Method of Measuring Air Specific Heat Capacity Ratio by Piston Vibration in Cylinder

A vibration measurement, specific heat capacity ratio technology, applied in the direction of analyzing materials, instruments, etc., can solve problems such as difficulty in realization, rotational uncertainty, uneven surface, etc., and achieve the effect of low cost, simple structure, and rigorous experimental principle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

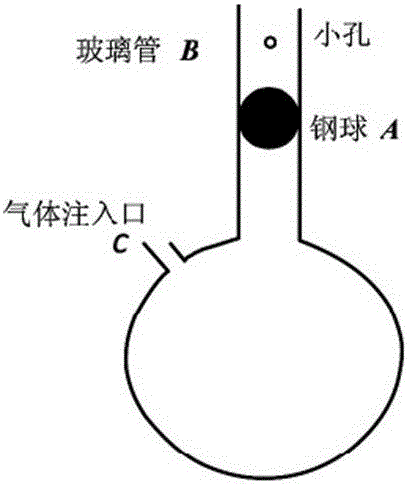

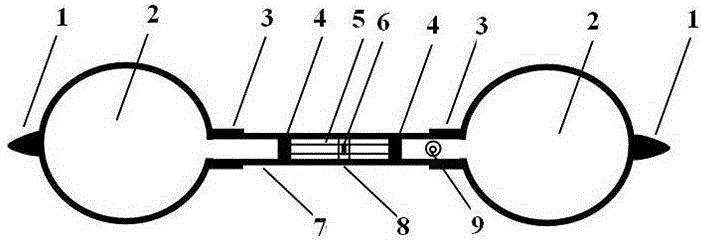

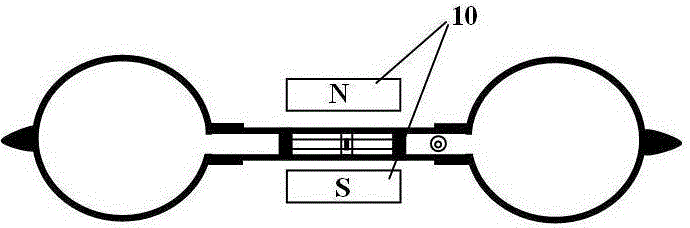

Embodiment Construction

[0013] A cylinder 7 made of transparent hard material (hard transparent material is glass, hard plastic, etc., which can withstand pressure, and the deformation caused by pressure is relatively small and negligible) has external threads at both ends, and is connected by threads. 3 connect the gas containers 2 symmetrically at both ends of the cylinder 7 (the internal volumes of the gas containers 2 on both sides are equal, in other words, the internal volumes are the same, and from the perspective of ease of use and replacement, all gas containers 2 produced by the manufacturer are the same. are the same specifications), the gas container 2 and the cylinder 7 are connected by thread 3, and the sealing is realized by the sealing gasket of the prior art; there is an air hole on the outside of the gas container 2, and the air hole is sealed by the sealing cap 1, and the sealing is the existing one. If available, it can be common nuts, threads, gaskets, or other sealing methods; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com