Multi-motor synchronization control system

A synchronous control and multi-motor technology, applied in the direction of controlling multiple AC motors, can solve the problems of data loss and distortion increase, complex connection, synchronous control failure, etc., to reduce the number of controllers, reduce the number of connections, and improve reliability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

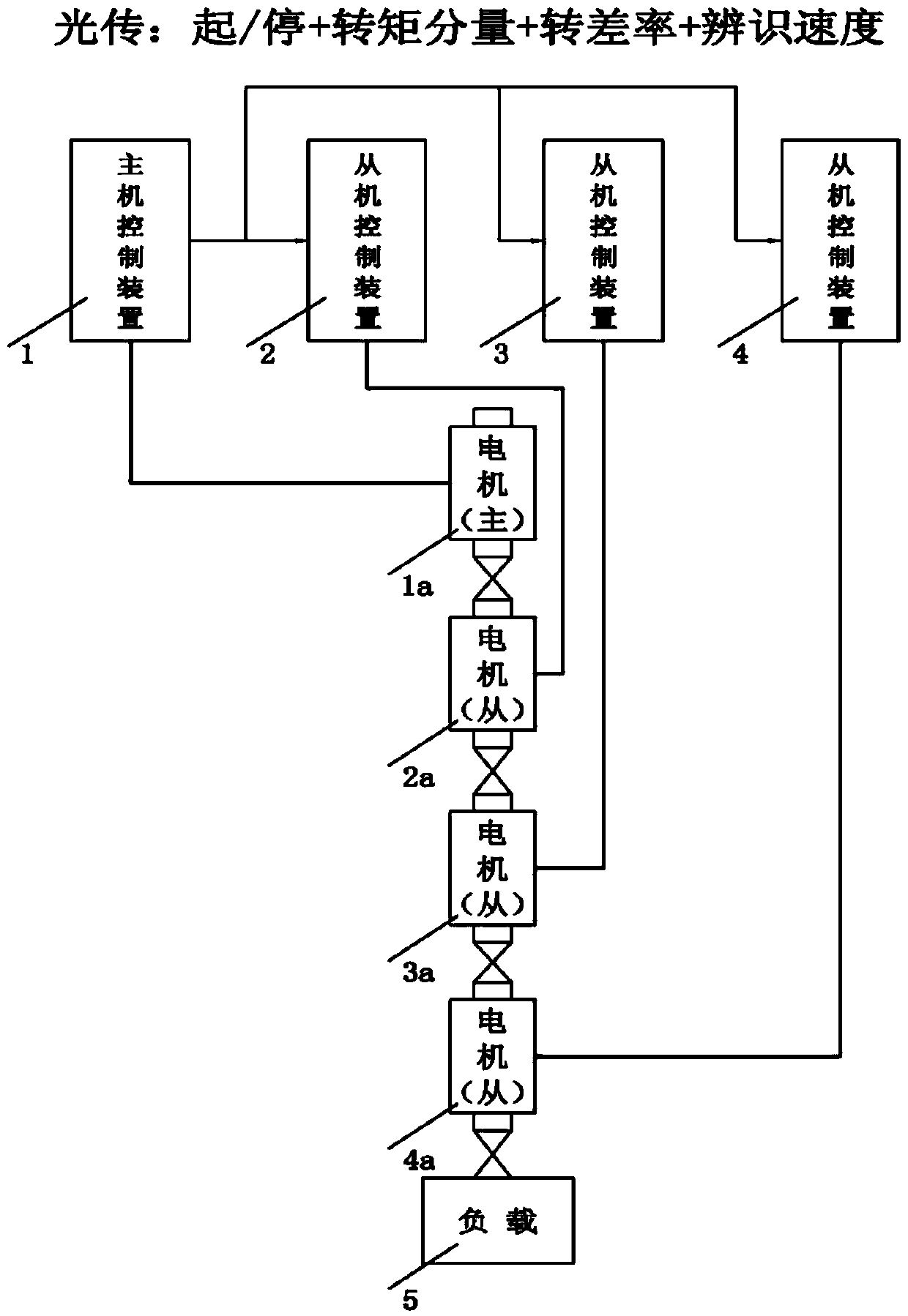

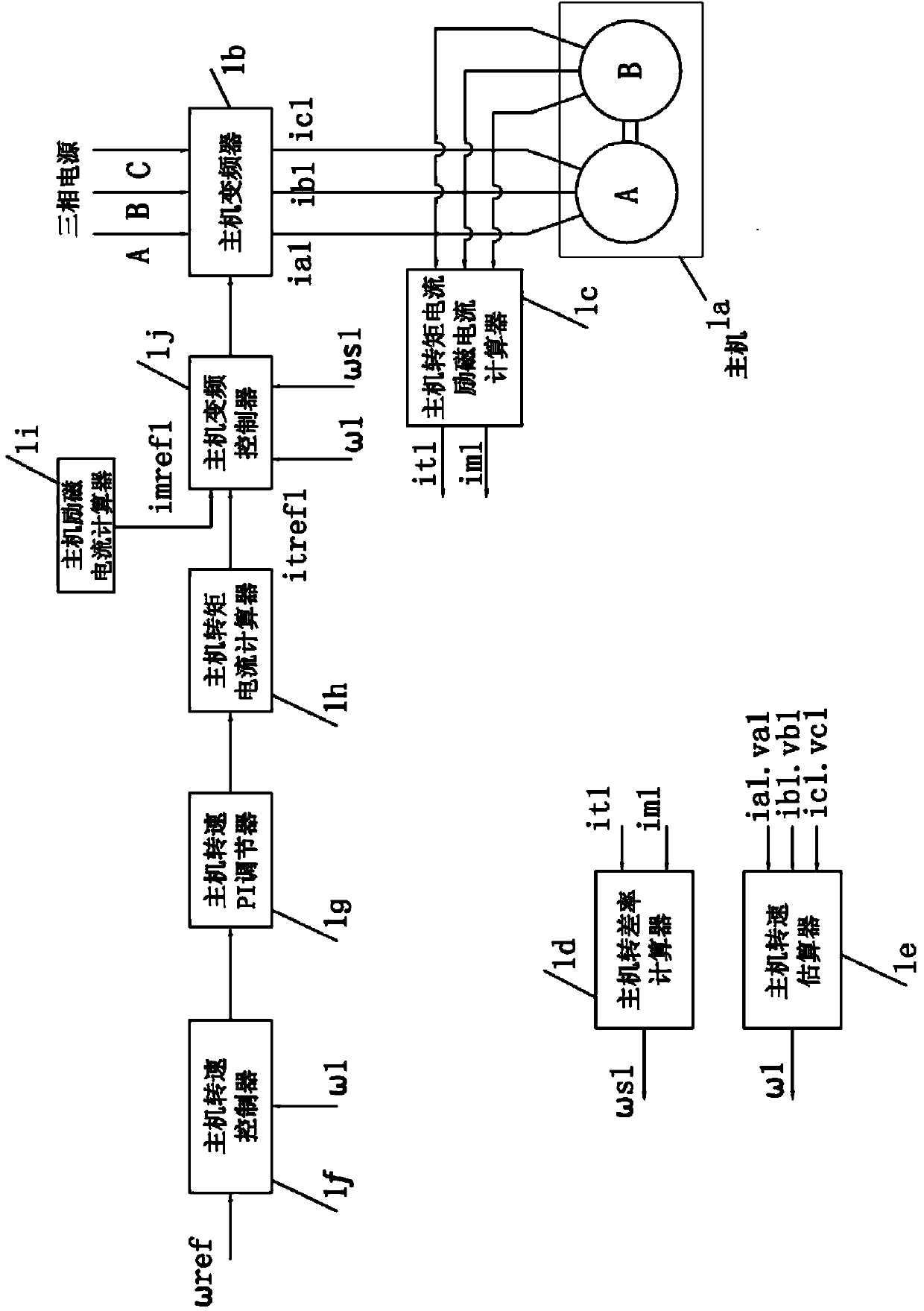

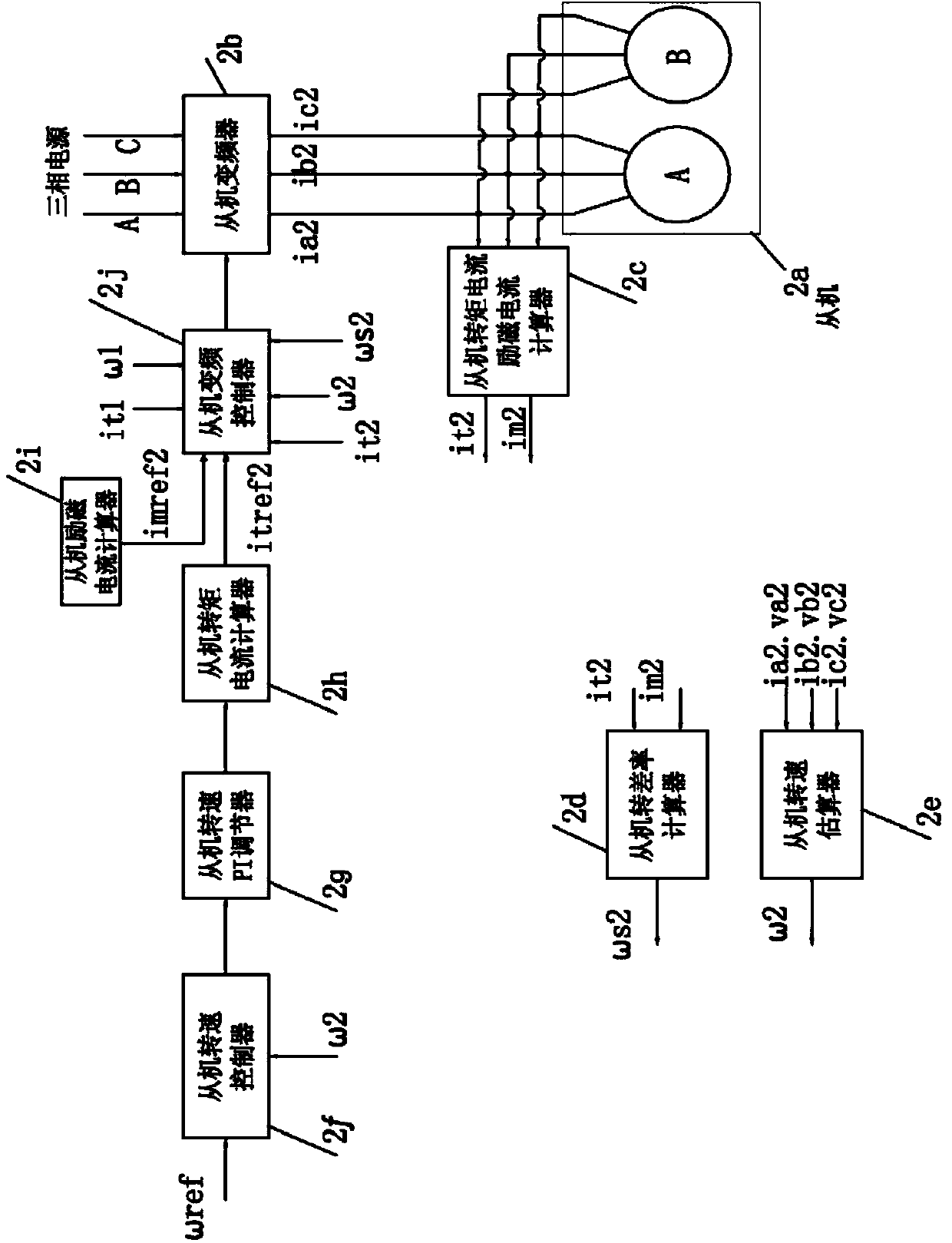

[0013] In this embodiment, if figure 1 As shown, the motor is composed of a master machine 1a, a slave machine 2a, a slave machine 3a, and a slave machine 4a. The output shafts of the master machine 1a, the slave machine 2a, the slave machine 3a, and the slave machine 4a are flexibly connected to each other. The master 1a, the slave 2a, the slave 3a, and the slave 4a are controlled by the master control device 1, the slave control device 2, the slave control device 3, and the slave control device 4, respectively. Host 1a as figure 2 The motor unit shown is composed of two motors A and B. The terminals of motors A and B are connected in parallel to the host control device 1, and the motor shafts of motors A and B are rigidly connected. The slave 2a is the same as the master 1a image 3 The motor unit shown is composed of two motors A and B. The terminals of the two motors A and B are connected in parallel and then connected to the slave control device 2. The motor shafts of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com