Automatic central shaft assembling machine of permanent-magnet claw pole type stepping motor

A technology for automatic assembly machines and stepping motors, which is applied in the direction of electric components, electromechanical devices, and manufacturing motor generators, etc. It can solve the problems of restricting motor output, low efficiency, and high work intensity of operators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

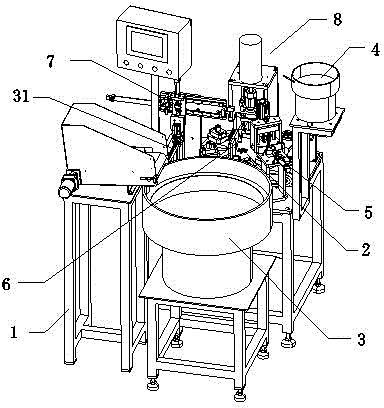

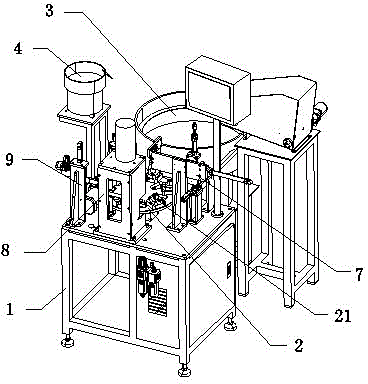

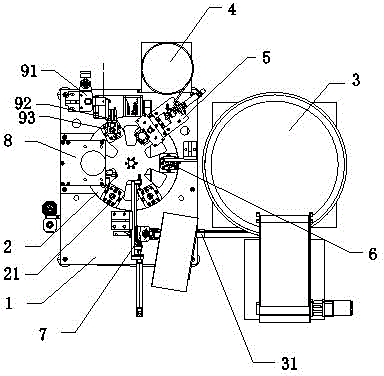

[0027] refer to Figure 1 to Figure 5 , Figure 1 to Figure 5 It is a structural schematic diagram of a specific embodiment of the present invention. As shown in the figure, the permanent magnet claw pole type stepper motor central shaft automatic assembly machine includes a frame 1, a turntable 2, a casing vibration feeding plate 3, and a central shaft vibration feeding Disk 4, sending central shaft device 5, detecting central shaft device 6, taking out the casing manipulator 7, pressing device 8, and taking material manipulator 9.

[0028] As shown in the figure, the turntable 2 is arranged on the frame 1 through a rotating device, and six casing positioning jigs 21 are arranged on the turntable 2, and the casing positioning jigs 21 are respectively provided with 1. The groove and hole position corresponding to the central axis. The rotating device includes a driving motor 22 and a belt transmission mechanism 23. The driving motor 22 is connected to the turntable 2 through ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap