Push type ground sweeper

A technology for sweeping vehicles and leveling, applied in the field of sweeping vehicles, can solve the problems of dust pollution, inability to reach small places, slow manual cleaning, etc., and achieve the effects of reducing heavy labor, reducing dust flying, and having a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

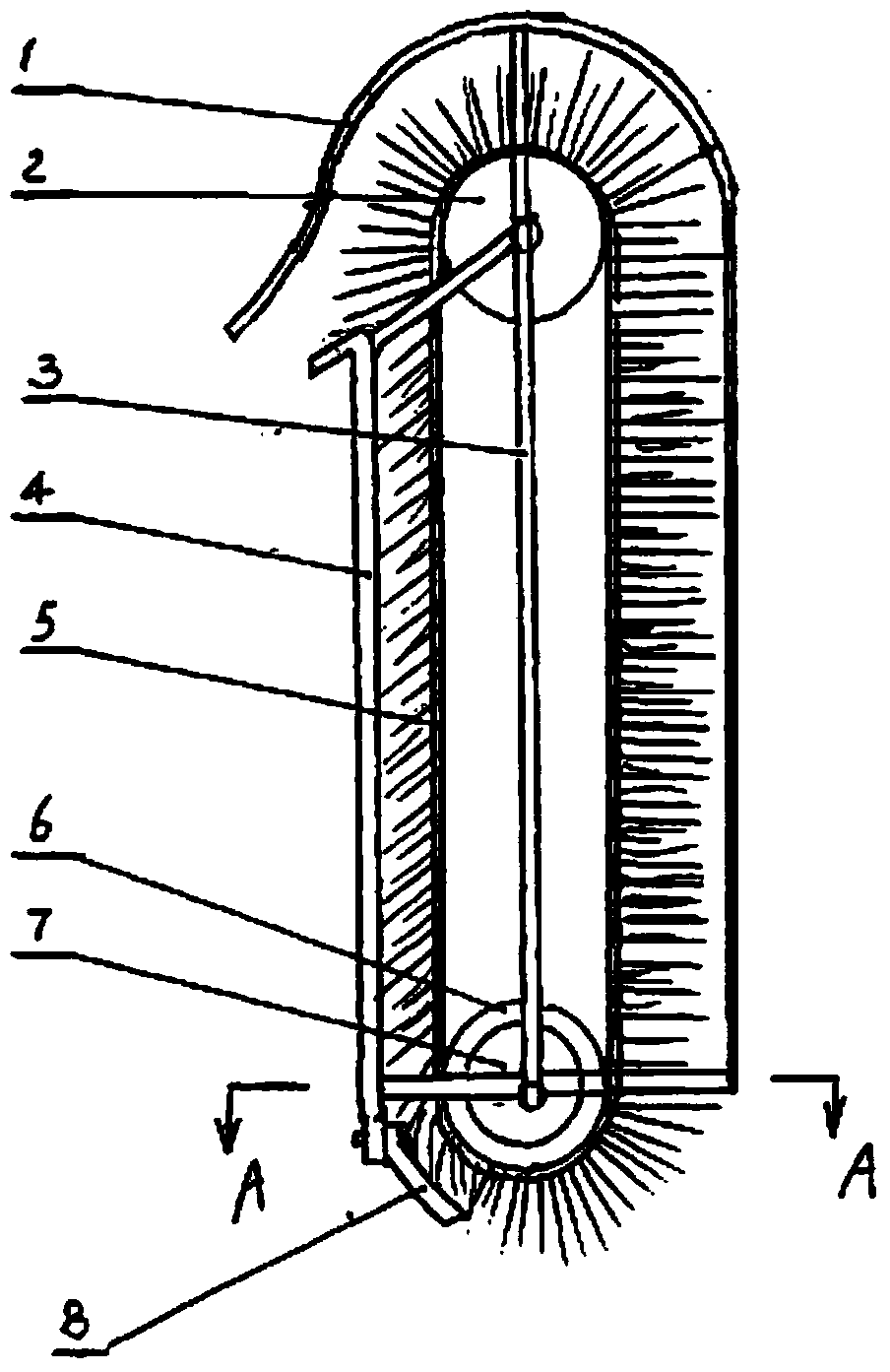

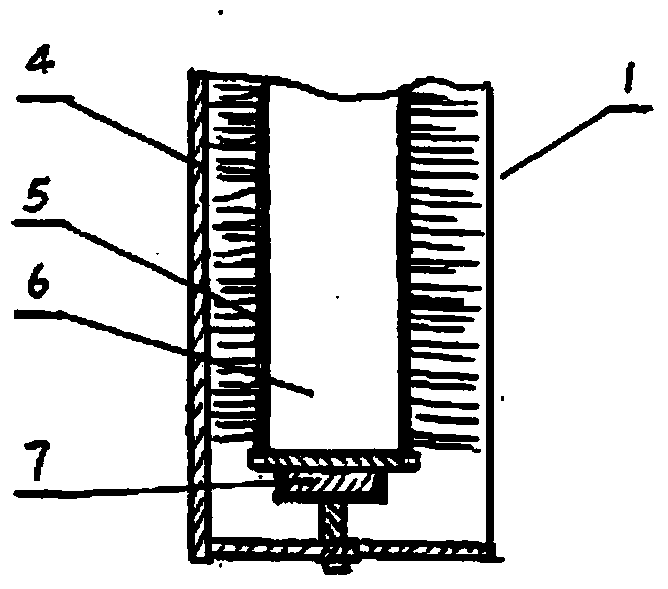

[0009] Below in conjunction with accompanying drawing, the hand pushes the sweeping vehicle for leveling the ground and is further described for implementation.

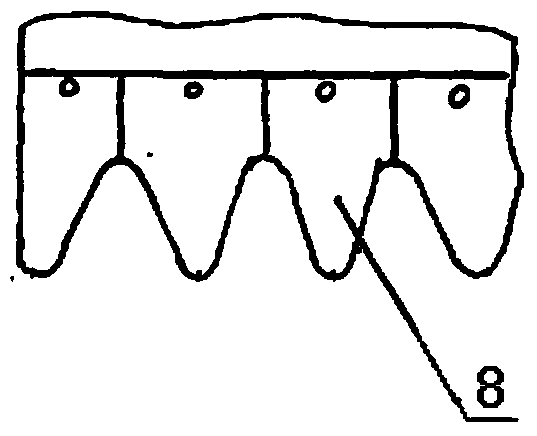

[0010] figure 1 , figure 2 , image 3 It is a schematic diagram of a conduction sweeping device used on a push-flat sweeper. It is installed on the upper end of the bracket (3) with the upper roller (2), and the lower end of the bracket (3) is installed with the lower roller (6), and the upper brush strip transfer belt (5) is wound on the two rollers, and they are connected together . The left end of the lower turning roller (6) is affixed with the upper passive transmission gear (7); in the front of the transfer belt (5) ( figure 1 The right side) is connected to a slanted slide (4) through the bracket (3), and the slanted slide (4) is tightly attached to the brush bar so that it has a certain scraping thrust; the top of the slanted slide (4) is lower than the upper roller (2 ) below the center section of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com