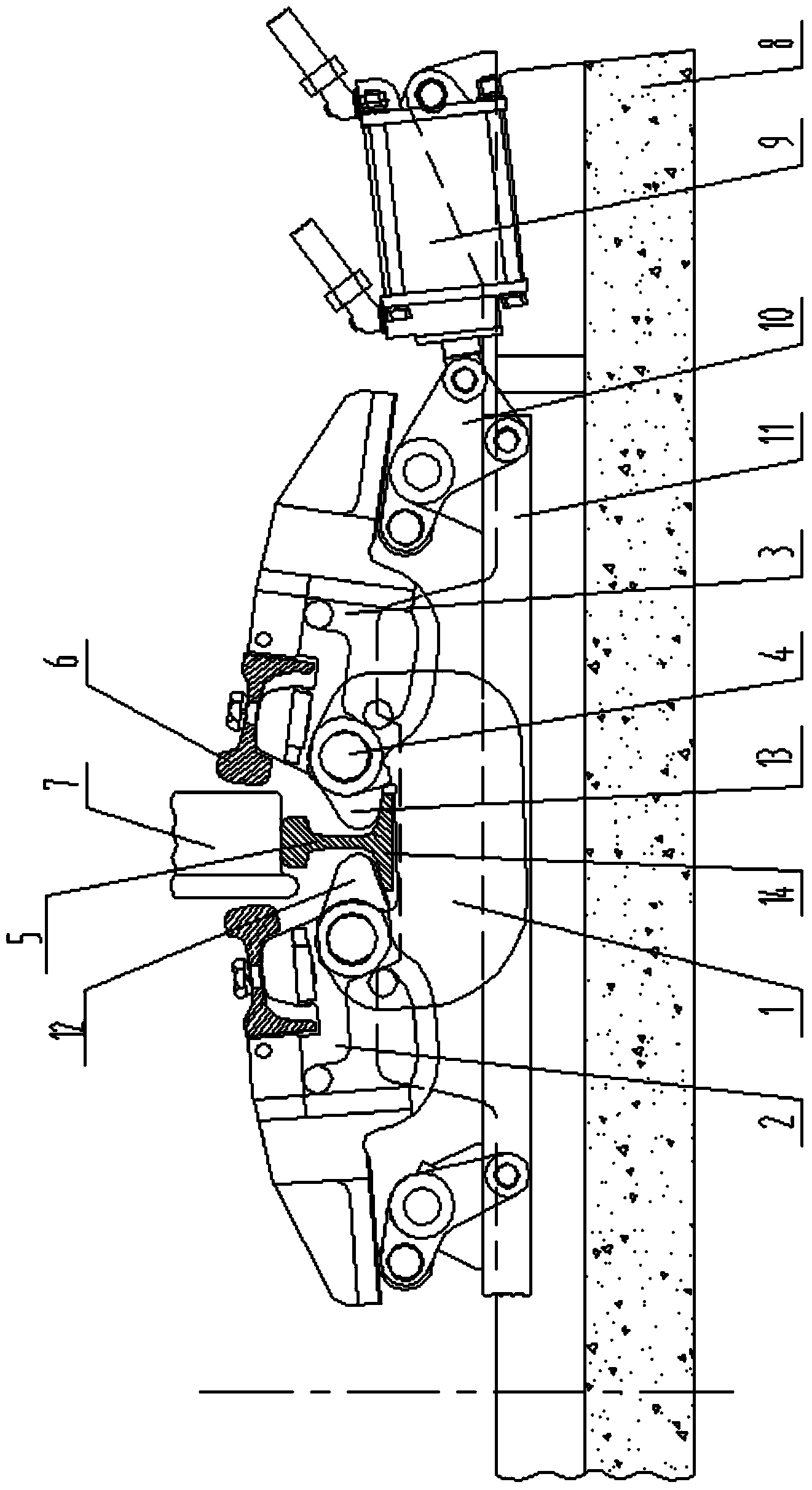

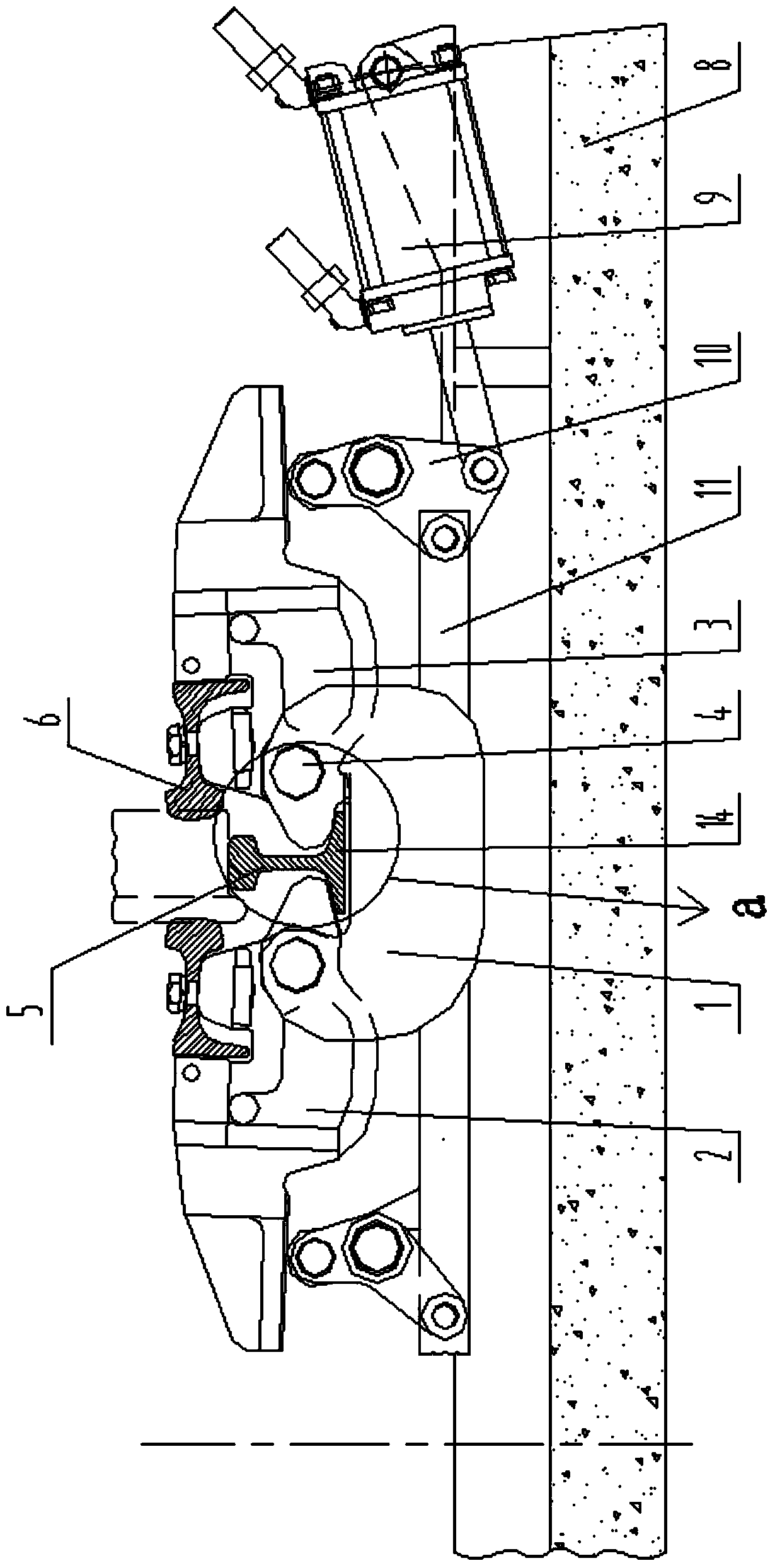

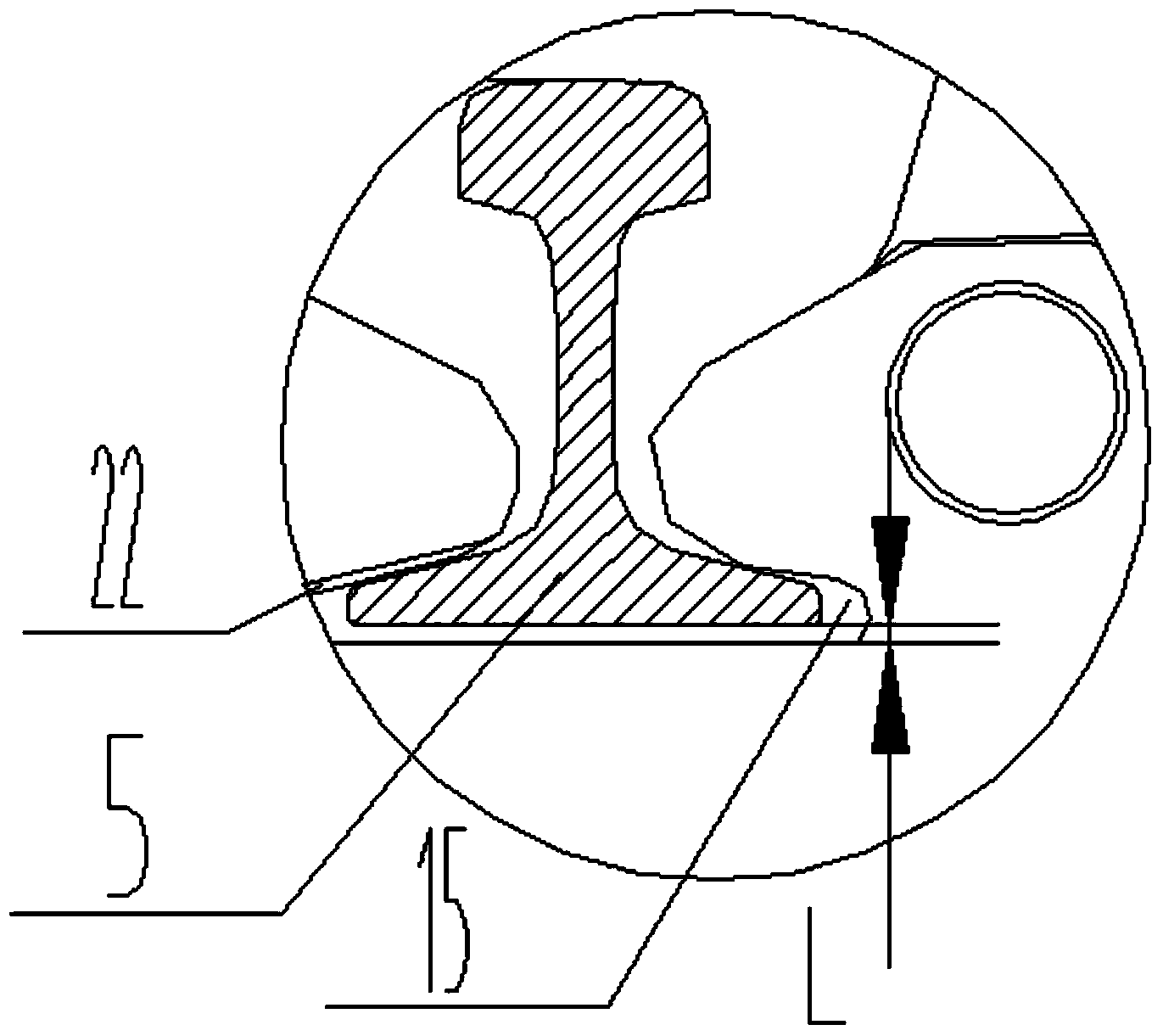

[0023] Such as Figure 1-7 As shown, a vehicle speed reducer with a detachable rail bearing includes a rail bearing 1, an inner brake caliper 2, an outer brake caliper 3 and a bell crank 10, and a 25m long running rail 5 is fixed on a sleeper plate 8. The rail bearing 1 is an asymmetrical, semi-open, detachable bearing. The rail bearing 1 is provided with a rail groove 15 for placing the running rail 5. There are spindle holes 20 on both sides of the rail bearing 1, through which the main shaft 4. The bushing is connected with the brake calipers, a pair of inner brake calipers 2 and outer brake calipers 3 are respectively located on both sides of the running rail 5, and a pair of brake rails 6 are respectively fixed on the brake calipers on both sides. The afterbody of inner brake caliper 2 and outer brake caliper 3 is pressed on the crank th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com