Inflating and exhausting connector used for oil containment boom pontoon for recovering overflowed oil on sea surface

A technology for oil spills and oil booms on the sea surface, which is used in the cleaning of open water surfaces, general water supply conservation, construction, etc., can solve the problems of easy air leakage and weak air tightness of equipment, and achieves good sealing effect and weather resistance. The effect of excellent aging performance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0024] It should be noted that this embodiment is implemented on the premise of the technical solution of the present invention, and the detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

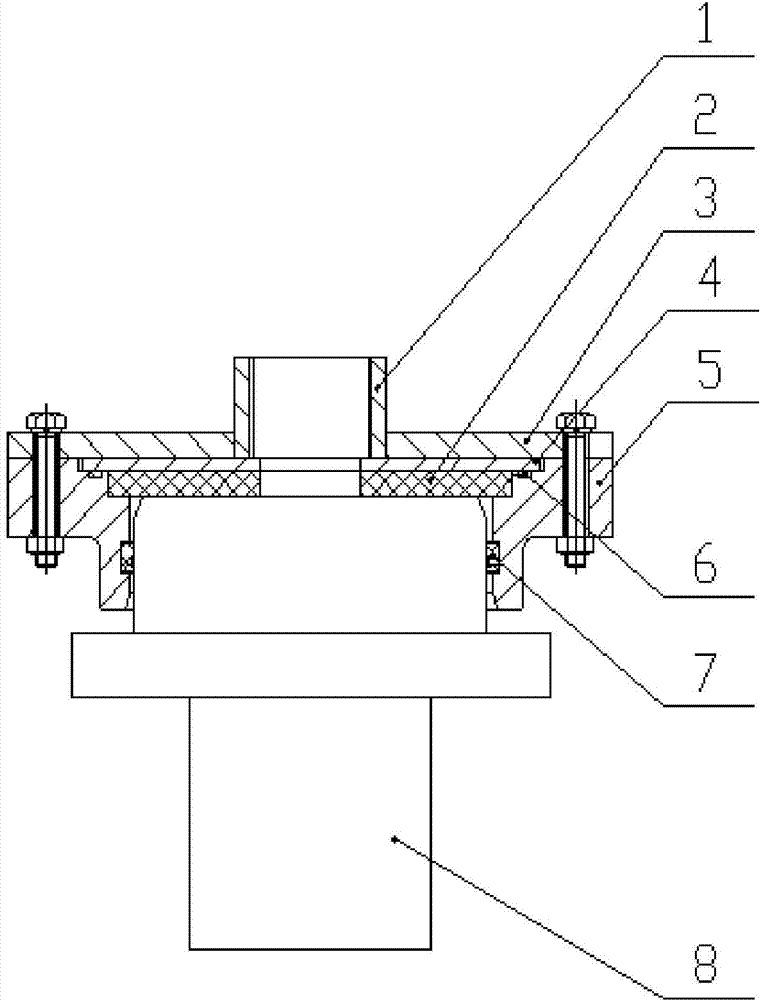

[0025] Such as figure 1 As shown, the charging and exhausting interface for the buoy of the oil boom buoy for oil spill recovery on the sea surface in this embodiment includes an air intake pipe 1, a rubber pad 2, a ventilation frame 3, a backing plate 4, an air nozzle pressure plate 5, and an O-ring 6 And sealing ring 7; Its air intake pipe 1 is welded on the outside of ventilation frame 3, and backing plate 4 is welded on the inside of ventilation frame;

[0026] The ventilation frame 3 and the valve pressure plate 5 are connected together by bolts;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com