The frame structure of the front part of the frame and its motorcycle

A frame structure and frame technology, which is applied to motorcycle parts and its application fields, can solve the problems of increased management difficulty of manufacturers, many frame states, and reduced production efficiency, so as to improve driving safety, good integrity, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

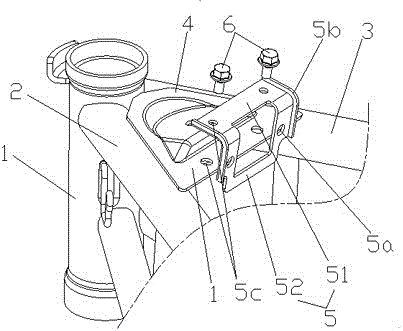

[0015] figure 1 It is a schematic diagram of the structure of the present invention, as shown in the figure: the front frame structure of the vehicle frame of the present invention includes a front riser 1, a left front main beam 2 and a right front main beam 3, and the left front main beam 2 and the right front main beam 3 are parallel It is installed and its front end is connected with the front riser 1, and it also includes a mounting plate I4 for connecting with the fuel tank and a mounting plate II5 for connecting with the secondary air supply valve. The beam 2 and the right front main beam 3 are connected correspondingly, and the installation plate II5 is detachably connected to the installation plate I4; the front main beam is two parallel, which can improve the overall stability and safety of the frame; the left front main beam 2 and the right front The main beam 3 can be either tubular or plate-shaped; the specific shape of the mounting plate I4 can be determined acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com