High-strength commutator

A commutator, high-strength technology, used in current collectors, rotary current collectors, electrical components, etc., can solve the problem of enlarged legs, reduced space for commutator body materials, and high rejection rate of commutator products. problems, to achieve the effect of improving mechanical properties, strengthening bonding strength, and structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

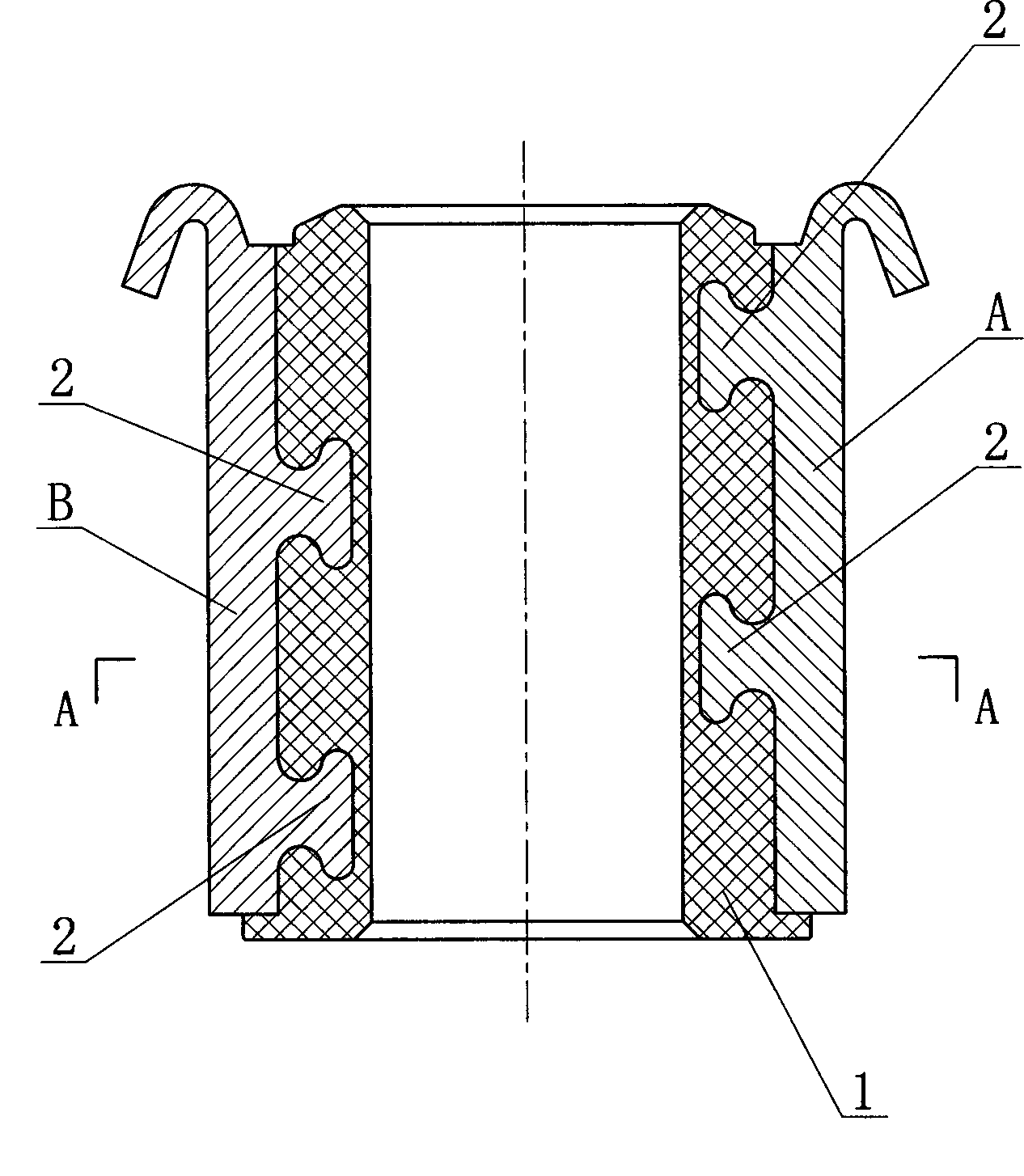

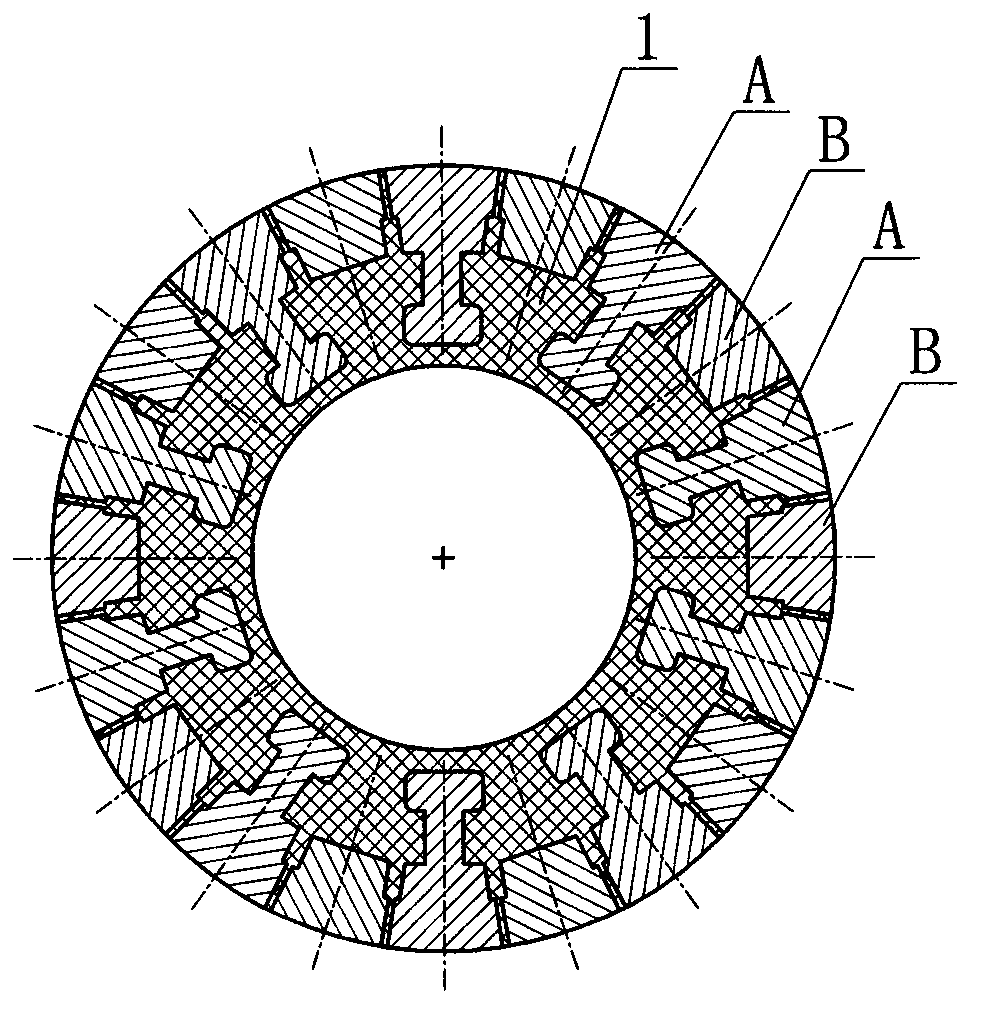

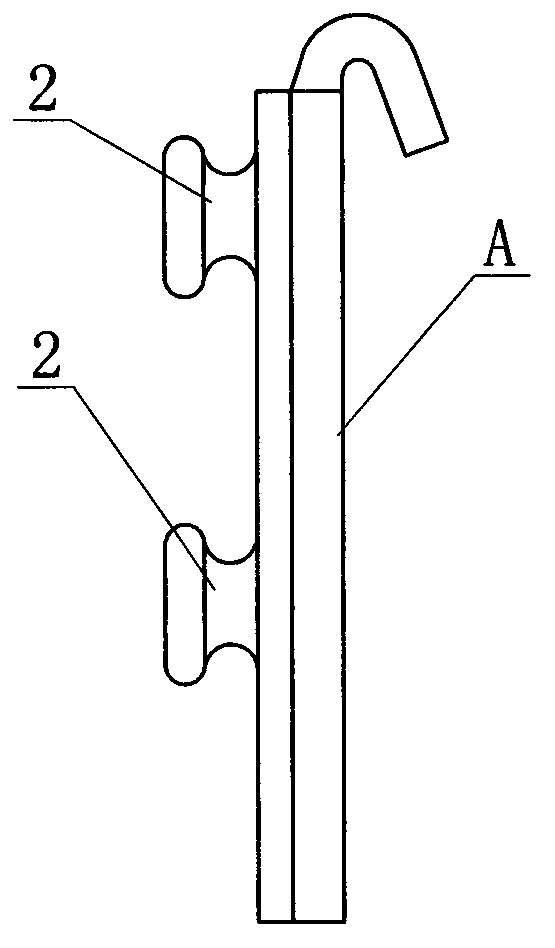

[0015] The accompanying drawings show the technical solution of the present invention and its embodiments, and the relevant details and working principles of the embodiments will be further described below in conjunction with the accompanying drawings.

[0016] As shown in the figure, the high-strength commutator of the present invention includes commutation copper sheets uniformly arranged on the outer circumference of the commutator body 1, and the commutation copper sheets are injection molded together with the commutator body 1, The inner surface of the reversing copper sheet is provided with a piece of foot 2 implanted in the commutator body 1 and firmly combined with the commutator body 1, and the piece of foot 2 is provided with multiple pieces up and down along the height direction of the reversing copper piece. The legs 2 of adjacent commutation copper sheets are staggered in the height direction of the commutation copper sheets and do not interfere with each other. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com