Rail switch having a main track and a branch track

A technology of main rails and guide rails, which is applied in roads, tracks, laboratory appliances, etc., and can solve the problems of lower stability of basic rails

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

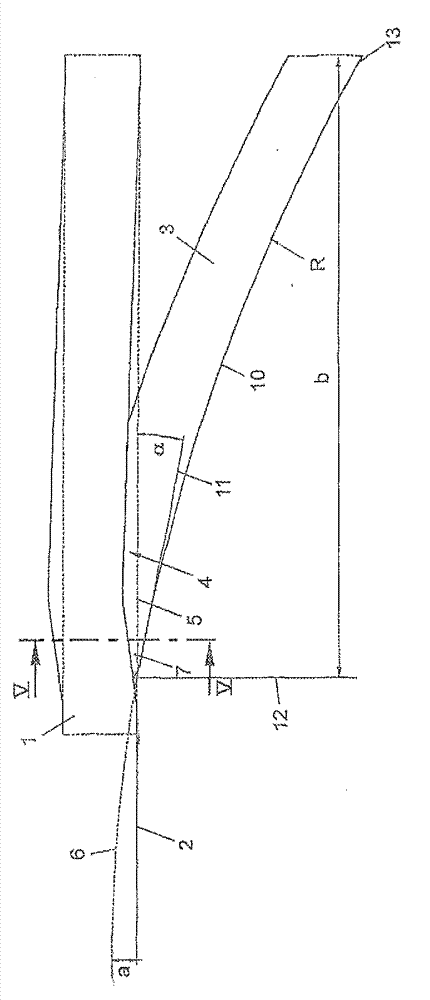

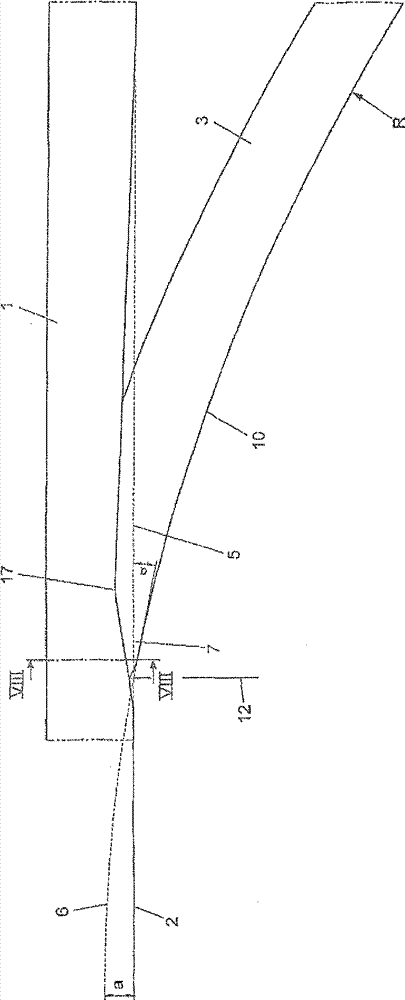

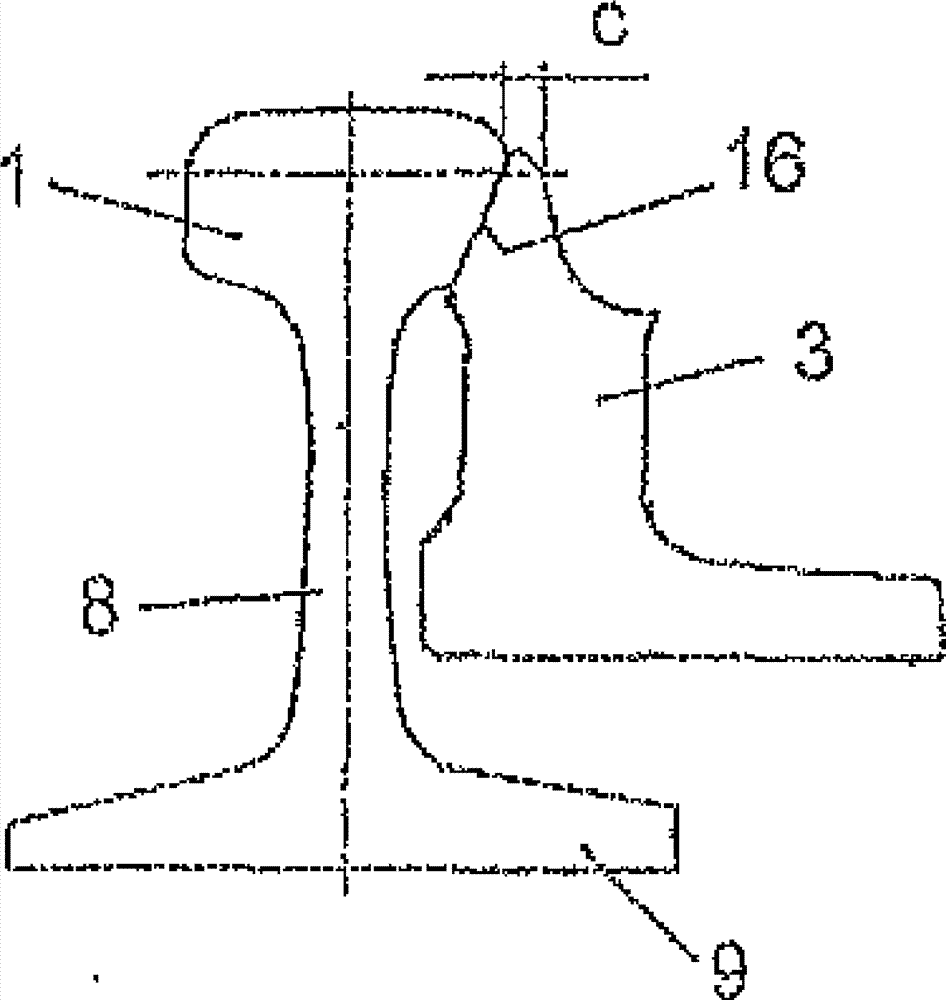

[0018] exist figure 1 Among them, 1 is used to represent the straight basic rail of the guide rail switch, and its running edge is represented by 2. The basic rail 1 basically has a straight guide rail course and accordingly has a straight running edge 2 . Generally speaking, the running edge of the guide rail is produced at the widest point of the guide rail head, which is measured at a predefined or standard-determined vertical distance from the running upper edge. Usually, the width of the base rail head is measured here at a vertical distance of 10 to 20 mm, in particular 14 mm, from the upper running edge.

[0019] In the contiguous region of the switch rail 3 , the base rail 1 is offset from its straight course so that it has a projection 4 , whereby the running edge 2 also acquires a course in this region that deviates from the imaginary continuous straight course 5 . . In this case, the guide rail profile remains completely in the area of the projection 4 , apart ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com