Control system used for variable-frequency-driving scraper conveyor

A scraper conveyor and control system technology, applied in the direction of conveyor control devices, conveyors, conveyor objects, etc., can solve the problem of the inability to detect the volume and speed of the scraper conveyor, and the inability to adjust the volume of the scraper conveyor, etc. problem, achieve the effect of preventing the car from being crushed and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

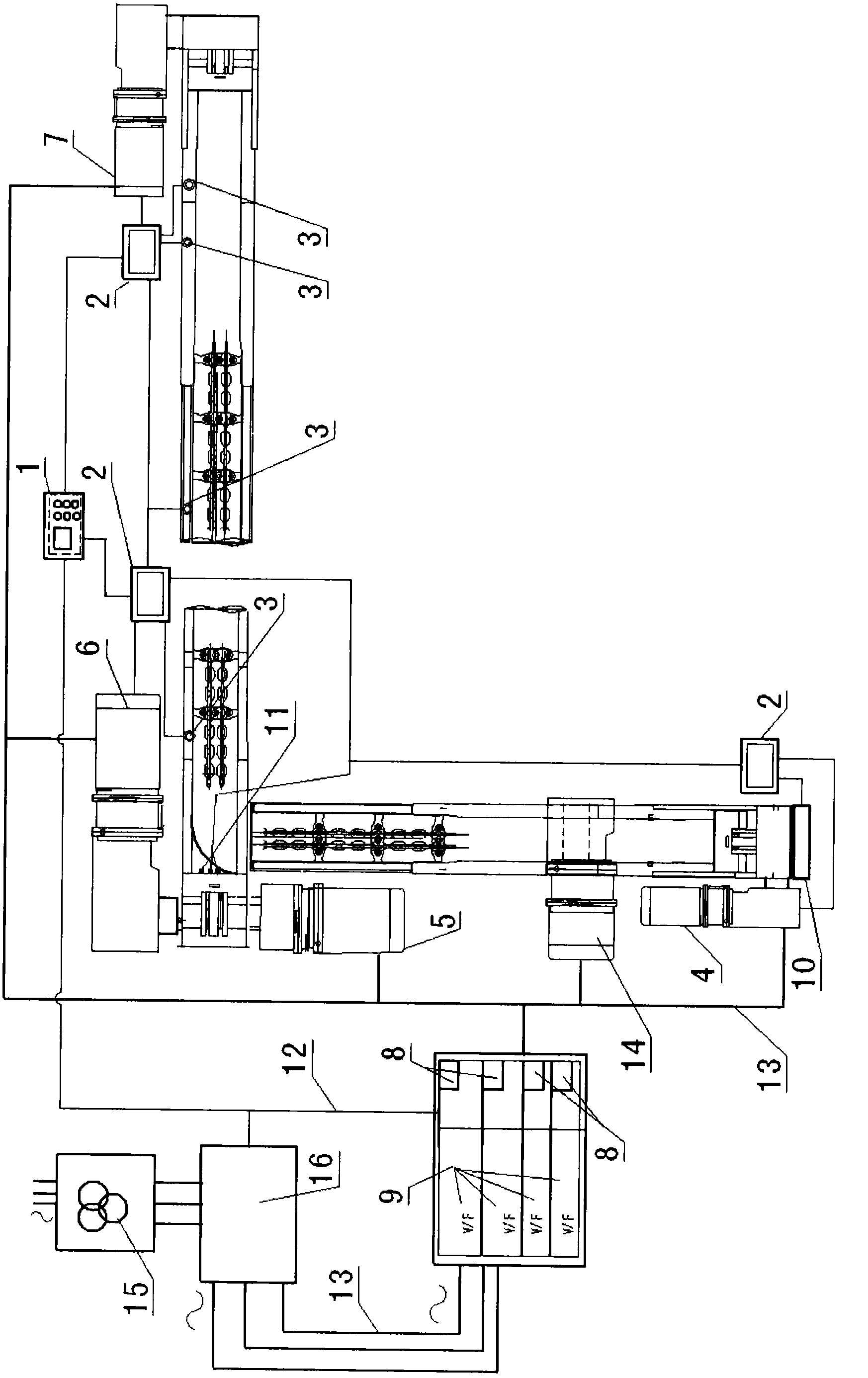

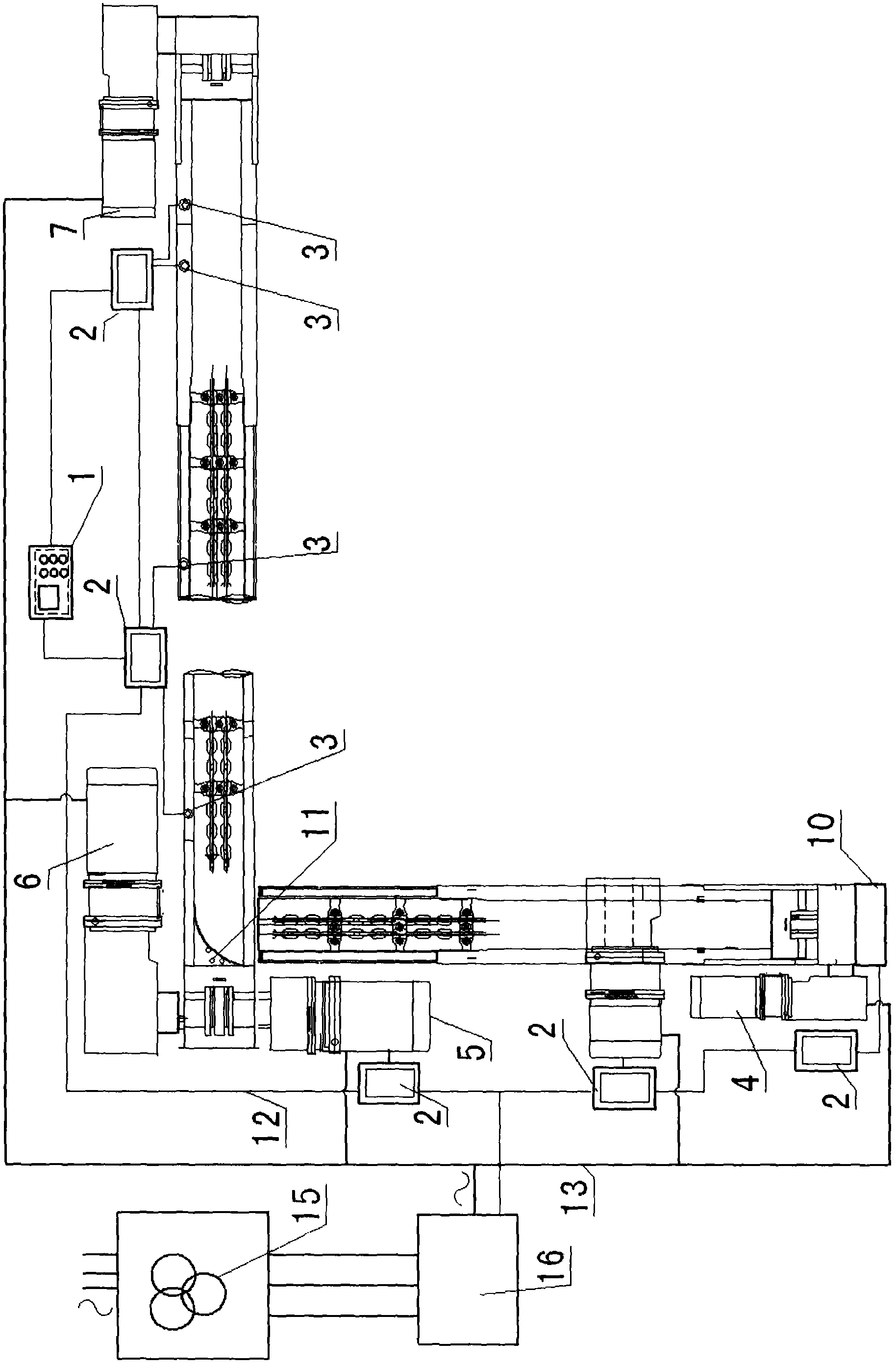

[0020] like figure 1 , figure 2 As shown, in the present invention, the mine explosion-proof frequency converter is used to control the scraper conveyor control system. According to the combination of the frequency converter and the motor, it is divided into a split explosion-proof frequency converter driving the scraper conveyor control system and an integrated explosion-proof frequency converter driving the scraper conveyor. Board conveyor control system.

[0021] like figure 1 , figure 2 As shown, the core controller 1 of the upper computer acquires the signal from the high-voltage explosion-proof combination switch 16, the explosion-proof frequency converter controller unit 8, and the lower computer acquires the signal of the controller 2, and passes the explosion-proof frequency converter controller unit 8 to the explosion-proof frequency converter through the program algorithm. Controlled by the power unit 9, the explosion-proof inverter power unit 9 controls the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com