Airbag fabric and production method thereof

A production method, fabric technology, applied in the direction of fabric, fabric surface trimming, heating/cooling fabric, etc., able to solve the problems of tensile elongation at break, difference, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

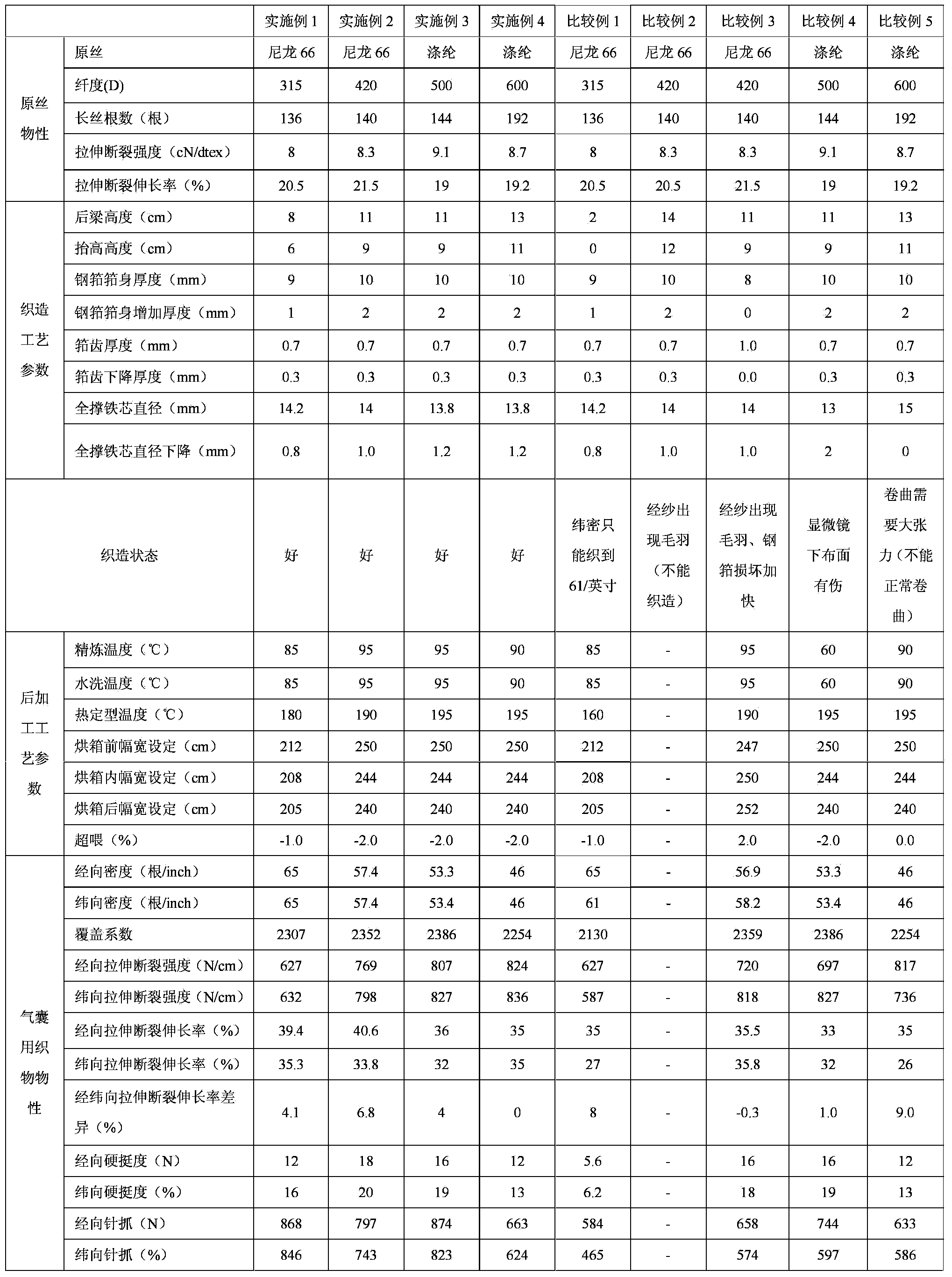

Embodiment 1

[0031] The airbag fabric is made of nylon 66 raw yarn with a total denier of 315D, 136 single filaments, and a circular cross-section. The tensile breaking strength is 8CN / dtex, and the tensile breaking elongation is 20.5%. The loom adopts Picanol optimax-3000 rapier loom, the height of the back beam is 8cm, the thickness of the reed body is 9mm, the thickness of the reed teeth is 0.7mm, the diameter of the full support iron core is 14.2mm, and the opening time is 330° Process conditions After weaving, post-processing is carried out in a scouring and heat-setting integrated machine with a scouring tank temperature of 85°C, a washing tank temperature of 85°C, a heat-setting temperature of 180°C, and a speed of 20 m / min to obtain a warp density of 65. Fabrics with threads / inch and a weft density of 65 threads / inch. The properties of the fabric were evaluated and are shown in Table 1.

Embodiment 2

[0033] The airbag fabric uses nylon 66 raw yarn with a total denier of 420D, 140 single filaments, and a circular cross-section. The tensile breaking strength is 8.3CN / dtex, and the tensile breaking elongation is 21.5%. The loom adopts Picanol optimax-3000 rapier loom, the height of the back beam is 11cm, the thickness of the reed body is 10mm, the thickness of the reed teeth is 0.7mm, the diameter of the full-bracing iron core is 14.0mm, and the opening time is 330° Process Conditions After weaving, post-processing is carried out in a scouring and heat-setting integrated machine with a scouring tank temperature of 95°C, a washing tank temperature of 95°C, a heat-setting temperature of 190°C, and a speed of 18 m / min to obtain a warp density of 57 Fabrics with threads / inch and a weft density of 57 threads / inch. The properties of the fabric were evaluated and are shown in Table 1.

Embodiment 3

[0035]The airbag fabric is made of polyester raw yarn with a total fineness of 500D, 144 single filaments, and a circular cross section. The tensile breaking strength is 9.1CN / dtex, and the tensile breaking elongation is 19.0%. The loom adopts Picanol optimax-3000 rapier loom, the height of the back beam is 11cm, the thickness of the reed body is 10mm, the thickness of the reed teeth is 0.7mm, the diameter of the full-bracing iron core is 13.8mm, and the opening time is 330° Process conditions After weaving, post-processing is carried out in a scouring and heat-setting integrated machine with a scouring tank temperature of 95°C, a washing tank temperature of 95°C, a heat-setting temperature of 195°C, and a speed of 18 m / min to obtain a warp density of 53.5 Fabrics with threads / inch and a weft density of 53.5 threads / inch. The properties of the fabric were evaluated and are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com