Antibiotic-free green efficient broiler compound feed and preparation method thereof

A compound feed and high-efficiency technology, applied in the direction of animal feed, animal feed, and animal feed molding or processing, can solve the problems of high infection rate, mortality rate, high feed-to-meat ratio, and little improvement in gastrointestinal absorption and immunity of broilers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

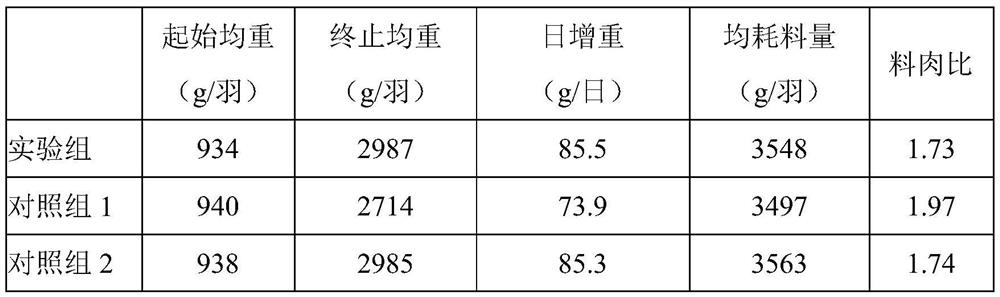

Examples

Embodiment 1

[0048] A method for preparing non-resistant green and high-efficiency broiler compound feed includes the following steps:

[0049] 1) Amino acid: weigh 55% lysine hydrochloride, 99% solid methionine, and threonine, and mix and prepare according to the weight ratio of 5.9:1.9:1.2;

[0050] 2) Compound enzyme preparation: xylanase, cellulase and β-glucanase are mixed in a weight ratio of 1:1:1;

[0051] 3) According to parts by weight, weigh 700 parts of corn, 150 parts of soybean meal, 40 parts of sub-meal, 22 parts of corn gluten meal, 32 parts of cotton meal, 30 parts of soybean oil, 11 parts of stone powder, 6 parts of dicalcium phosphate, and 1 part of salt. Parts, 9 parts of amino acids, 0.7 parts of multi-dimensional broiler, 2 parts of complex trace elements, 0.6 parts of choline chloride, 0.2 parts of complex enzyme preparation, 0.2 parts of high temperature resistant phytase (10000IU), 0.8 parts of cecropin antimicrobial peptide, compound microelement 0.3 part of ecological ...

Embodiment 2

[0058] A method for preparing non-resistant green and high-efficiency broiler compound feed includes the following steps:

[0059] 1) Amino acid: weigh 55% lysine hydrochloride, 99% solid methionine, threonine, and tryptophan, and mix and prepare according to the weight ratio of 6.6:1.9:1.4:0.1;

[0060] 2) Compound enzyme preparation: xylanase, cellulase and β-glucanase are mixed according to the weight ratio of 1:2:1.5;

[0061] 3) In parts by weight, weigh out 575 parts of corn, 200 parts of soybean meal, 60 parts of sub-meal, 43 parts of corn gluten meal, 40 parts of cotton meal, 40 parts of soybean oil, 12 parts of stone powder, 10 parts of calcium hydrogen phosphate, and 2 parts of salt. Parts, 10 parts of amino acids, 0.4 parts of multi-dimensional broiler, 3 parts of complex trace elements, 1.5 parts of choline chloride, 0.5 parts of complex enzyme preparation, 0.5 parts of high temperature resistant phytase (10000IU), 0.5 parts of cecropin antimicrobial peptide, compound mic...

Embodiment 3

[0068] A method for preparing non-resistant green and high-efficiency broiler compound feed includes the following steps:

[0069] 1) Amino acid: weigh 55% lysine sulfate, 99% solid methionine, and threonine, and mix and prepare according to the weight ratio of 5.5:2.0:1.5;

[0070] 2) Compound enzyme preparation: xylanase, cellulase and β-glucanase are mixed according to the weight ratio of 1:2:1.5;

[0071] 3) In parts by weight, weigh out 460 parts of corn, 245 parts of soybean meal, 80 parts of sub-meal, 70 parts of corn gluten meal, 50 parts of cotton meal, 45 parts of soybean oil, 13 parts of stone powder, 13 parts of calcium hydrogen phosphate, and 3 parts of salt. Parts, 11 parts of amino acids, 0.2 parts of broiler multi-dimensional, 4 parts of complex trace elements, 1.9 parts of choline chloride, 0.8 parts of complex enzyme preparation, 0.8 parts of high temperature resistant phytase (10000IU), 0.3 parts of cecropin antimicrobial peptide, compound microelement 1.0 part of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com