A round bar integral walking heating furnace

A heating furnace and round rod technology, which is applied in the field of feeding system to achieve the effect of less heat loss, smooth heating temperature and uniform temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the characteristics and advantages of the present invention clearer, the following description will be made in conjunction with specific embodiments.

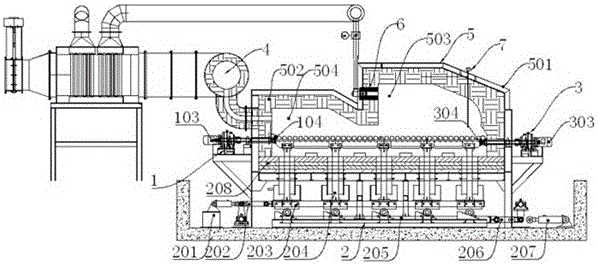

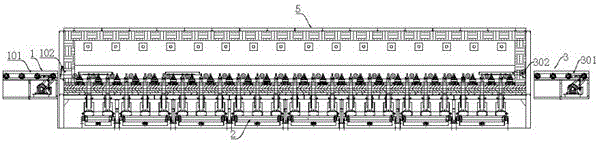

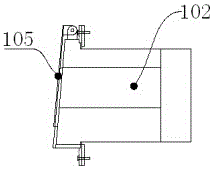

[0022] Such as Figure 1 to Figure 5 As shown, a round rod integral walking heating furnace includes a feeding device 1, a stepping device 2, a discharging device 3, a smoke exhaust system 4, a heat storage chamber 5, a combustion system 6, and a thermocouple 7. The bottom of the hot chamber 5 is provided with a stepping device 2 and a fixed beam 208. The stepping device 2 is composed of a moving beam 204, a translation cylinder 201, a translation linkage mechanism 202, a walking beam 203, a lifting mechanism 205, and a lifting linkage mechanism 206. , lifting cylinder 207, the fixed beam 208 is a multi-layer structure, the heat storage chamber 5 is composed of an aluminum silicate fiber furnace body 502, a combustion chamber 503 and a preheating chamber 504, and the aluminum silicate fiber furnace body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com