Magnet brake used for lifting equipment

A technology of electromagnetic brakes and brakes, applied in the direction of hoisting devices, etc., can solve the problems of poor braking effect, poor comfort, incomplete separation of brake pads and brake discs, etc., and achieve good braking effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

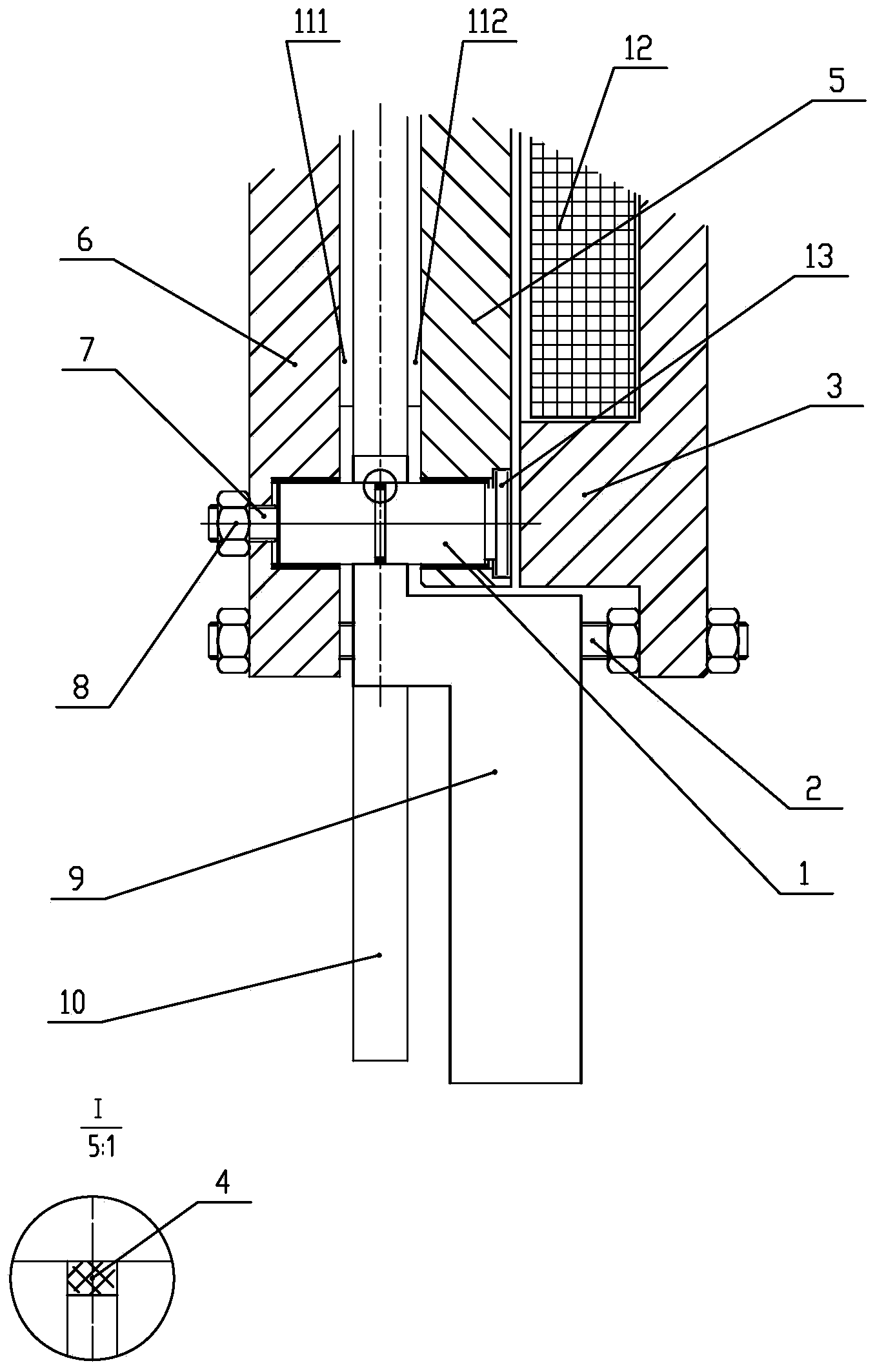

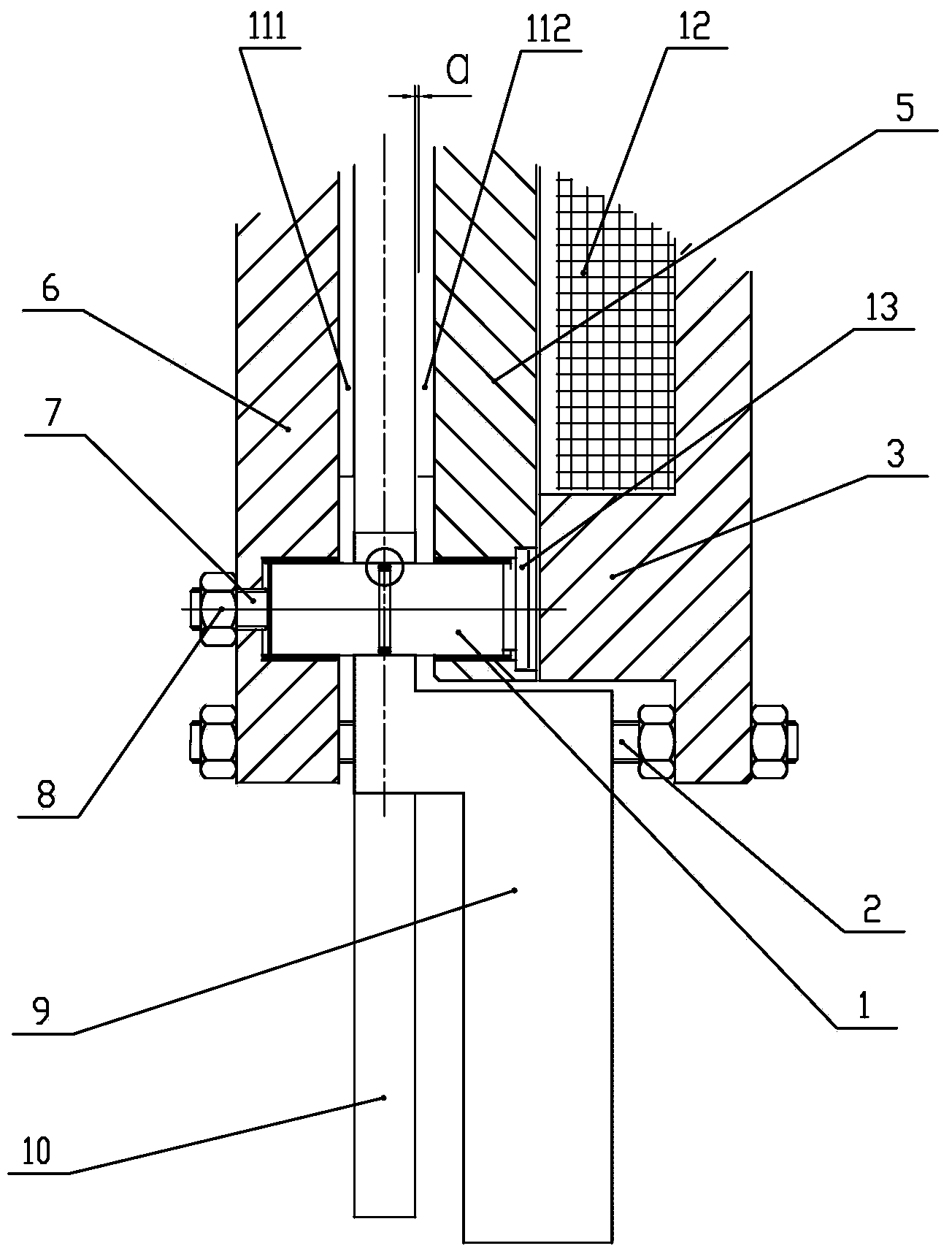

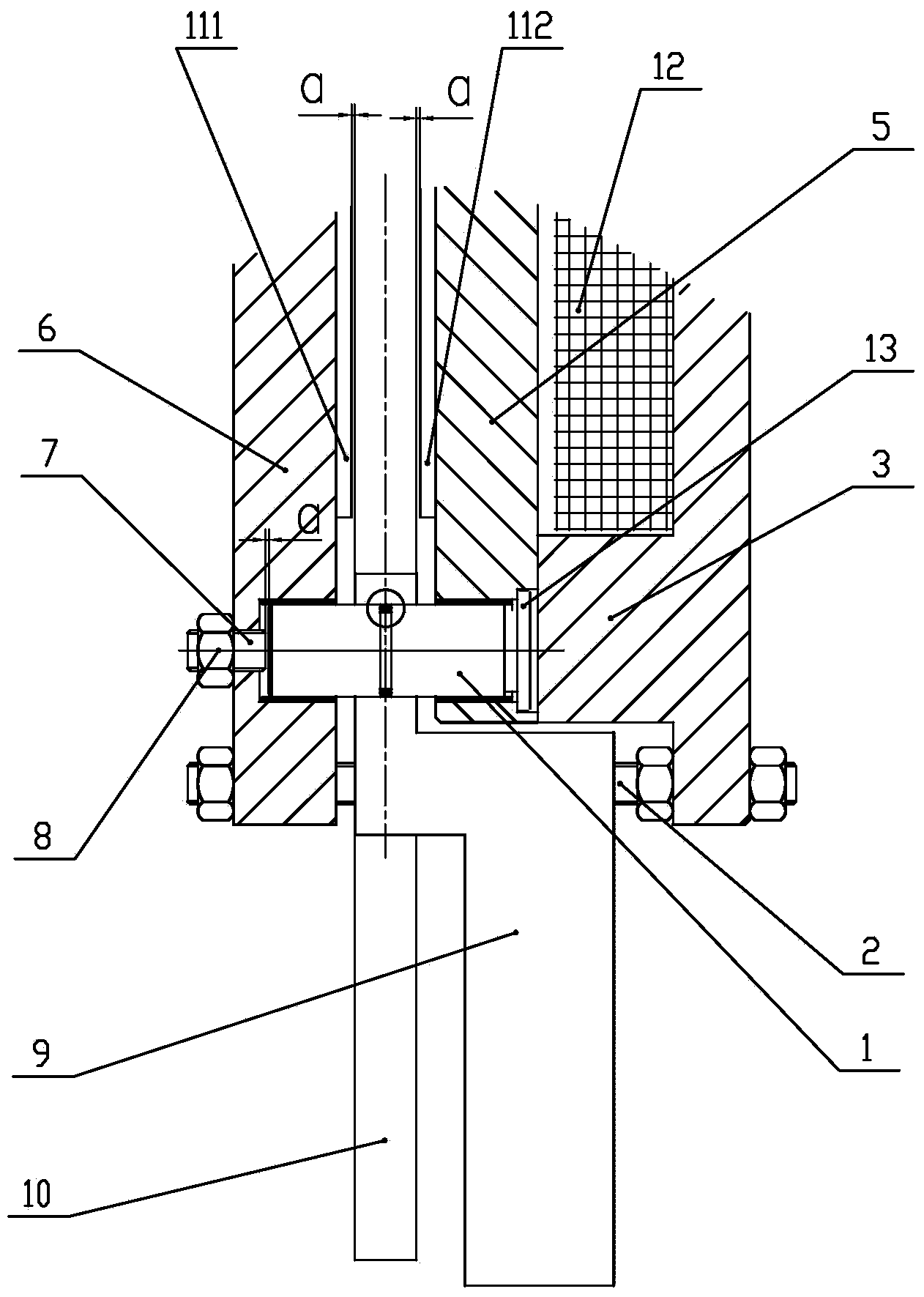

[0014] Such as Figure 1-3 As shown, this electromagnetic brake for lifting equipment includes a brake seat 3, an armature 5, a shoe 6, an electromagnet 12, a brake disc 10, and a brake pad 11. The electromagnet is installed on the brake seat, and the shoe The armature is arranged on the left and right sides of the brake disc. The brake pads include first and second brake pads 111 and 112. The right side of the shoe is provided with a first brake pad 111, and the left side of the armature is provided with a second brake pad 112. And the right side of the armature is adjacent to the electromagnet, the brake disc is installed on the hoisting machine of the hoisting equipment, a pin 1 is provided on the support plate 9 of the hoisting machine, and the left and right parts of the pin are slidably connected to the shoe and the armature. , The right end of the pin is provided with a flange 13, which is in the groove on the right side of the armature. The middle of the pin is covered ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com