Automatic disassembly type pole standing side rope retaining ring and method for standing pole with same

A side rope and wire rod technology, which is applied in the processing of building materials, building types, buildings, etc., can solve the problems of increased labor intensity, reduced work efficiency, and unfavorable line rod correction, so as to reduce labor intensity and improve labor efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following is a further description of the self-detachable vertical rod side rope buckle sleeve proposed by the present invention and the method of using the buckle sleeve to erect the pole in conjunction with the accompanying drawings.

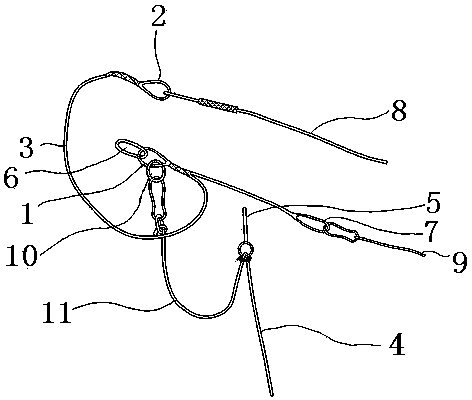

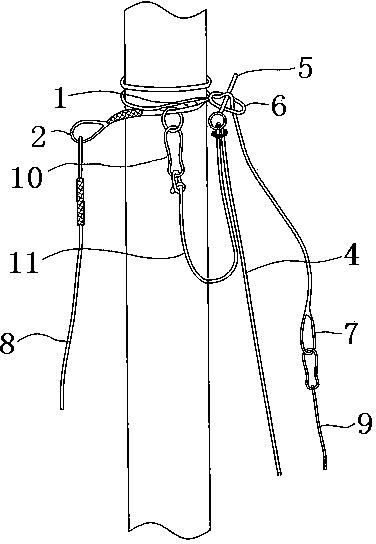

[0024] Such as figure 1 and figure 2 Shown is a schematic diagram of the structure of the self-detachable pole side rope buckle sleeve. The self-detachable vertical rod side rope buckle cover includes an oil silk rope body 3 with a first oil silk rope clip 1 and a second oil silk rope clip 2 at both ends and a pin shaft 5 with a pin shaft stay rope 4. A snap ring 6 is arranged on the first oil rope clip 1, a third oil silk rope clip 7 is arranged on the oil silk rope body 3 at one end of the first oil silk rope clip 1, and a third oil silk rope clip 7 is arranged on the second oil silk rope clip 2 and the second oil silk rope clip 2. Have the first side rope 8 and the second side rope 9 in the three oil silk rope clips 7.

[002...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap