Fire-proof soft-ceramic cable

A soft ceramic and refractory technology, applied in the field of wire and cable, can solve the problems of excellent cable construction, poor fire resistance, inconvenience, etc., and achieve the effect of high production efficiency, good fire resistance and good flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

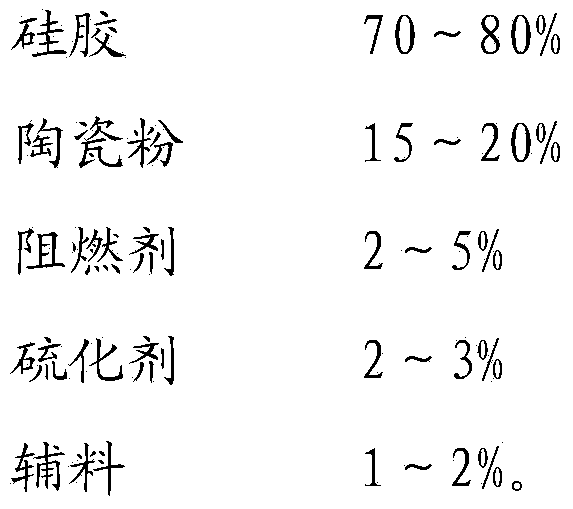

Method used

Image

Examples

Embodiment 1

[0013] First, add 20% of the mixture of clay powder and silica powder, 5% of flame retardant, 1% of antioxidant and 1% of sintering aid into the mixer according to the weight percentage, and then put it into the internal mixer At the same time, add 70% of silica gel and 3% of vulcanizing agent, banbury and coat the cable conductor, and vulcanize at 150-300°C to obtain a refractory soft ceramic cable.

[0014] After the product is stabilized for 2 hours, put it into the aging box, keep the temperature at minus 40°C for 2 hours, the low-temperature tensile elongation at break is 280%, and it will not crack when bent at low temperature; at 200°C for 2 hours, the high-temperature tensile elongation at break is 350% %, fully meet the design requirements.

[0015] After the product is stabilized for 2 hours, it is baked at 500°C for 2 hours, the material changes from soft to hard, and the insulating layer is completely ceramicized.

[0016] After 2 hours of stabilization, the produ...

Embodiment 2

[0018] First, add 15% of the mixture of feldspar powder and silica powder, 2% of flame retardant, and 1% of sintering aid into the mixer according to the weight percentage, and then put it into the internal mixer, and add 80% of silica gel at the same time After banburying with 2% vulcanizing agent, it is coated on the cable conductor and vulcanized at 150-300°C to obtain a refractory soft ceramic cable.

[0019] After the product is stabilized for 2 hours, put it into the aging box, keep the temperature at minus 40°C for 2 hours, the low-temperature tensile elongation at break is 280%, and it will not crack when bent at low temperature; at 200°C for 2 hours, the high-temperature tensile elongation at break is 350% %, fully meet the design requirements.

[0020] After the product is stabilized for 2 hours, it is baked at 500°C for 2 hours, the material changes from soft to hard, and the insulating layer is completely ceramicized.

[0021] After 2 hours of stabilization, the p...

Embodiment 3

[0023] First, add 18% of silica powder, 5% of flame retardant, and 2% of sintering aid into the mixer according to the weight percentage, stir evenly, and then put it into the internal mixer. At the same time, add 73% of silica gel and 2% of vulcanization Agents are mixed and coated on the cable conductor, and vulcanized at 150-300°C.

[0024] After the product is stabilized for 2 hours, put it into the aging box, keep the temperature at minus 40°C for 2 hours, the low-temperature tensile elongation at break is 280%, and it will not crack when bent at low temperature; at 200°C for 2 hours, the high-temperature tensile elongation at break is 350% %, fully meet the design requirements.

[0025] After the product is stabilized for 2 hours, it is baked at 500°C for 2 hours, the material changes from soft to hard, and the insulating layer is completely ceramicized.

[0026] After 2 hours of stabilization, the product burns in bundles. At a flame temperature of 800°C and a voltage ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com