Flowmeter pipeline dredging device

A flow tube and metering tube technology, applied in the field of flowmeter pipeline dredging devices, can solve the problems such as difficulty in dredging the U-shaped flow tube, inability to meet the cleanliness requirements of mass flowmeters, etc., and achieve the effect of convenient cleaning and smooth circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment the technical solution of the present invention is further described:

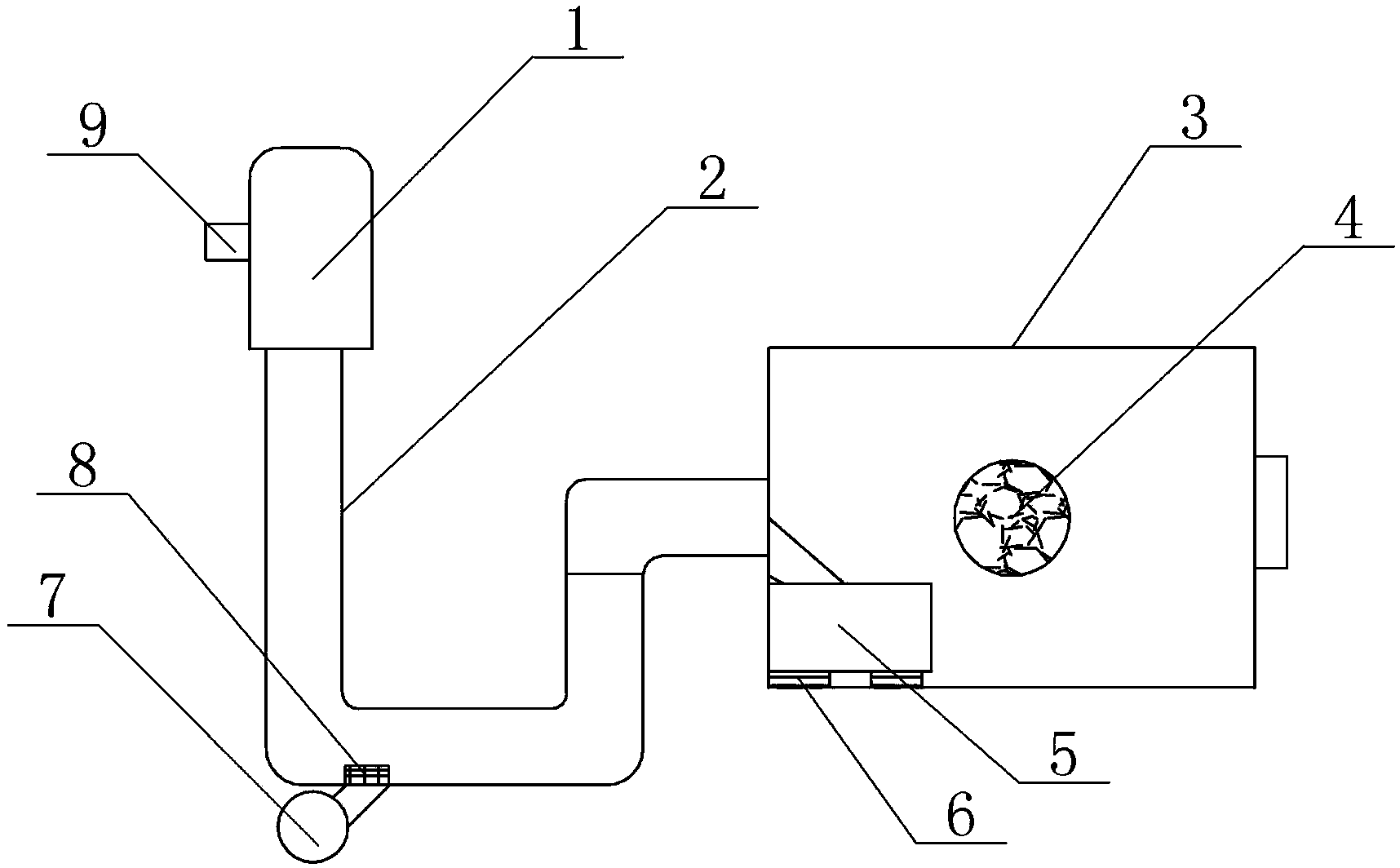

[0017] Such as figure 1 As shown, the present invention provides a flowmeter pipeline dredging device, including a flushing tank 1 connected to the inlet of the U-shaped flow tube 2 and a buffer tank 3 connected to the outlet, and the other side of the buffer tank 3 is provided with a discharge port. The inlet of the buffer box 3 can be connected with the outlet of the U-shaped flow tube 2 by a pipeline, and a centrifugal fan 7 is arranged at the horizontal pipeline section of the U-shaped flow tube 2, and the horizontal pipeline section of the centrifugal fan 7 and the U-shaped flow tube 2 An aeration pipe 8 is set at the connection, the centrifugal fan 7 is placed outside the U-shaped flow tube, and the aeration tube 8 is placed on the inner wall of the U-shaped flow tube 2; Diaphragm pump 5, on the buffer tank 3, the inlet correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com