Guide rail type adhesion construction lifter and construction method thereof

A technology for construction elevators and construction methods, which is applied to elevators, lifting equipment in mines, elevators in buildings, etc., can solve problems such as installation and demolition, hidden dangers, and impact on construction progress, and save resources, costs, and turnover rates. The effect of raising and lowering costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

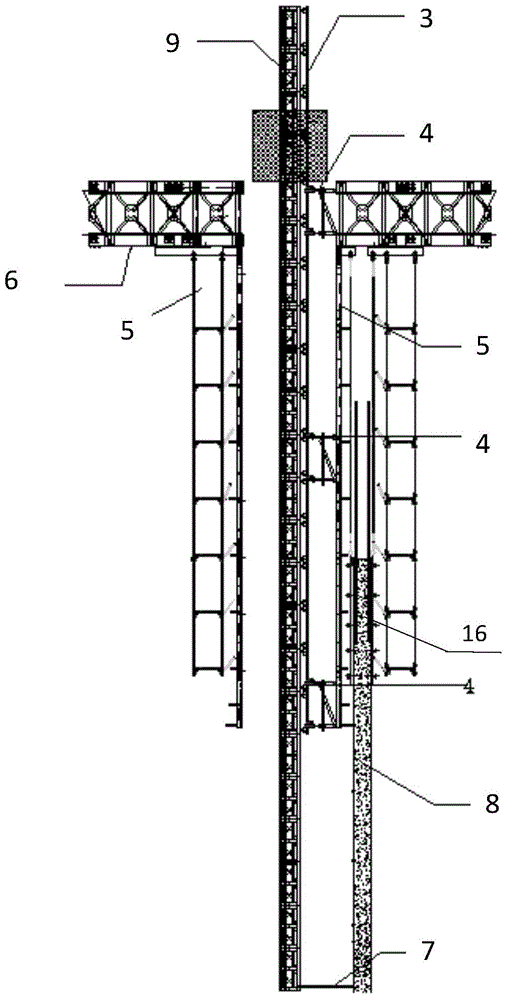

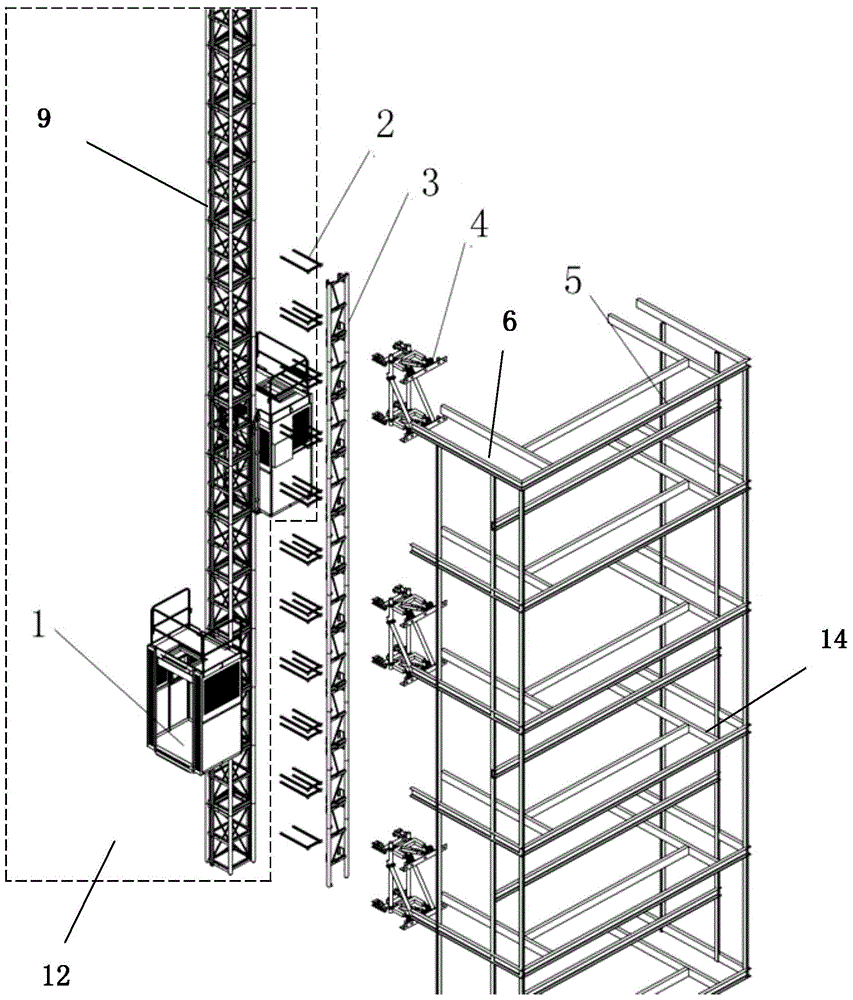

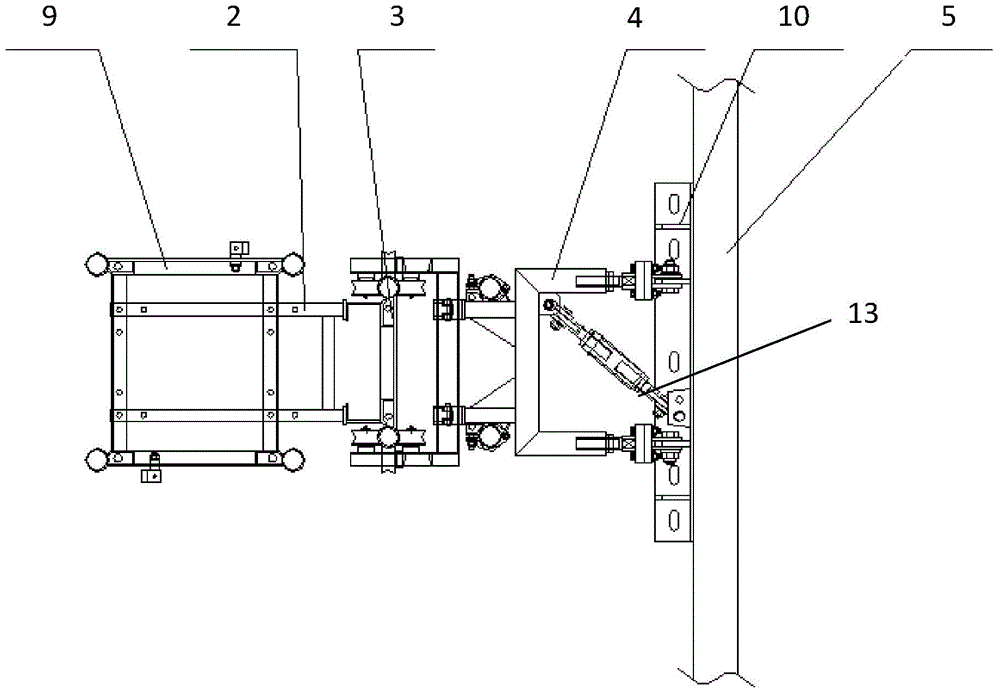

[0040] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 Shown is a guide rail type attachment construction elevator of the present invention, and the rail type attachment construction is completed through the wall attachment type structure of the construction elevator and the mold lifting process.

[0041] In the present invention, the top mold system 14 includes an interconnected steel platform system 6 , a support and jacking system 15 , a top mold hanger system 5 , and a formwork system 16 .

[0042] The entire top mold system 14 is jacked up by the hydraulic cylinder 17 installed at the lower part of the top mold hanger 5. The guide rail attachment method, that is, during the lifting process of the top mold 14, the top mold 14 and the rolling attachment wall 4 together. Lift up, the top mold and the rolling attachment wall roll upward along the single-piece standard section 3, the rolling attachment wall (4) frame body is provided with rollers 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com