Cooling unit of direct air-cooling steam condenser

A technology for air-cooled condensers and heat dissipation units, which is applied to steam/steam condensers, lighting and heating equipment, etc. It can solve the problems of increased power consumption of cooling fans, unfavorable equipment installation and economical operation, and insufficient space utilization of air-cooled units.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

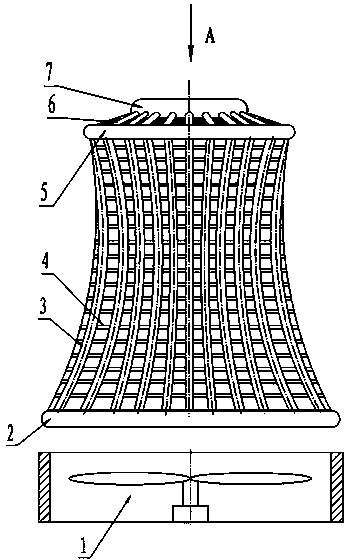

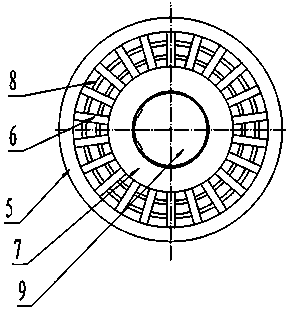

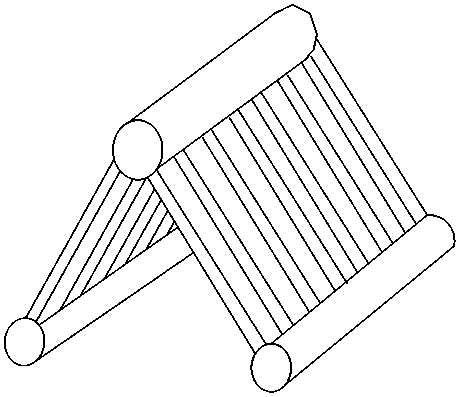

[0017] see figure 1 , figure 2 , the present invention consists of an air-cooling unit body and a fan 1 located at the lower part of the air-cooling unit body. The body of the air-cooling heat dissipation unit includes a main heat exchange surface and a top heat exchange surface, and the top heat exchange surface is located on top of the main heat exchange surface. The steam first enters the top heat exchange surface for preliminary heat exchange and cooling, and then the steam after preliminary heat exchange enters the main heat exchange surface for heat exchange. The main heat exchange surface is composed of a group of main heat exchange tubes 3 whose axes are hyperbolic. Condensed water recovery pipe 2, the central axis of the main heat exchange surface is in line with the axis of the fan. The top heat exchange surface includes circular steam distribution pipes 7 and a set of top heat exchange pipes 6. The steam distribution pipes are located in the middle of the top h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com